A b c d – Bryant Hat Pump 698B User Manual

Page 11

Adjust charge in both heating and cooling by following procedure

shown on charging tables located on pink charging label on back

side of access panel.

NOTE:

Unit is to be charged in high capacity only. Charging in

low capacity may cause compressor chattering and possible

damage to the compressor.

B.

COOLING ONLY PROCEDURE

1. Operate unit a minimum of 15 minutes before checking

charge.

2. Measure liquid service valve pressure by attaching an

accurate gage to service port.

3. Measure liquid line temperature by attaching an accurate

thermistor type or electronic thermometer to liquid line near

outdoor coil.

4. Refer to charging label for required subcooling tempera-

tures.

5. Refer to Table 3. Find the point where required subcooling

temperature intersects measured liquid service valve pres-

sure.

6. To obtain required subcooling temperature at a specific

liquid line pressure, add refrigerant if liquid line tempera-

ture is higher than indicated or reclaim refrigerant if

temperature is lower. Allow a tolerance of ± 3°F.

C.

HEATING CHECK CHARGE PROCEDURE

To check system operation during heating cycle, refer to the

Heating Pump Charging Instructions on outdoor unit. This chart

indicates whether a correct relationship exists between system

operating pressure and air temperature entering indoor and outdoor

units. If pressure and temperature do not match on chart, system

refrigerant charge may not be correct. Do not use chart to adjust

refrigerant charge.

NOTE:

In heating mode, check refrigerant charge only when

pressures are stable. If accessory vapor pressure switch is applied

and operating conditions cause vapor pressure switch and thereby

outdoor fan to cycle, check refrigerant charge in cooling or lower

indoor dry bulb temperature. If in doubt, remove charge and weigh

in correct refrigerant charge.

NOTE:

When charging is necessary during heating season,

charge must be weighed in accordance with unit rating plate ±0.6

oz/ft of 3/8-in. liquid line above or below 15 ft respectively.

EXAMPLE:

To calculate additional charge required for a

25-ft line set:

25 ft - 15 ft = 10 ft X 0.6 oz/ft = 6 oz of

additional charge.

XIII.

SYSTEM FUNCTIONS AND SEQUENCE OF OP-

ERATION

The outdoor unit control system has special functions. The

following is an overview of the two-speed control functions:

A.

COOLING OPERATION

This product utilizes a 2-stage cooling indoor thermostat. With a

call for first stage cooling (Yl), the outdoor fan and low capacity

compressor are energized. If low capacity cannot satisfy cooling

demand, high capacity is energized (Yl and Y2 or just Y2) by the

second stage of indoor thermostat. After second stage is satisfied,

the unit returns to low-capacity operation until first stage is

satisfied or until second stage is required again. When both one

stage and two stage cooling are satisfied, the compressor will shut

off.

NOTE:

Outdoor fan motor will continue to operate for one

minute after compressor shuts off, when outdoor ambient is greater

than 100°F.

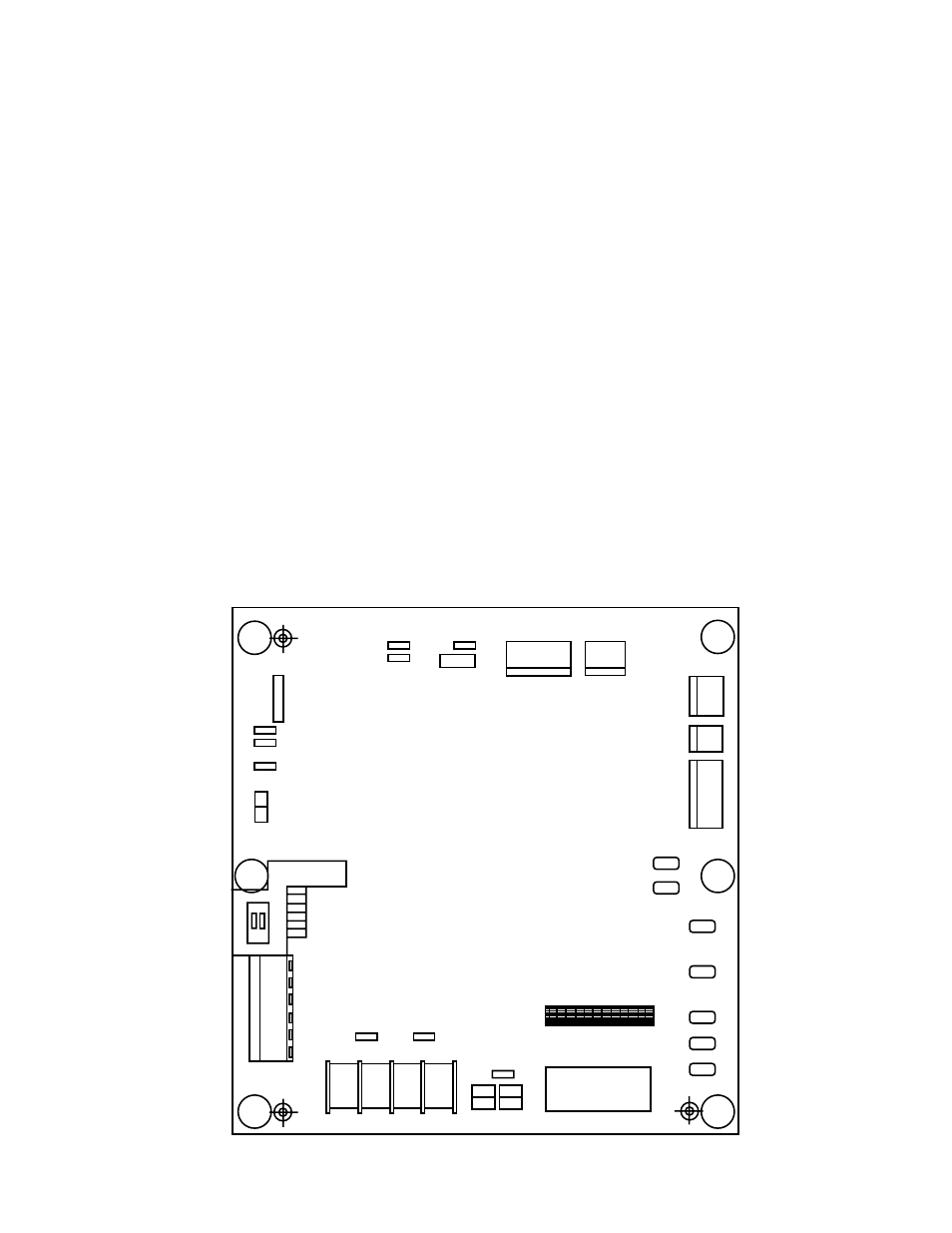

Fig. 15—Control Board

A00379

CEBD430439-03A

SS0ID

PL1

PL2

HP/A

C

SEV

RV

S

C

HI

LO

PL3

PL4

PL5

OCT O

A

T HPS LPS

PWM2

PWM1

BRN

BLU

BLK

YEL

RED

CCH L2 ODF

VH

VC

C E S O 1 3 0 0 7 8 - 0 0

K1

CEPL130439-01

C O M M S TAT U S

D51

D52

A B C D

0

Y2

Y1

W1

C

R

120

30

60

60

30

90

DEFROST

TIME (MIN)

R39

R44

R42

C18

C16

R36

FORCED

DEFR

OST

1

1

1

S1

R89

R91

R87

R86

R85

J1

C31

R61

R65

R38

R33

C2

R9

1 2

—11—