Thermistor curve – Bryant Hat Pump 698B User Manual

Page 12

NOTE:

When two-speed unit is operating in low-capacity cool-

ing, system vapor (suction) pressure will be higher than a standard

single-speed system or high-speed operation. This normal opera-

tion is due to the reduced capacity operating with typically larger

indoor and outdoor coils.

B.

ONE MINUTE SPEED CHANGE TIME DELAY

When compressor changes speeds from high to low or low to high,

there is a 1-minute time delay before compressor restarts. The

outdoor fan motor remains running.

C.

HEATING OPERATION

This product utilizes a 3-stage heating indoor thermostat. With a

call for first stage heating (Y1), the outdoor fan and low capacity

compressor are energized. If low capacity cannot satisfy heating

demand, high capacity is energized (Y1 and Y2) by the second

stage of the indoor thermostat. Auxiliary or back up heat is

controlled by third stage (W1). After second stage of heat is

satisfied, the unit returns to low capacity operation until first stage

is satisfied or until second stage is required again. When both one

stage and two stage heating are satisfied, the compressor will shut

off. See thermostat Installation Instructions for more staging

information.

NOTE:

If unit has not operated within the past 12 hr or following

a unit power-up, upon the next thermostat high- or low-speed

demand, unit operates for a minimum of 5 minutes on high

speed.

D.

STATUS FUNCTION LIGHTS

A system control STATUS function light is located on the outdoor

unit control board. (See Fig. 15). The STATUS light provides

signals for several system operations. See Table 4 for codes and

definitions. Table 4 also provides the order of signal importance.

NOTE:

Only one code will be displayed on the outdoor unit

control board (the most recent, with the highest priority).

E.

FACTORY DEFAULTS

Factory defaults have been provided in the event of failure of

outdoor air thermistor and/or outdoor coil thermistor. Refer to

Table 6 for default and function.

F.

COMPRESSOR OPERATION

When the compressor operates in two-capacity operation, the

motor rotates clockwise. Both the lower and upper pistons are

eccentric with the rotating crankshaft, and both compress refrig-

erant. When the compressor operates in single capacity the motor

reverses direction (rotates counterclockwise). The lower piston

becomes idle and the upper piston compresses refrigerant. During

single-capacity operation the “start” and “run” windings are

reversed.

G.

CRANKCASE HEATER OPERATION

The two-speed control energizes the compressor crankcase heater

during unit’s off cycle.

H.

OUTDOOR FAN MOTOR OPERATION

The two-speed control energizes outdoor fan any time compressor

is operating. The outdoor fan remains energized during the

1-minute speed change time delay and if a pressure switch or

compressor overload should trip. Outdoor fan motor will continue

to operate for one minute after the compressor shuts off when the

outdoor ambient is greater than 100°F.

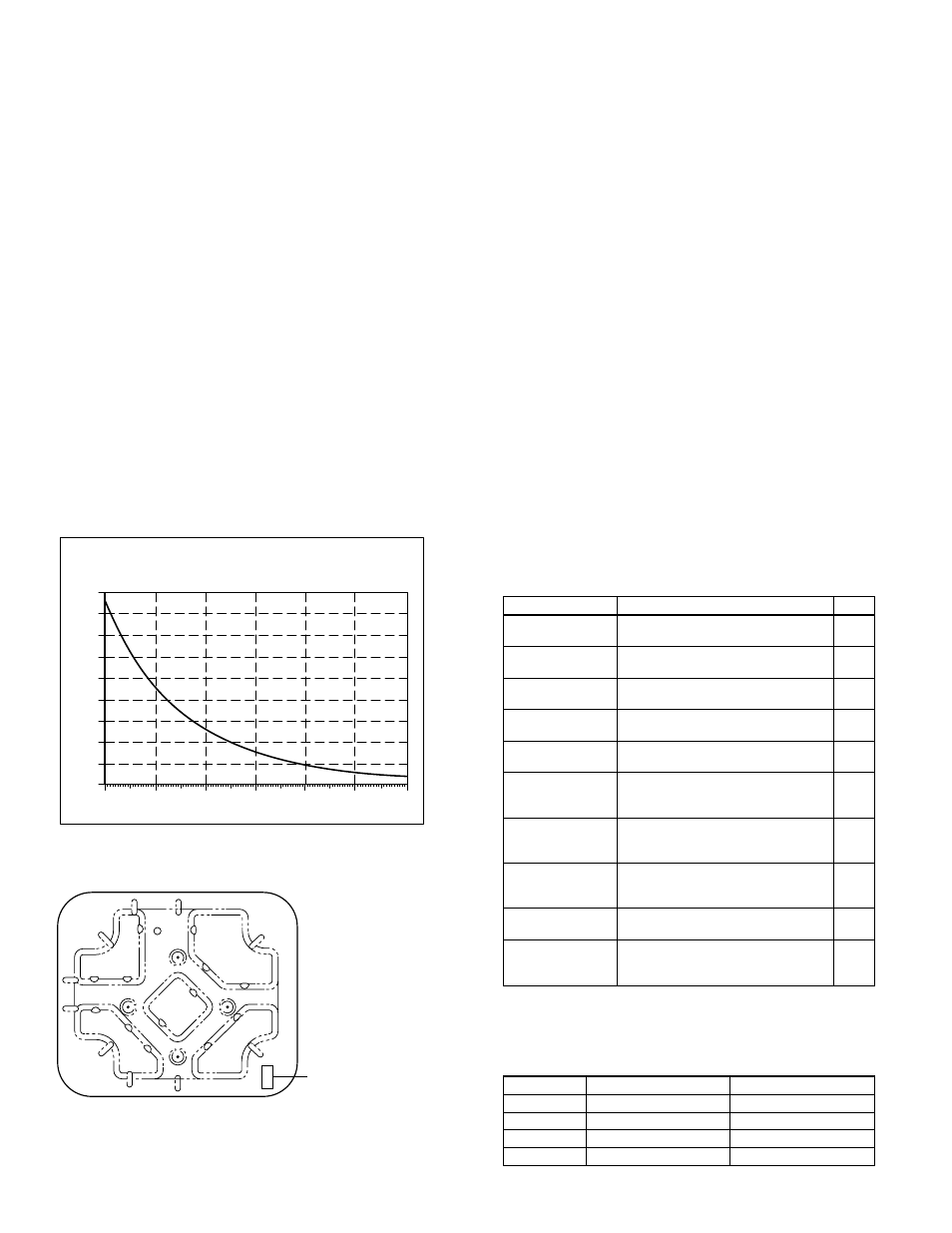

Fig. 16—Resistance Values Versus Temperature

A91431

0

10

20

30

40

50

60

70

80

90

0

20

40

60

80

100

120

TEMPERATURE (DEG. F)

RESISTANCE (KOHMS)

THERMISTOR CURVE

Fig. 17—View from Top of Base Pan

A02218

Control Box

Side of Unit

THERMISTOR PLACED

UNDERNEATH BASE PAN

(ATTACHED TO BASE PAN

WITH ADHESIVE)

TABLE 4—LED CONTROL FUNCTION LIGHT CODE

CODE

DEFINITION

*

Constant flash

No pause

No demand

Stand by

10

1 flash

w/pause

Low-speed operation

9

2 flashes

w/pause

High-speed operation

8

3 flashes

w/pause

Outdoor ambient thermistor failure

7

4 flashes

w/pause

Outdoor coil thermistor failure

6

3 flashes

pause

4 flashes

Thermistor out of range†

5

5 flashes

pause

1 flash

Low pressure switch trip

4

5 flashes

w/pause

2 flashes

High pressure switch trip

3

6 flashes

w/pause

Compressor V

C

/V

H

trip

2

Constant light

No pause

No flash

Board failure

1

* Function light signal order of importance in case of multiple signal request; 1

is most important.

† Check both thermistors to determine which is faulty.

TABLE 5—DEFROST DIP SWITCH SETTINGS

TIME

DIP SWITCH #1

DIP SWITCH #2

30

up

down

60

down

up

90

down

down

120

up

up

—12—