Bryant 4-Way Multipoise Fixed-Capacity Direct-Vent Condensing Gas 340MAV User Manual

Page 33

WARNING:

Blower access panel door switch opens

115-v power to control center. No component operation

can occur. Caution must be taken when manually closing

this switch for service purposes. Failure to follow this

warning could result in electrical shock, personal injury,

or death.

4. BRIEFLY short (jumper) TEST, 1/4-in. quick-connect

terminal on control center (adjacent to the LED diagnostic

light) and the C

OM

terminal on thermostat connection block.

(See Fig. 25.)

NOTE:

If TEST to C

OM

terminals are jumpered longer than 2 sec,

LED will flash rapidly, and retrieval request will be ignored.

5. When above items have been completed, the component

test sequence will occur as described in the Component Test

Sequence section above.

NOTE:

Be sure to record the status code which is flashed 4 times

at start of component test for further troubleshooting.

6. After component test is completed and furnace is operating

properly, release blower access panel door switch, replace

blower access panel, and replace main furnace door.

START-UP PROCEDURES

I.

GENERAL

1. Furnace must have a 115-v power supply properly con-

nected and grounded. Proper polarity must be maintained

for correct operation.

NOTE:

Proper polarity must be maintained for 115-v wiring. If

polarity is incorrect, control center LED status light will flash

rapidly and furnace will not operate.

2. Thermostat wire connections at terminals R, W, G, and Y

must be made at 24-v terminal block on control center.

3. Natural gas service pressure must not exceed 0.5 psig

(14-in. wc), but must be no less than 0.16 psig (4.5-in. wc).

4. Blower access panel must be in place to complete 24-v

electrical circuit to furnace.

CAUTION:

These furnaces are equipped with a manual

reset limit switch in burner box. This switch will open if

an overheat condition (rollout) occurs in burner enclo-

sure. Correct inadequate combustion-air supply or im-

proper venting condition and reset switch. DO NOT

jumper this switch.

Before operating furnace, check each manual reset switch for

continuity. If necessary, press button to reset switch.

II.

PRIME CONDENSATE TRAP WITH WATER

CAUTION:

Condensate trap must be PRIMED or

proper draining may not occur. The condensate trap has 2

internal chambers which can ONLY be primed by pour-

ing water into the inducer drain side of condensate trap.

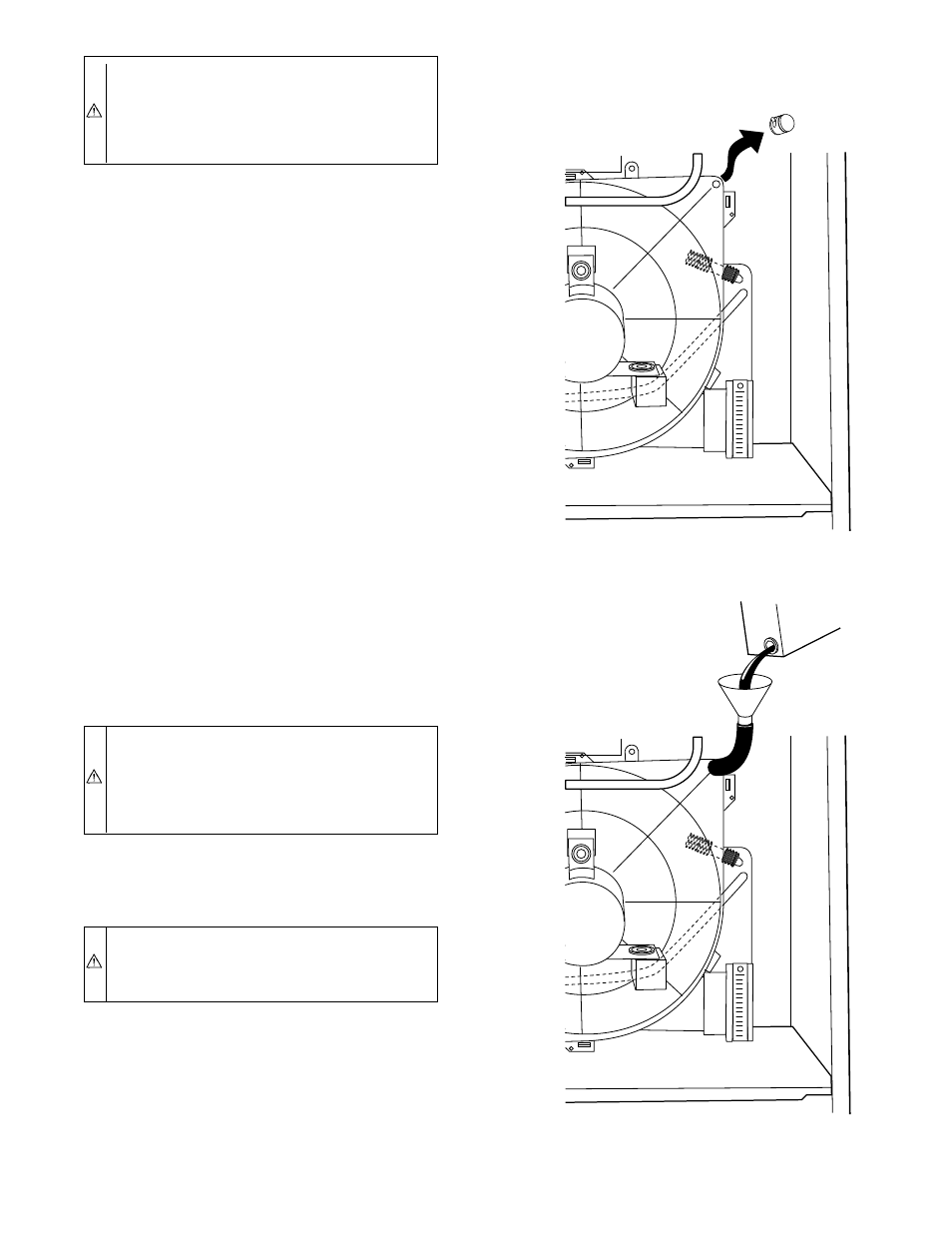

1. Remove upper inducer housing drain connection cap. (See

Fig. 42.)

2. Connect field-supplied 1/2-in. ID tube to upper inducer

housing drain connection.

3. Insert field-supplied funnel into tube.

4. Pour 1 quart of water into funnel/tube. Water should run

through inducer housing, overfill condensate trap, and flow

into open field drain. (See Fig. 43.)

5. Remove funnel and tube from inducer housing and replace

drain connection cap and clamp.

Fig. 43—Filling Condensate Trap

A94209

Fig. 42—Inducer Housing Drain Tube

A94208

—33—