4 positioning / installing the machine 6 – Fast & Fluid HA-mII mediumII User Manual

Page 8

4 Positioning / Installing the machine

6

4.1

Conditions for correct positioning

Make sure that the following requirements are met when positioning the machine.

•

Place the machine on a stable, flat surface, and make sure that it is level.

•

Any dry, well ventilated place is suitable. The machine should preferably not be placed in the

sun or near a radiator or other source of heat, since this can cause the pastes to dry out.

•

Maintain a constant ambient temperature of approximately 18

o

C to prevent viscosity changes in

the pastes.

•

Make sure that the machine is connected only to a 230 V/50 Hz or 110 V / 50-60 Hz earthed wall

socket. See the machine plate for correct voltage.

4.2

Installing the machine

4.2.1

Preparation

Note: Tools and fastenings are supplied with the machine. They include a triangular key, ordinary

spanners, cable connectors, screws etc.

•

Remove the triangular key from the installation kit (attached to the door) and remove the panel

at the back of the machine.

•

Remove all the loose components (including monitor stand or printer where applicable) from

inside the machine and the plastic film around the canisters.

•

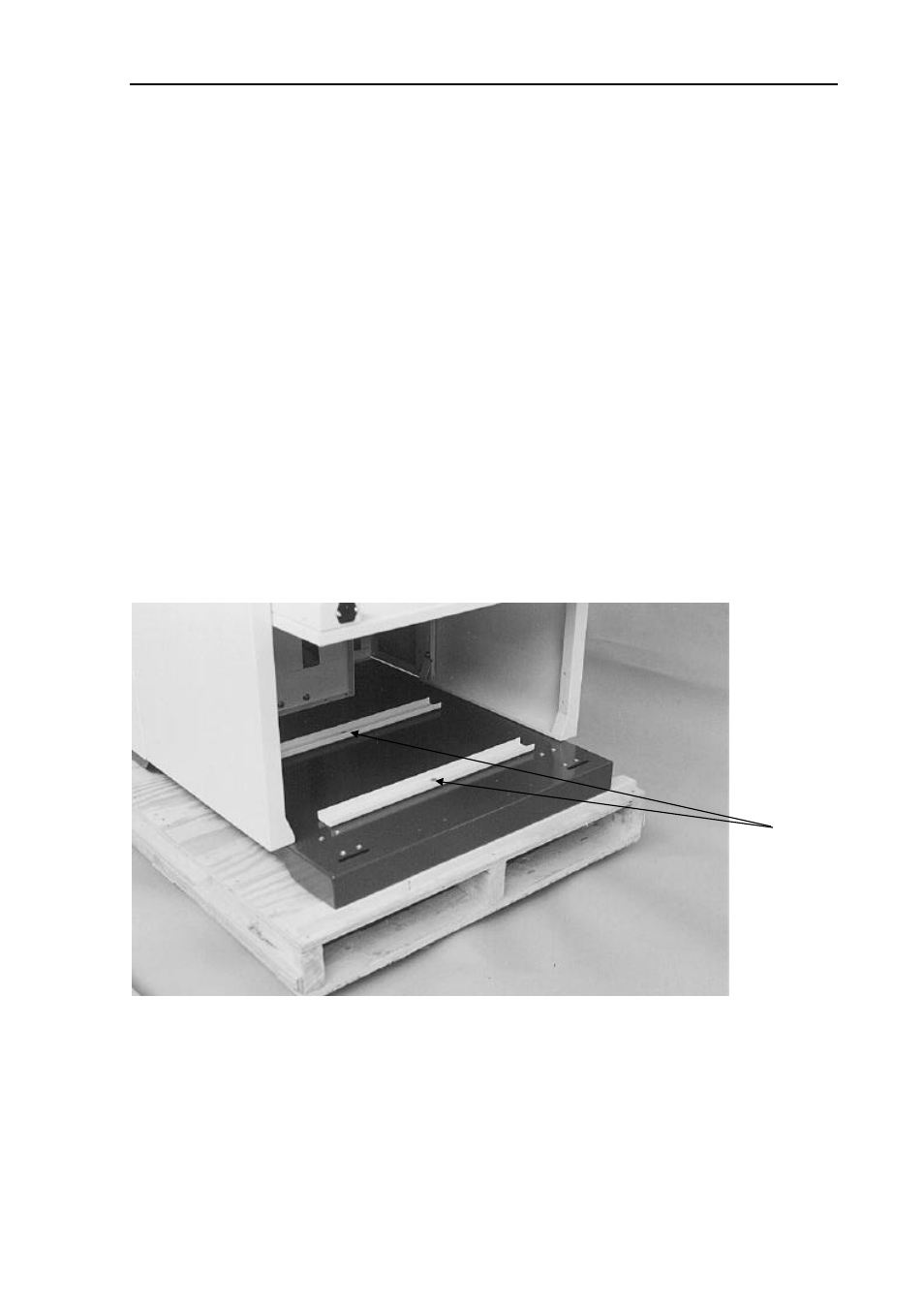

Remove the fastening bolts attaching the machine to the pallet (see figure 1, number 1).

figure 1

1