Caution – Bryant 574D User Manual

Page 10

10

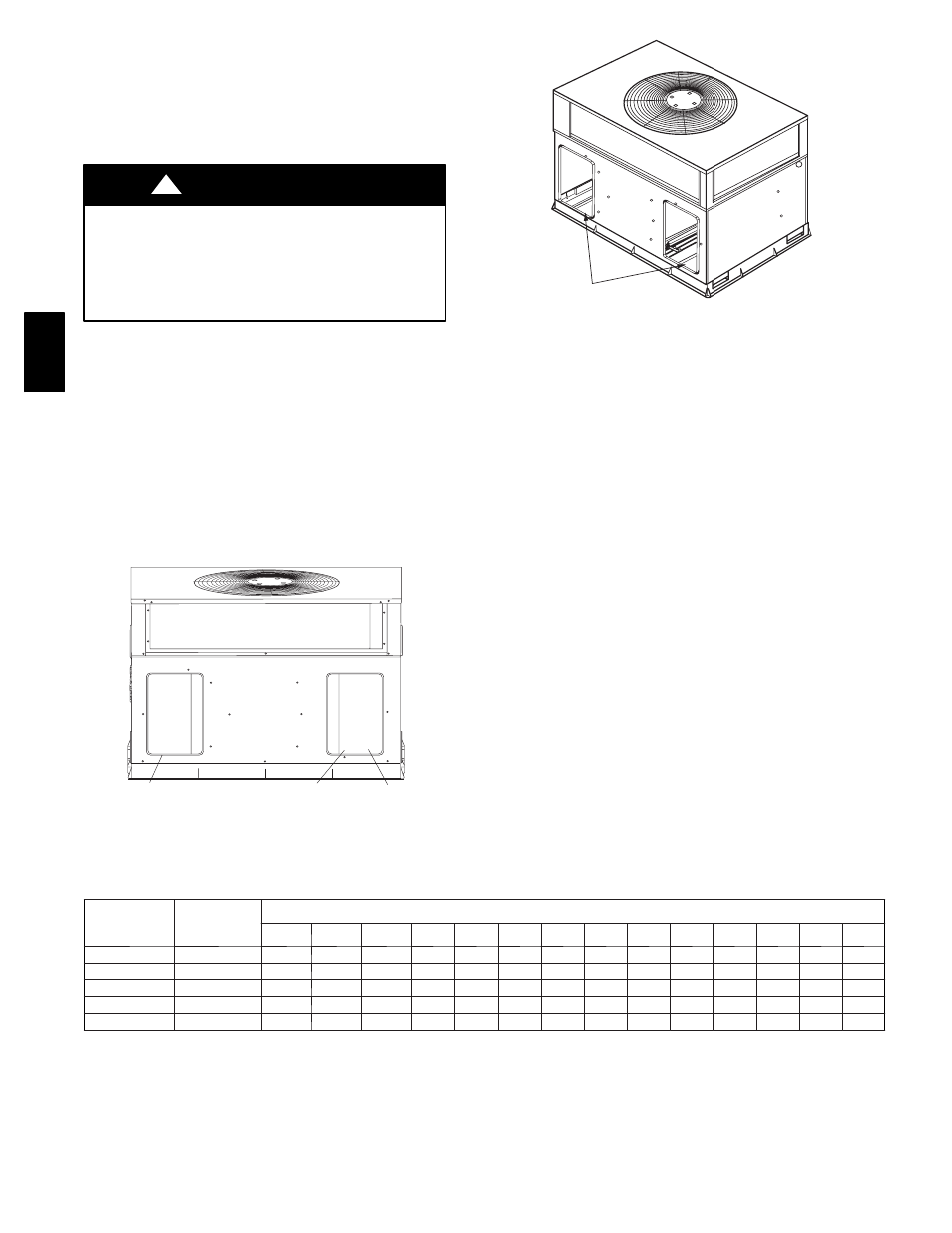

2. Remove horizontal (metal) duct covers to access vertical

(downflow) discharge duct knockouts in unit base.

3. Use a screwdriver and hammer to remove the panels in the

bottom of the unit base (See Fig. 10).

4. If unit ductwork is to be attached to vertical opening flanges

on the unit base (jackstand applications only), do so at this

time.

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property

damage.

Collect ALL screws that were removed. Do not leave

screws on rooftop as permanent damage to the roof may

occur.

CAUTION

!

5. It is recommended that the base insulation around the

perimeter of the vertical return--air opening be secured to

the base with aluminum tape. Applicable local codes may

require aluminum tape to prevent exposed fiberglass.

6. Cover both horizontal duct openings with the provided duct

covers. Ensure opening is air-- and watertight.

7. After completing unit conversion, perform all safety checks

and power up unit.

NOTE: The design and installation of the duct system must be in

accordance with the standards of the NFPA for installation of

nonresidence--type air conditioning and ventilating systems, NFPA

90A or residence--type, NFPA 90B; and/or local codes and

ordinances.

SUPPLY

DUCT

OPENING

RETURN

DUCT

OPENING

VENT HOOD

SHIPPING

LOCATION

A05143

Fig. 9 -- Supply and Return Duct Opening

DUCT COVERS REMOVED

C99012

Fig. 10 -- Vertical Duct Cover Removed

Adhere to the following criteria when selecting, sizing, and

installing the duct system:

1. Units are shipped for horizontal duct installation (by

removing duct covers).

2. Select and size ductwork, supply--air registers, and

return--air grilles according to American Society of Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE)

recommendations.

3. Use flexible transition between rigid ductwork and unit to

prevent transmission of vibration. The transition may be

screwed or bolted to duct flanges. Use suitable gaskets to

ensure weather--tight and airtight seal.

4. All units must have field--supplied filters or accessory filter

rack installed in the return--air side of the unit.

Recommended sizes for filters are shown in Table 1.

5. Size all ductwork for maximum required airflow (either

heating or cooling) for unit being installed. Avoid abrupt

duct size increases or decreases or performance may be

affected.

6. Adequately insulate and weatherproof all ductwork located

outdoors. Insulate ducts passing through unconditioned

space, and use vapor barrier in accordance with latest issue

of Sheet Metal and Air Conditioning Contractors National

Association (SMACNA) and Air Conditioning Contractors

of America (ACCA) minimum installation standards for

heating and air conditioning systems. Secure all ducts to

building structure.

7. Flash, weatherproof, and vibration isolate all openings in

building structure in accordance with local codes and good

building practices.

Table 2 – Maximum Gas Flow Capacity*

NOMINAL

IRON PIPE

SIZE (IN.)

INTERNAL

DIAMETER

(IN.)

LENGTH OF PIPE (FT)†

10

20

30

40

50

60

70

80

90

100

125

150

175

200

1/2

.622

175

120

97

82

73

66

61

57

53

50

44

40

—

—

3/4

.824

360

250

200

170

151

138

125

118

110

103

93

84

77

72

1

1.049

680

465

375

320

285

260

240

220

205

195

175

160

145

135

1--1/4

1.380

1400

950

770

600

580

530

490

460

430

400

360

325

300

280

1--1/2

1.610

2100

1460

1180

990

900

810

750

690

650

620

550

500

460

430

*Capacity of pipe in cu ft of gas per hr for gas pressure of 0.5 psig or less. Pressure drop of 0.5---in. wc (based on a 0.60 specific gravity gas). Refer to Table,

National Fire Protection Association NFPA 54.

{

This length includes an ordinary number of fittings.

574D