Bryant Hat Pump 698B User Manual

Page 5

C.

REFRIGERANT TUBING AND FILTER DRIER

CAUTION:

Installation of filter drier in liquid line is

required.

Connect vapor tubing to fittings on outdoor unit vapor service

valve. Connect liquid tubing to filter drier. (See Table 1 and Fig.

9.) Use refrigerant grade tubing. Connect other end of filter drier

to adapter tube on liquid service valve.

D.

SWEAT CONNECTION

CAUTION:

To avoid valve damage while brazing, ser-

vice valves must be wrapped in a heat-sinking material

such as a wet cloth.

Wrap service valves and filter drier with a wet cloth or heat-

sinking material. Braze connections using either silver bearing or

non-silver bearing brazing material. Do not use soft solder

(materials which melt below 800°F). Consult local code require-

ments.

CAUTION:

To prevent damage to unit or service valves,

observe the following:

• Use a brazing shield.

• Wrap service valves with wet cloth or use a heat sink

material.

E.

LEAK CHECKING

Leak test all joints in indoor, outdoor, and refrigerant tubing.

F.

EVACUATE REFRIGERANT TUBING AND

INDOOR COIL

CAUTION:

To avoid compressor damage never use the

system compressor as a vacuum pump.

Refrigerant tubes and indoor coil must be evacuated using the

recommended deep vacuum method of 500 microns. The alternate

triple evacuation method may be used if the procedure outlined

below is followed.

IMPORTANT:

Never open system under vacuum to atmosphere

without first breaking it open with nitrogen.

TABLE 2—ACCESSORY USAGE

ACCESSORY

REQUIRED FOR LONG-LINE

APPLICATIONS

*

(OVER 50 FT)

REQUIRED FOR SEA-COAST

APPLICATIONS

*

(WITHIN 2 MILES)

Coastal Filter

No

Yes

Support Feet

No

Recommended

Puron® Hard Shutoff TXV

Yes†

Yes†

Puron® Liquid-Line Solenoid Valve for Heating

LHALS0401LLS

No

* For tubing line sets between 50 and 175 ft, or more than 20 ft vertical differential refer to Application Guideline and Service Manual for Residential Split-System Air

Conditioners and Heat Pumps using Puron® Refrigerant.

† Required for all applications.

TABLE 3—REQUIRED LIQUID-LINE TEMPERATURE (°F)

LIQUID PRESSURE AT

SERVICE VALVE

(PSIG)

REQUIRED SUBCOOLING TEMPERATURE

(°F)

5

10

15

20

174

56

51

46

41

181

58

53

48

43

188

61

56

51

46

195

63

58

53

48

202

65

60

55

50

209

67

62

57

52

216

69

64

59

54

223

71

66

61

56

230

73

68

63

58

237

75

70

65

60

244

77

72

67

62

251

79

74

69

64

258

81

76

71

66

265

82

77

72

67

272

84

79

74

69

279

86

81

76

71

286

88

86

78

73

293

89

84

79

74

300

91

86

81

76

307

93

88

83

78

314

94

89

84

79

321

96

91

86

81

328

97

92

87

82

335

99

94

89

84

342

100

95

90

85

349

102

97

92

87

356

103

98

93

88

363

105

100

95

90

370

106

101

96

91

377

107

102

97

92

384

109

104

99

94

391

110

105

100

95

398

112

107

102

97

405

113

108

103

98

412

114

109

104

99

419

115

110

105

100

426

117

112

107

102

433

118

113

108

103

440

119

114

109

104

447

120

115

110

105

454

122

117

112

107

461

123

118

113

108

468

124

119

114

109

475

125

120

115

110

482

126

121

116

111

489

127

122

117

112

496

129

124

119

114

503

130

125

120

115

510

131

126

121

116

517

132

127

122

117

524

133

128

123

118

531

134

129

124

119

538

135

130

125

120

545

136

131

126

121

552

137

132

127

122

559

138

133

128

123

566

139

134

129

124

573

140

135

130

125

580

141

136

131

126

587

142

137

132

127

594

143

138

133

128

601

144

139

134

129

608

145

140

135

130

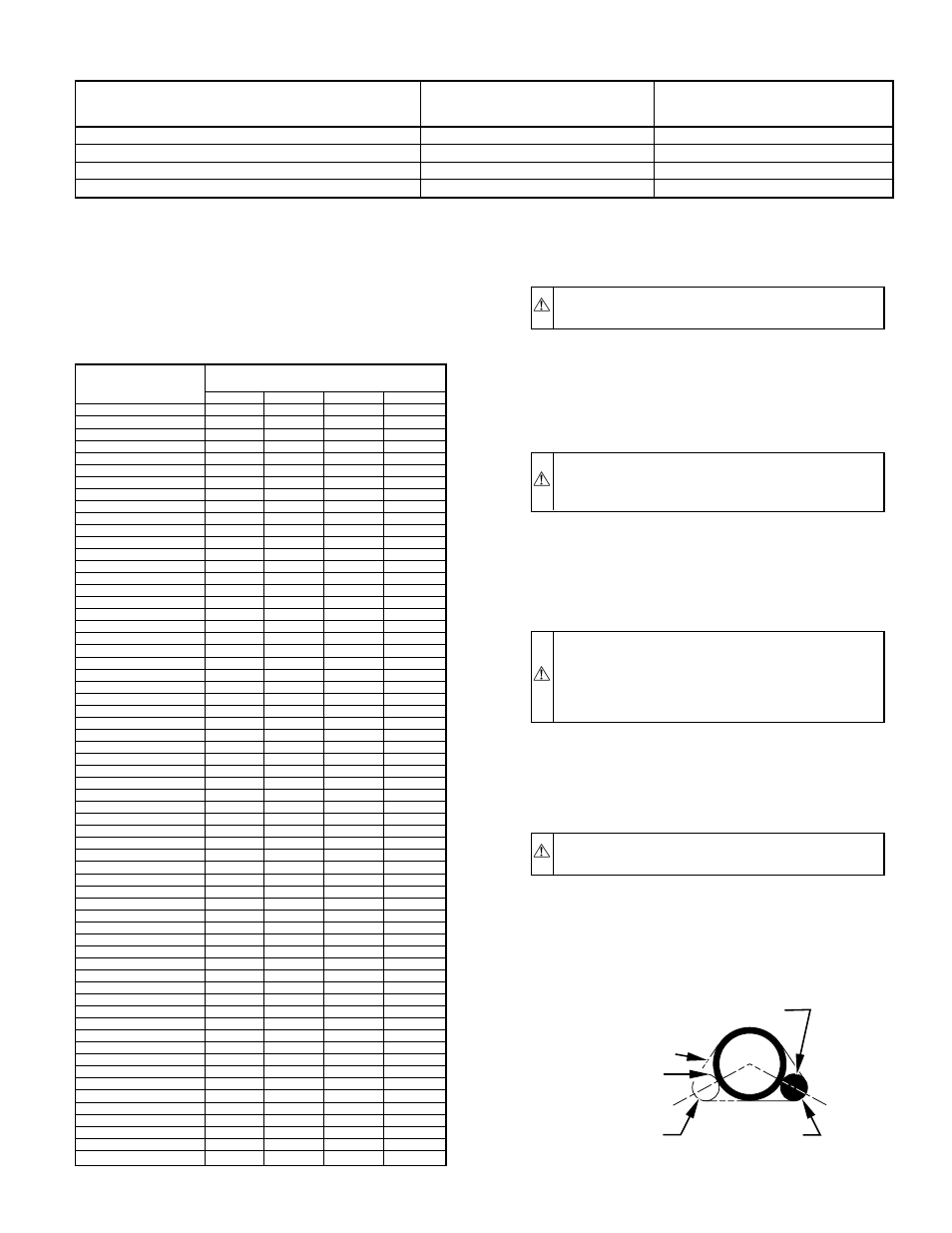

SENSING BULB

STRAP

8 O'CLOCK

4 O'CLOCK

SUCTION

TUBE

A02000

Fig. 7—Positioning of Sensing Bulb

—5—