Warning, Pre--start--up – Bryant 574D User Manual

Page 12

12

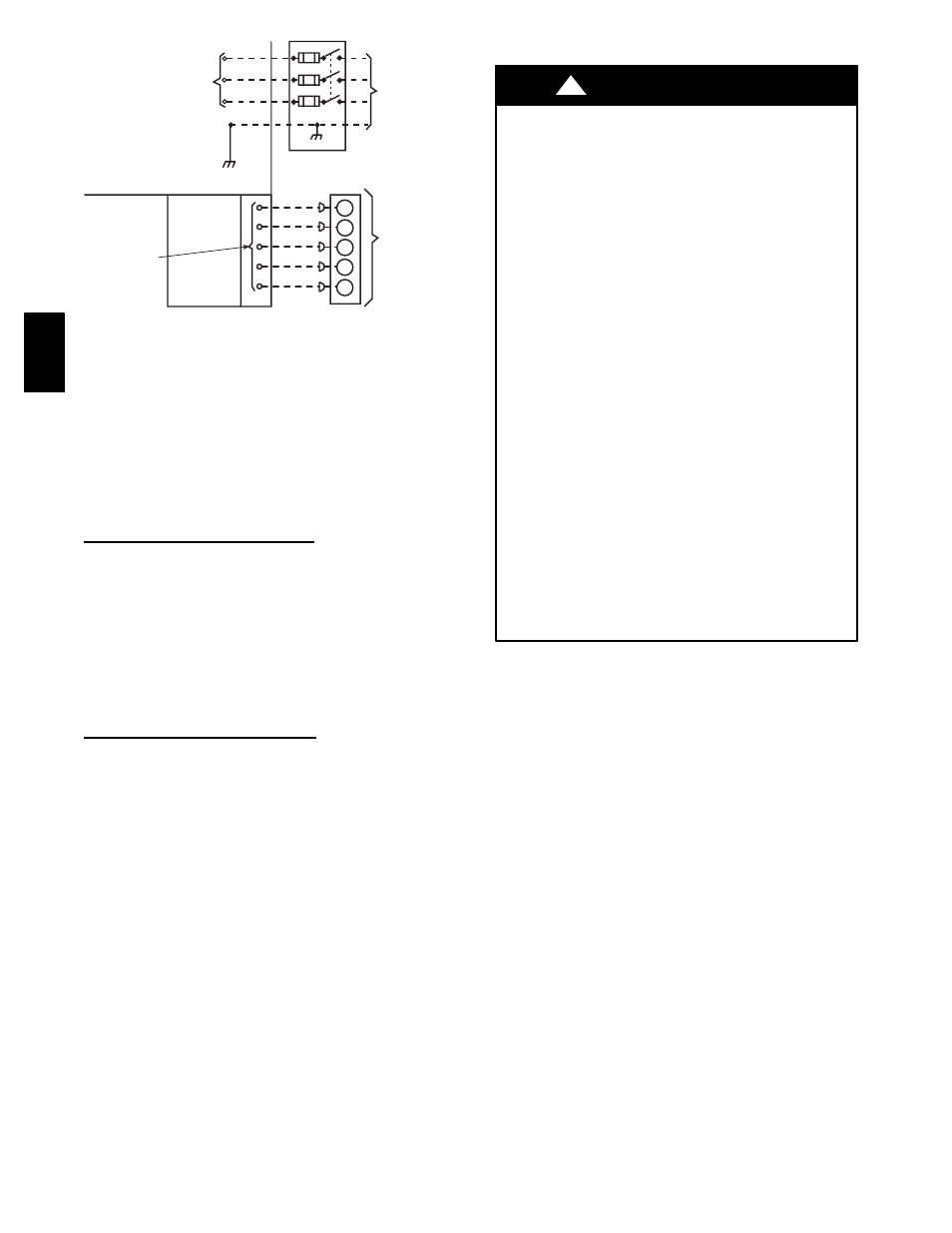

POWER

SUPPLY

FIELD-SUPPLIED

FUSED DISCONNECT

HIGH VOLTAGE

POWER LEADS

(SEE UNIT WIRING

LABEL)

GR

CONTROL BOX

SPLICE BOX

LOW-VOLTAGE

POWER LEADS

(SEE UNIT

WIRING LABEL)

W

Y

G

R

C

WHT(W1)

YEL(Y)

GRN(G)

RED(R)

BRN(C)

THERMOSTAT

(TYPICAL)

A05144

Fig. 11 -- High-- and Control--Voltage Connections

Run the low--voltage leads from the thermostat, through the inlet

hole, and into unit low--voltage splice box.

Locate five 18--gage wires leaving control box. These low--voltage

connection leads can be identified by the colors red, green, yellow,

brown, and white (See Fig. 11). Ensure the leads are long enough

to be routed into the low--voltage splice box (located below right

side of control box). Route leads through hole in bottom of control

box and make low--voltage connections (See Fig. 11). Secure all

cut wires, so that they do not interfere with operation of unit.

HEAT ANTICIPATOR SETTING

The room thermostat heat anticipator must be properly adjusted to

ensure proper heating performance. Set the heat anticipator, using

an ammeter between the W and R terminals to determine the exact

required setting.

NOTE: For thermostat selection purposes, use 0.18 amp for the

approximate required setting. Failure to make a proper heat

anticipator adjustment will result in improper operation, discomfort

to the occupants of the conditioned space, and inefficient energy

utilization; however, the required setting may be changed slightly

to provide a greater degree of comfort for a particular installation.

TRANSFORMER PROTECTION

The transformer is of the energy--limiting type. It is set to withstand

a 30--sec. overload or shorted secondary condition. If an overload

or short is present, correct overload condition and check for blown

fuse on gas control board. Replace fuse as required with correct

size and rating.

PRE--START--UP

FIRE,

EXPLOSION,

ELECTRICAL

SHOCK

HAZARD

Failure to follow this warning could result in personal

injury or death.

1. Follow recognized safety practices and wear protective

goggles when checking or servicing refrigerant system.

2. Do not operate compressor or provide any electric power

to unit unless compressor terminal cover is in place and

secured.

3. Do not remove compressor terminal cover until all

electrical sources are disconnected and tagged.

4. Relieve and recover all refrigerant from system before

touching or disturbing anything inside terminal box if

refrigerant leak is suspected around compressor

terminals.

5. Never attempt to repair soldered connection while

refrigerant system is under pressure.

6. Do not use torch to remove any component. System

contains oil and refrigerant under pressure.

To remove a component, wear protective goggles and

proceed as follows:

a. Shut off electrical power to unit and install

lockout tag.

b. Relieve and reclaim all refrigerant from system

using both high-- and low--pressure ports.

c. Cut component connecting tubing with tubing

cutter and remove component from unit.

d. Carefully unsweat remaining tubing stubs when

necessary. Oil can ignite when exposed to torch

flame.

!

WARNING

Use the Start--Up Checklist supplied at the end of this book and

proceed as follows to inspect and prepare the unit for initial

start--up:

1. Remove access panel.

2. Read and follow instructions on all DANGER, WARNING,

CAUTION, and INFORMATION labels attached to, or

shipped with unit.

3. Make the following inspections:

a. Inspect for shipping and handling damage, such as

broken lines, loose parts, disconnected wires, etc.

b. Inspect for oil at all refrigerant tubing connections and

on unit base. Detecting oil generally indicates a

refrigerant leak.

c. Leak--test all refrigerant tubing connections using

electronic leak detector, or liquid--soap solution. If a

refrigerant leak is detected, see following Check for

Refrigerant Leaks section.

d. Inspect all field-- and factory--wiring connections. Be

sure that connections are completed and tight.

e. Ensure wires do not touch refrigerant tubing or sharp

sheet metal edges.

f. Inspect coil fins. If damaged during shipping and

handling, carefully straighten fins with a fin comb.

574D