Bryant 362AAN User Manual

Page 8

17. Use a stiff brush and vacuum cleaner to clean inside of

primary drum.

CAUTION:

Never use incendiary type cleaners (smoke

sticks) for cleaning!

WARNING:

For all heat exchanger plates that have

been removed, the gaskets MUST be replaced. Failure to

replace gaskets could lead to heat exchanger leakage,

sooting, and a hazardous condition which could lead to

bodily harm.

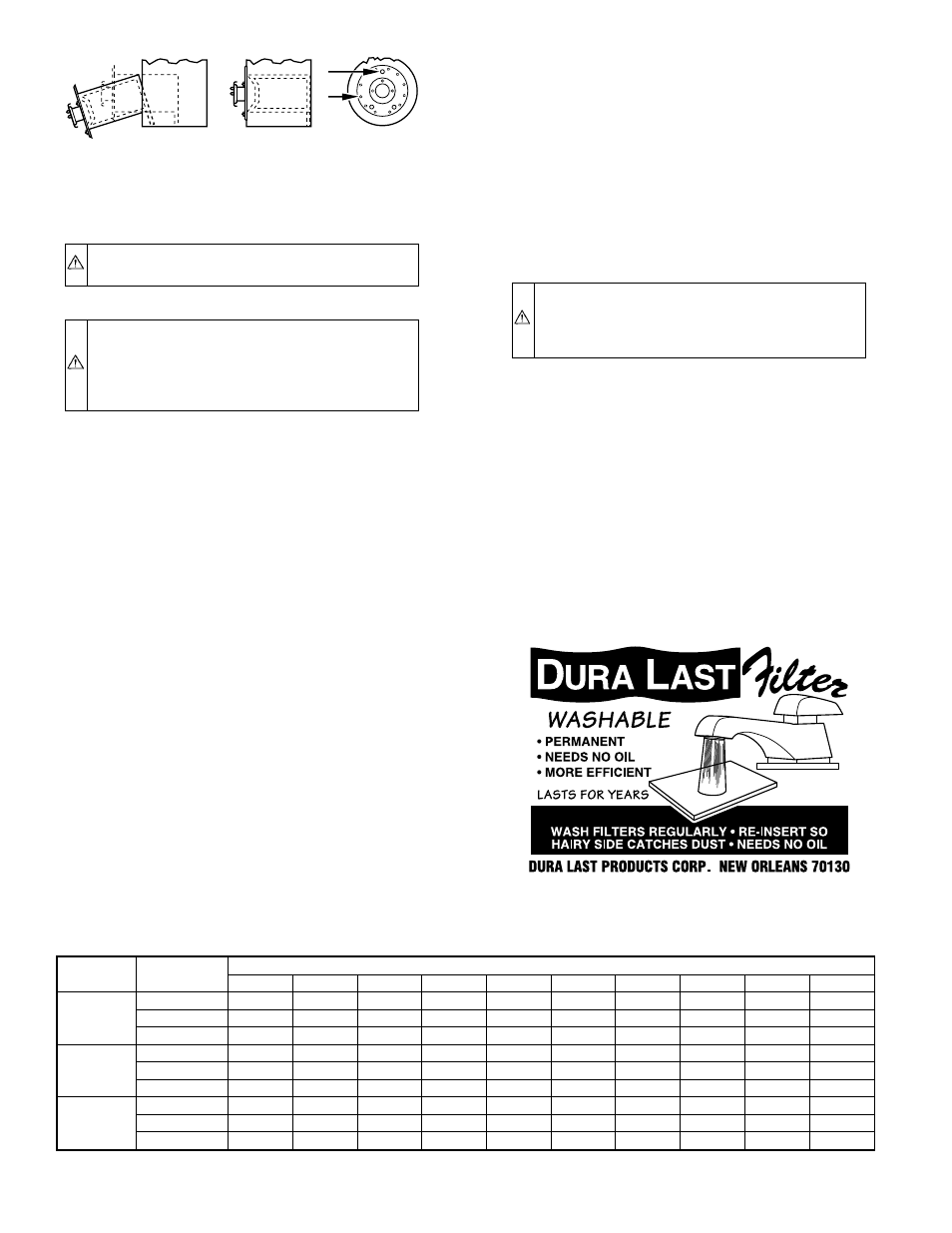

18. Before reassembly, heat exchanger and combustion cham-

ber should be inspected to determine if replacement is

required. After cleaning, place combustion chamber back

into primary drum and secure with "B" screws. Ensure that

cover plate gasket is in place before tightening screws. Care

must be taken not to damage combustion chamber. The "B"

screws should be tightened to 35-45 lb-in.

19. Tighten "A" nuts to 30 lb-in. of torque (firm, but not overly

tight).

20. Replace intermediate panel, observation tube collar, obser-

vation door, limit wiring, and oil burner.

21. Replace collector box on secondary tube flange, ensuring

proper placement of gasket. Tighten screws to 35-45 lb-in.

of torque.

22. Replace top partition, inside collar on flue pipe, top rear

panel, outside flue collar, and blower door.

23. Reconnect flue pipe and oil line(s).

24. Readjust burner for proper operation. Check limit operation

as outlined in Limit Control Check section.

IV.

BLOWER OILING AND REMOVAL

Periodic oiling of blower motor may be necessary. Check for

instructions on inside of blower access door.

If it is ever necessary to remove blower from furnace:

1. Turn off all electrical power to furnace.

2. Remove blower door.

3. Remove screws securing blower legs to blower rails

mounted on bottom panel of furnace.

4. Slide blower forward on rails toward rear of unit until motor

wire connections at terminal block on motor can easily be

reached and disconnected.

5. Disconnect motor wires at terminal block on motor.

6. Remove blower from unit.

7. Reverse items 1 through 6 to reinstall blower. Refer to

wiring diagram (Fig. 7) of these instructions or diagram

located on inside of louvered door to properly rewire unit.

V.

KEEPING FILTERS CLEAN

WARNING:

Never operate unit without a filter or with

filter access door removed. Failure to adhere to this

warning could lead to a hazardous condition which could

lead to equipment damage and bodily harm.

As a homeowner, keeping filters clean is your most important

responsibility. A dirty filter reduces efficiency of your system,

causes erratic performance of controls, and could result in damage

to motor or heating element.

1. Inspect filters at regular intervals depending upon dirt

conditions. For new homes, check filters every week for 4

consecutive weeks. In all cases, inspect filters at least every

3 to 4 weeks when system is in constant operation. Replace

or clean filter at least at beginning of each season (heating

and cooling) and thereafter as needed.

2. If a permanent filter is used, it can be cleaned with cold

water and soap.

Be sure that filter is thoroughly dry before installing back into

furnace.

→

TABLE 5—AIRFLOW DATA (CFM)

UNIT

SIZE

BLOWER

SPEED

EXTERNAL STATIC PRESSURE IN. WC

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

036105

High

1795

1735

1675

1605

1550

1485

1425

1350

1275

1220

Medium

1365

1335

1305

1275

1255

1215

1155

1105

1050

985

Low

995

965

945

925

900

870

825

775

725

670

048125

High

1905

1845

1770

1695

1630

1565

1490

1425

1325

1220

Medium

1750

1675

1620

1560

1500

1440

1370

1305

1235

1130

Low

1390

1350

1305

1260

1220

1180

1120

1060

985

880

060155

High

2025

1960

1905

1850

1800

1665

1575

1500

1415

1315

Medium

1885

1825

1760

1705

1640

1565

1500

1430

1350

1265

Low

1555

1490

1445

1410

1350

1280

1230

1155

1085

1005

NOTES: 1. Airflow values in cubic ft per minute (CFM) rounded to nearest 5 CFM.

2. Data taken without filters in place.

Fig. 4—Removing Combustion Chamber

A96398

A

B

A95103

yyy

yyy

—8—