Bryant Hat Pump 698B User Manual

Page 4

of the Long-Line Guideline section in the Application Guideline

and Service Manual for Residential Split-System Air Conditioners

and Heat Pumps Using Puron® Refrigerant. If required by

Long-Line Application Guideline, install LSV kit Part No.

KHALS0401LLS specifically designed for Puron® Heat Pumps.

LSV should be installed between filter drier and indoor coil as

close as possible to filter drier. Follow the Installation Instructions

included with accessory kit.

IMPORTANT:

Flow arrow must point toward outdoor unit.

VII.

MAKE PIPING CONNECTIONS

WARNING:

Relieve pressure and recover all refrigerant

before system repair or final unit disposal to avoid

personal injury or death. Use all service ports and open all

flow-control devices, including solenoid valves.

CAUTION:

Do not leave system open to atmosphere

any longer than minimum required for installation. POE

oil in compressor is extremely susceptible to moisture

absorption. Always keep ends of tubing sealed during

installation.

CAUTION:

To prevent compressor damage DO NOT

bury more than 36 in. of refrigerant tubing. If ANY

tubing is buried, provide 6-in. vertical rise at service

valve.

Outdoor units may be connected to indoor section using accessory

tubing package or field-supplied refrigerant grade tubing of correct

size and condition. Tubing diameters listed in Table 1 are adequate

for equivalent lengths up to 50 ft For tubing requirements beyond

50 ft, substantial capacity and performance losses can occur.

Follow the recommendations in the Application Guideline and

Service Manual for Residential Split-System Air Conditioners and

Heat Pumps Using Puron® Refrigerant to minimize losses. Refer

to Table 1 for field tubing diameters. Refer to Table 2 for

accessory requirements.

If refrigerant tubes or indoor coil are exposed to atmosphere, they

must be evacuated to 500 microns to eliminate contamination and

moisture in the system. Do not leave system open to atmosphere

any longer than minimum required for installation. POE oil in

compressor is extremely susceptible to moisture absorption. Al-

ways keep ends of tubing sealed during installation.

A.

OUTDOOR

UNIT

CONNECTED

TO

FACTORY-

APPROVED INDOOR UNIT

These outdoor units are carefully evaluated and listed with specific

indoor coils for proper system performance.

IMPORTANT:

Do not apply indoor coils which are not factory

approved to these units.

IMPORTANT:

For 036 size units matched with the FV/FK005 or

FV/FK006 and the 698BNX048 matched with the FV/FK006, a

piston change is required. Refer to the KHAPX0201BPA Instal-

lation Instructions for details.

B.

INSTALL ADAPTER TUBE

1. Remove plastic retainer holding outdoor piston in liquid

service valve.

2. Check to be sure outdoor piston is properly installed in

liquid service valve.

3. Locate plastic bag taped to unit containing adapter tube.

4. Remove Teflon washer from bag and install on open end of

liquid service valve. (See Fig. 8.)

5. Remove adapter tube from bag and connect threaded nut to

liquid service valve. Tighten nut finger tight and then with

wrench an additional 1/2 turn (15 ft-lb). DO NOT OVER

TIGHTEN!

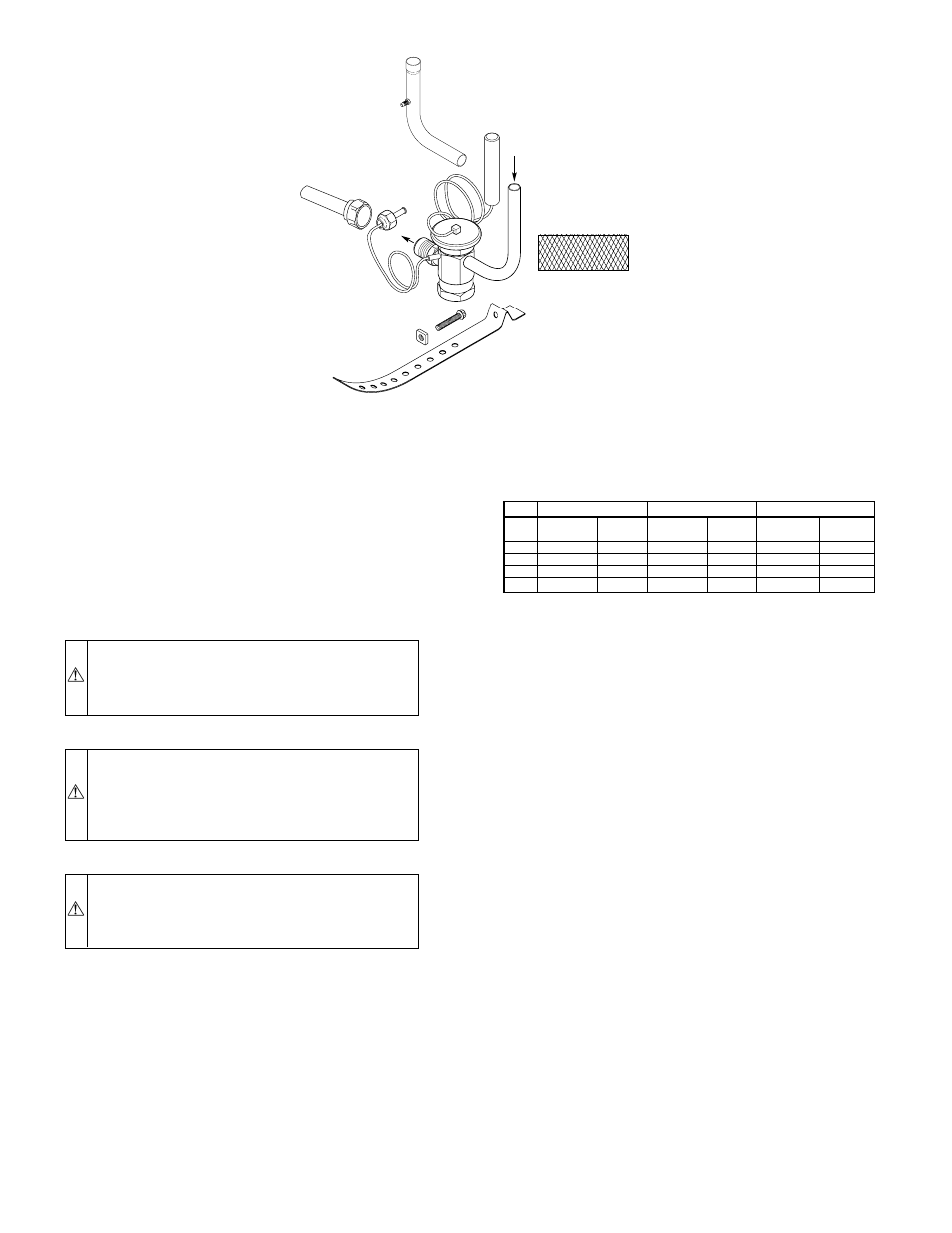

Fig. 6—TXV Kit Contents

A01418

A

B

D

INLET

COIL

E

BULB

INSULATION

TAPE

C

TABLE 1—REFRIGERANT CONNECTIONS AND

RECOMMENDED LIQUID AND VAPOR TUBE

DIAMETERS (IN.)

UNIT

LIQUID

VAPOR

VAPOR (LONG-LINE)

SIZE

Connection

Diameter

Tube

Diameter

Connection

Diameter

Tube

Diameter

Connection

Diameter

Tube

Diameter

024

3/8

3/8

5/8

5/8

5/8

3/4

036

3/8

3/8

3/4

3/4

3/4

7/8

048

3/8

3/8

7/8

7/8

7/8

7/8

060

3/8

3/8

7/8

1-1/8

7/8

1-1/8

Notes:

1. Tube diameters are for lengths up to 50 equivalent ft and/or 20 ft vertical

differential.

2. Do not increase or decrease tubing sizes.

3. If required by local codes, Pressure Guard™ kit is available. See Product

Data Sheet for part numbers.

—4—