Bryant AIR CONDITIONERS 564A User Manual

Page 16

Inspect the drain pan and condensate drain line when inspecting

the coils. Clean the drain pan and condensate drain by removing all

foreign matter from the pan. Flush the pan and drain tube with

clear water. Do not splash water on the insulation, motor, wiring,

or air filter(s). If the drain tube is restricted, clear it with a

‘‘plumbers snake’’ or similar probe device. Ensure that the

auxiliary drain port above the drain tube is also clear.

V.

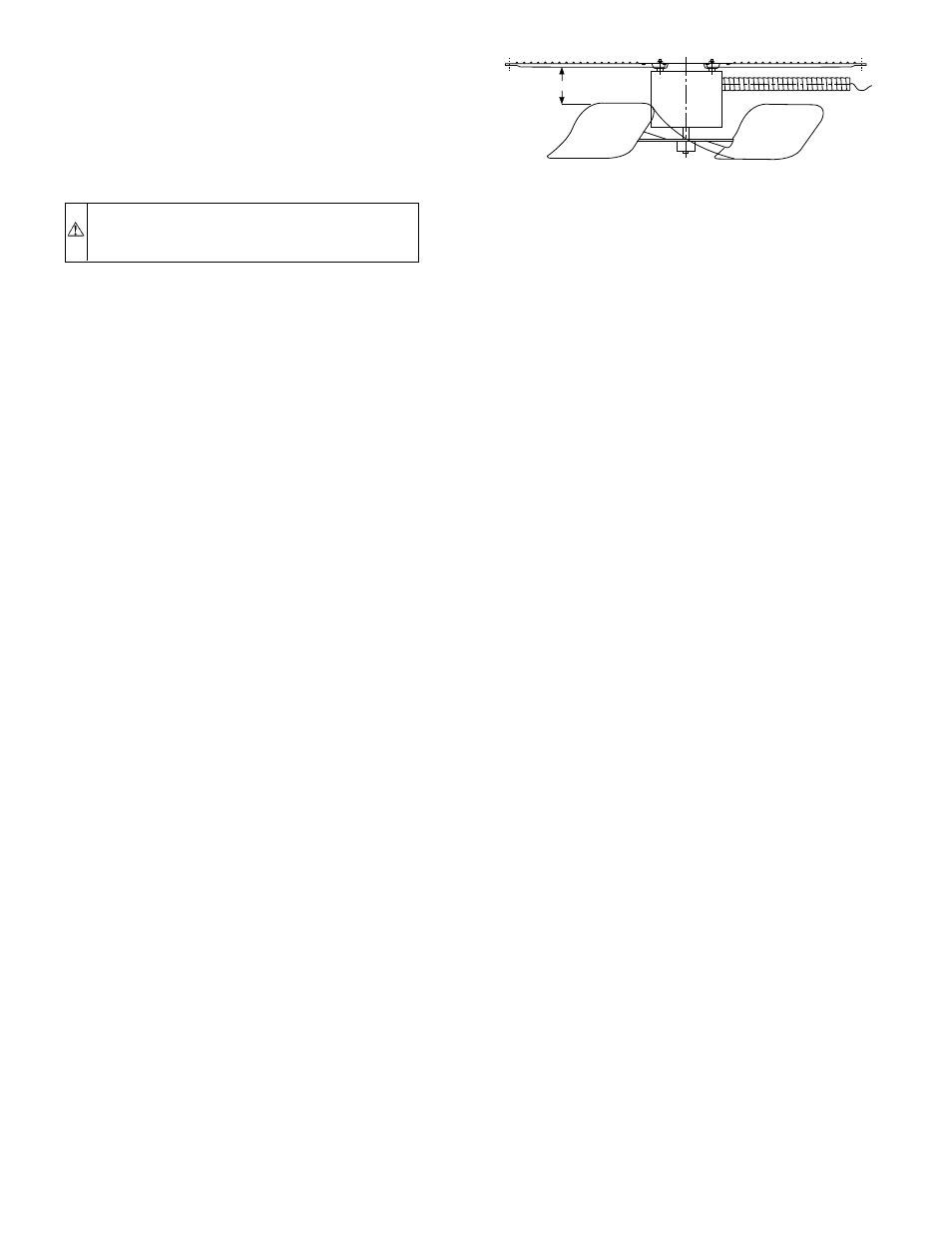

CONDENSER FAN

CAUTION:

Keep the condenser fan free from all ob-

structions to ensure proper cooling operation. Never place

articles on top of the unit. Damage to unit may result.

1. Shut off unit power supply.

2. Remove condenser-fan assembly (grille, motor, motor

cover, and fan) by removing screws and flipping assembly

onto unit top cover.

3. Loosen fan hub setscrews.

4. Adjust fan height as shown in Fig. 21.

5. Tighten setscrews.

6. Replace condenser-fan assembly.

VI.

ELECTRICAL CONTROLS AND WIRING

Inspect and check the electrical controls and wiring annually. Be

sure to turn off the electrical power to the unit.

Remove the top panel to locate all the electrical controls and

wiring. Check all electrical connections for tightness. Tighten all

screw connections. If any smoky or burned connections are

noticed, disassemble the connection, clean all the parts, restrip the

wire end and reassemble the connection properly and securely.

After inspecting the electrical controls and wiring, replace all the

panels. Start the unit, and observe at least one complete cooling

cycle to ensure proper operation. If discrepancies are observed in

operating cycle, or if a suspected malfunction has occurred, check

each electrical component with the proper electrical instrumenta-

tion. Refer to the unit wiring label when making these checkouts.

NOTE:

Refer to the Sequence of Operation section on page 14, as

an aid in determining proper control operation.

VII.

REFRIGERANT CIRCUIT

Inspect all refrigerant tubing connections and the unit base for oil

accumulations annually. Detecting oil generally indicates a refrig-

erant leak.

If oil is detected or if low cooling performance is suspected,

leak-test all refrigerant tubing using an electronic leak-detector, or

liquid-soap solution. If a refrigerant leak is detected, refer to Check

for Refrigerant Leaks section on page 11.

If no refrigerant leaks are found and low cooling performance is

suspected, refer to Refrigerant Charge section on page 11.

VIII.

EVAPORATOR AIRFLOW

The cooling airflow does not require checking unless improper

performance is suspected. If a problem exists, be sure that all

supply- and return-air grilles are open and free from obstructions,

and that the air filter is clean. When necessary, refer to Indoor

Airflow and Airflow Adjustments section on page 14 to check the

system airflow.

IX.

METERING DEVICES

Refrigerant metering devices are fixed orifices and are located in

the inlet header to the evaporator coil.

X.

LIQUID LINE STRAINER

The liquid line strainer (to protect metering device) is made of wire

mesh and is located in the liquid line on the inlet side of the

metering device.

Fig. 21—Condenser-Fan Adjustment

C00021

3.125 in.

—16—