Specifications continued – Bryant 550A User Manual

Page 5

—5—

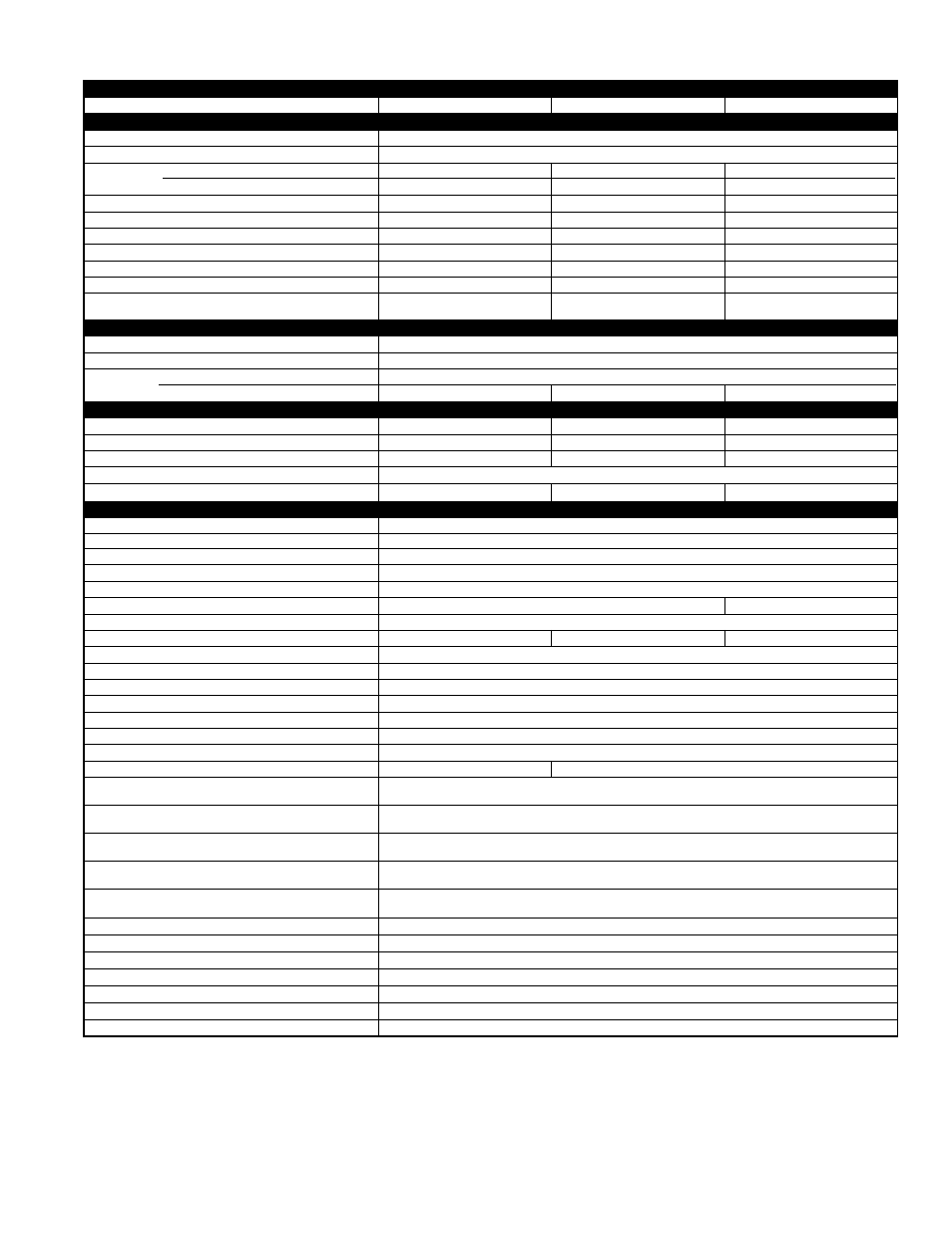

SPECIFICATIONS Continued

* Permissible limits of the voltage range at which the unit will operate satisfactorily. Operation outside these limits may result in unit failure.

† If wire is applied at ambient greater than 30°C (86°F), consult Table 310-16 of the NEC (ANSI/NFPA 70).

The ampacity of nonmetallic-sheathed cable (NM), trade name ROMEX, shall be that of 60°C (140°F) conductors, per the NEC (ANSI/NFPA 70) Article

336-26. If other than uncoated (non-plated), 60 or 75°C (140 or 167°F) insulation, copper wire (solid wire for 10 AWG and smaller, stranded wire for larger

than 10 AWG) is used, consult applicable tables of the NEC (ANSI/NFPA 70).

‡ Length shown is as measured 1 way along wire path between unit and service panel for a voltage drop not to exceed 2%.

** See low-ambient controller Installation Instructions for application.

†† Fan motor with ball bearings required.

N/A — Not Applicable.

NOTE:

Copper wire must be used from service disconnect to unit. All motors/compressors contain internal overload protection.

UNIT SIZE-SERIES

042-F

048-F

060-H

Operating Weight (Lb)

247

295

331

ELECTRICAL

Unit Volts—Hertz—Phase

208/230—60—1

Operating Voltage Range*

187—253

Compressor— Rated Load Amps

18.6

20.5

27.6

Locked Rotor Amps

105.0

109.0

158.0

Condenser Fan Motor—Full Load Amps

1.1

1.4

1.4

Min Unit Ampacity for Wire Sizing

24.4

27.0

35.9

Min Wire Size (60°C Copper) AWG†

10

10

8

Min Wire Size (75°C Copper) AWG†

10

10

8

Max Wire Length (Ft) (60°C Copper)‡

80

73

85

Max Wire Length (Ft) (75°C Copper)‡

76

70

80

Max Branch Circuit Fuse or

Circuit Breaker Size (Amps)

40

40

60

COMPRESSOR & REFRIGERANT

Compressor— Type

Scroll

Temperature & Current Protection

Internal Line Break

Refrigerant— Type

Puron® (R-410A)

Amount (Lb)

8.75

10.13

11.50

CONDENSER COIL & FAN

Coil Face Area (Sq Ft)

18.2

18.2

18.2

Fins per In.—Rows—Circuits

25—1—3

20—2—5

20—2—5

Fan Motor—HP (PSC) & RPM

1/5 & 825

1/4 & 1125

1/4 & 1125

Volts—Hertz—Phase

208/230—60—1

Condenser Airflow (CFM)

2800

3400

3400

OPTIONAL EQUIPMENT

Support Feet

KSASF0101AAA

Coastal Filter

KAACF0801MED

Time Delay Relay

KAATD0101TDR

Cycle Protector

KSACY0101AAA

Crankcase Heater

KAACH1201AAA

Start Assist—Capacitor/Relay Type

KSAHS1501AAA

KSAHS1601AAA

Start Assist—PTC Type

KAACS0201PTC

TXV (Hard Shutoff)

KSATX0301PUR

KSATX0401PUR

KSATX0501PUR

Piston Body

KSAPX0101PIS

Filter Drier (Suction Line)

KH45LG141 (RCD)

Evaporator Freeze Thermostat**

KAAFT0101AAA

Liquid-Line Solenoid Valve

KAALS0201LLS

Winter Start Control**

KAAWS0101AAA

Low-Ambient Pressure Switch

KSALA0301410

MotorMaster® Low-Ambient Controller ††

KSALA0401AAA

Ball Bearing Fan Motor

HC38GE231 (RCD)

HC40GE232 (RCD)

Thermidistat™ Control—

Programmable Thermostat with Humidity Control

TSTATBBPRH01-B

Thermostat—Auto Changeover, 7-Day Programmable,

°F/°C, 1-Stage Heat, 1-Stage Cool

TSTATBBPAC01-B

Thermostat—Auto Changeover, Non-Programmable,

°F/°C, 1-Stage Heat, 1-Stage Cool

TSTATBBNAC01-C

Thermostat—Manual Changeover, 5-2 Day Programmable,

°F/°C, 1-Stage Heat, 1-Stage Cool

TSTATBBSAC01

Builder’s Thermostat—Manual Changeover,

Non-Programmable, °F/°C, 1-Stage Heat, 1-Stage Cool

TSTATBBBAC01-B

Outdoor Air Temperature Sensor

TSTATXXSEN01-B

Backplate for Non-Programmable Thermostat

TSTATXXNBP01

Backplate for Programmable Thermostat

TSTATXXPBP01

Backplate for Builder’s Thermostat

TSTATXXBBP01

Backplate for Standard Thermostat

TSTATXXSBP01

Thermostat Conversion Kit (4 to 5 wire)—10 Pack

TSTATXXCNV10

Evolution Controls

See chart.