General maintenance – Lull 644E-42 Operation Manual User Manual

Page 159

General Maintenance

157

Model 644E

Origin 3/04

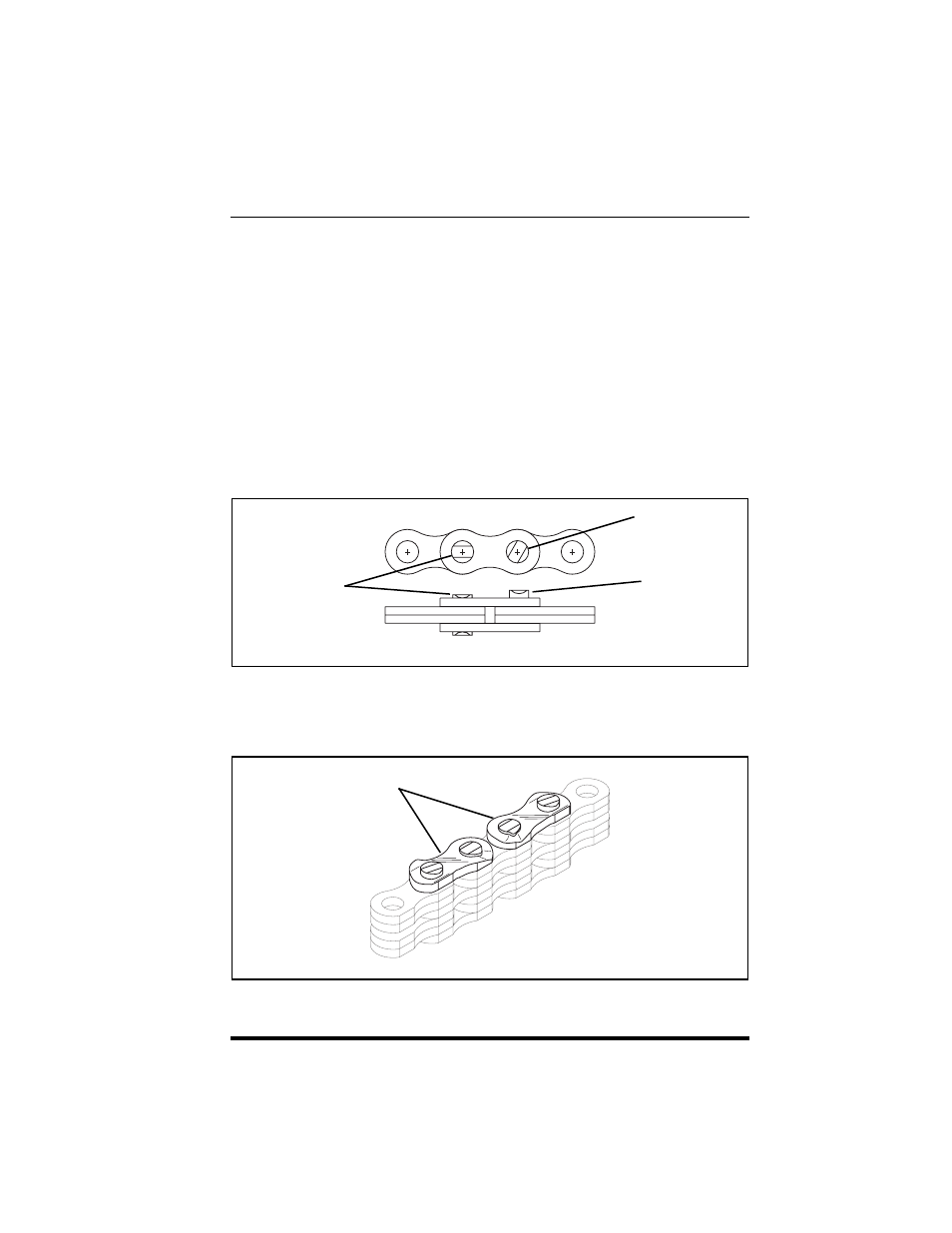

Turning or Protruding Pins

Highly loaded chain, operating with inadequate lubrication can generate

abnormal frictional forces between pin and link plates. When chain is allowed to

operate in this condition, a pin or series of pins, can begin to twist out of a chain,

resulting in failure.

Examine the pin head rivets to determine if the ìVEEî flats are still in correct

alignment (3). Chain with rotated/displaced heads (4) or abnormal pin

protrusion (5) should be replaced immediately.

DO NOT attempt to repair the chain by welding or driving the pin(s) back into

the chain. Once the press fit integrity between outside plates and pins has been

altered, it cannot be restored.

Any wear pattern on the pin heads or the sides of the link plates indicates

misalignment in the system. This condition damages the chain as well as

increases frictional loading and should be corrected. Contact your local Lull

Distributor or the JLG Service Department at (877) 554-5438 or (717) 485-6657

for specific instructions.

Distorted or Battered Link Plates

Distorted or battered link plates (6) on a leaf chain cause tight joints and prevent

flexing.

MM2060

3

5

4

MA9340

6