AEM 30-2905-96 EMS-4 Flying Lead Harness with Fuse and Relay Panel User Manual

Page 12

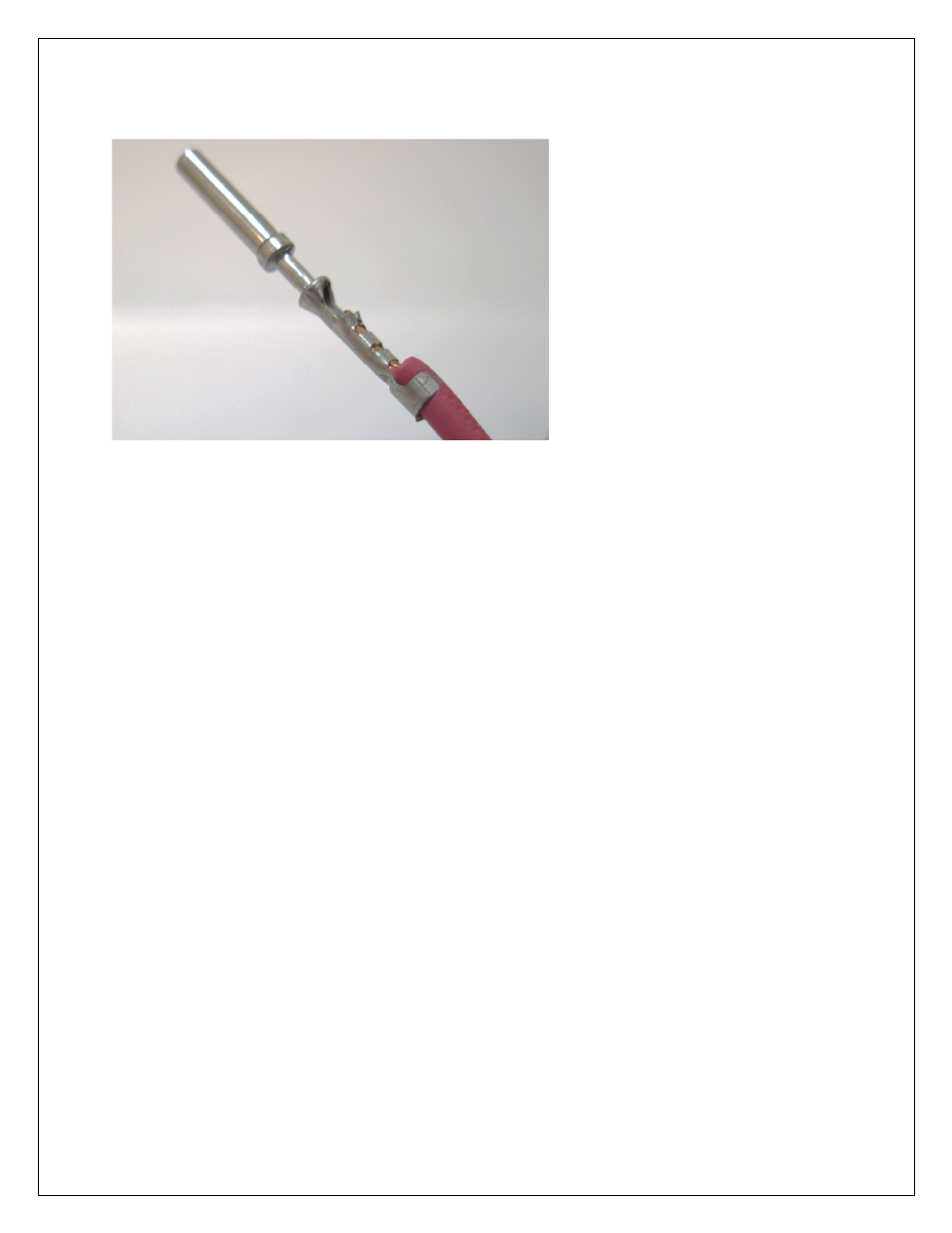

Side View. After crimping, be sure

to do a pull test to make sure the

terminal is properly installed.

General note on wire terminations

A proper wiring job includes proper termination of the wire at the sensor. The wire terminal end

must be moisture tight where it plugs into the sensor and it must have strong, electrically sound

terminals. The preferred method of securing a wire to a terminal is to use a crimp terminal with

NO solder. It is important to use the proper crimping tool for sound terminal construction.

Plastic terminal plugs must have moisture tight seals. Inspect each plug to make sure the seals

are in place. Also, before the plug is installed on the sensor, apply a dab of di-electric grease in

the terminal slots to further aid in corrosion resistance.

If a splice into a wire must be made and no solder-less terminals are available, then you must

properly solder the splice.