Lukas Concrete crushers User Manual

Page 36

36

10.3.2 Replacing or tightening the hoses

Hose connection on the pressure and/or return line is leaking or hoses are defective. Tighten

the hoses on the control valve.

(Please note! Observe torque of M

A

= 40 Nm!)

NOTE when using mono-couplings:

If you want to change the hoses, you must first dismantle the mono-couplings.

CAUTION (when using the mono-coupling system)!

Take care that the port ‘T’ of the recycling unit is always connected to the port ‘T’

of the mono-coupling.

CAUTION (when using the quick-disconnect coupling system)!

The return hose, which is screwed onto port “T” of the recycling unit, must always

be fitted with a male quick-disconnect coupling.

However the supplying hose line must be fitted with a female quick-disconnect

coupling.

Procedure:

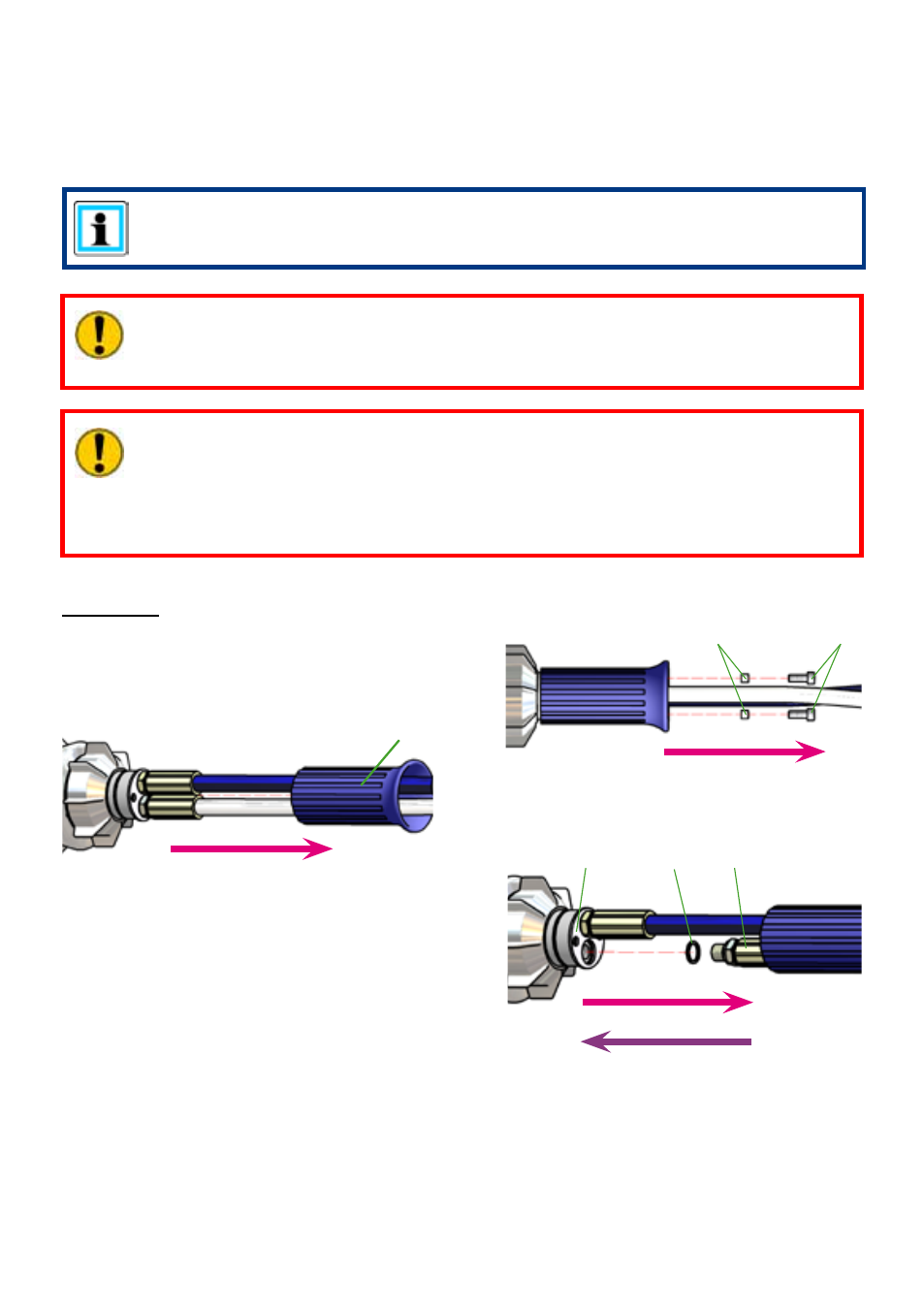

1. Loosen the 2 B screws in the handle sleeve

with quick-disconnect protective sleeves C

(hexagon socket)

2. Remove handle sleeve A and tighten

screwed connection. If necessary, renew

seals.

3. Dismantle hose D and sealing ring E. (This

point is omitted if the hoses are just being

tightened!)

4. Screw the hose with sealing ring back on.

Please ensure that the insulating washer F

is on and correctly assembled.

5. Tighten the hose connection on the control valve. (Please note! Observe the

necessary torque of M

A

= 40 Nm!)

6. Then replace handle sleeve, protective sleeves and screws, tighten (Torque:5 Nm) and

secure it with thread-locking compound (e. g. LOCTITE 243).

B

C

D

E

F

assemble

dismantle

A