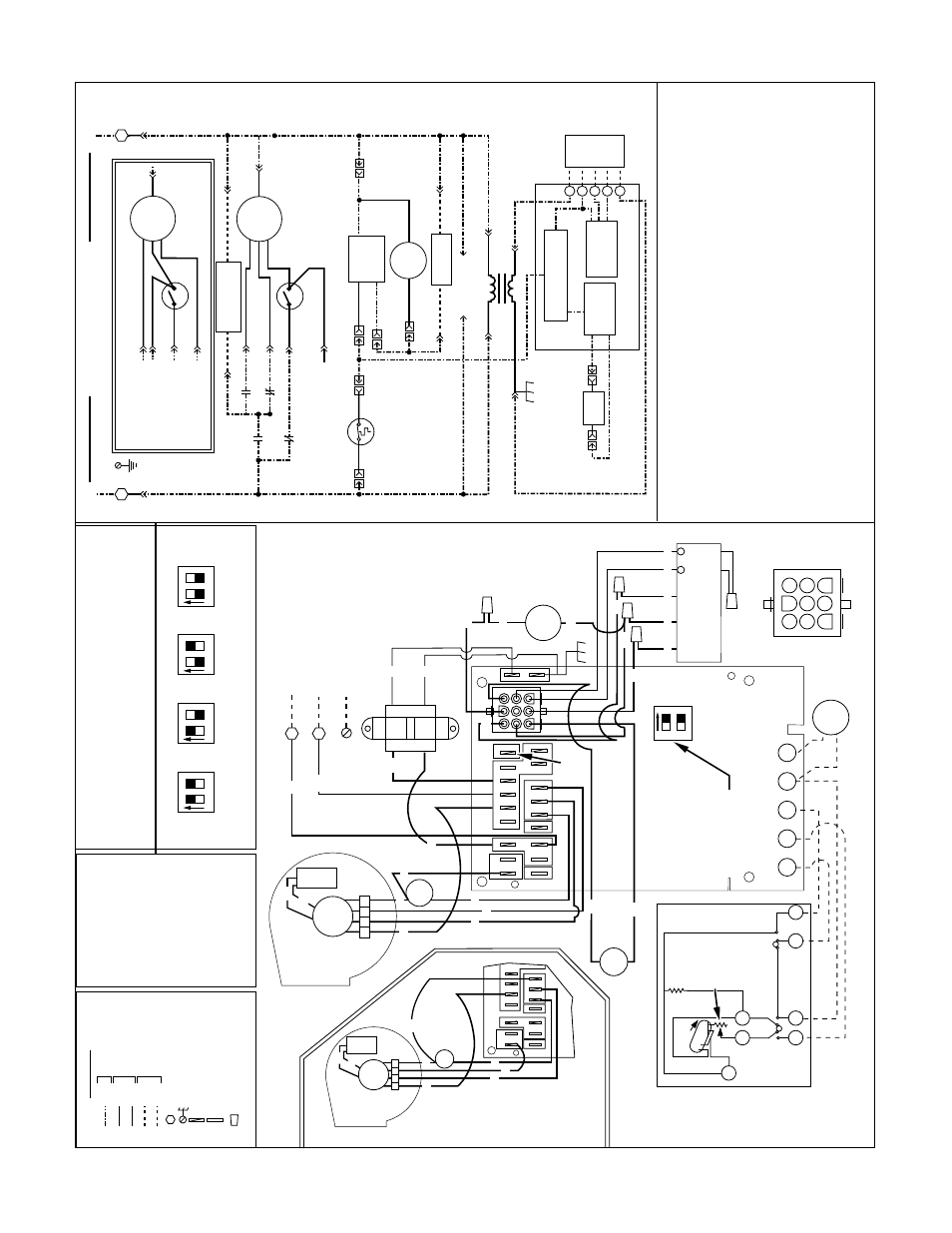

Fig. 7—wiring diagram, Legend, Delay off selection dip switch – Bryant 362AAN User Manual

Page 11

→

Fig.

7—Wiring

Diagram

A96380

INDOOR

BLOWER

MOTOR

BR

BR

CAP

T

GND

LINE V

24 V

LINE V

24 V

BK

BL

BR

GR

OR

RD

RD/BK

VI

WH

YL

F

T

CAP

AL

L

GND

BLACK

BLUE

BROWN

GREEN

ORANGE

RED

RED/BLACK STRIPE

VIOLET

WHITE

YELLOW

LOW SPEED FAN SWITCH

TRANSFORMER

STARTING CAPACITOR

AUXILARY LIMIT

LIMIT

GROUND

LEGEND

PRINTED CIRCUIT

BOARD WIRING

FACTORY WIRING

FIELD WIRING

ORANGE WIRE NUT

GROUND

= TERMINAL PROVIDED

= TERMINAL NOT PROVIDED

WIRE NUT CONNECTIONS

FACTORY WIRING

UNUSED

MOTOR

LEADS

B

U

R

N

E

R

1

1

1

4

7

23

3

X

H

U

M

C

45

6

N

7

S

2

E

A

C

C

O

N

T

C

O

O

L

H

E

A

T

H

M

L

C

F

1

2

2

1

3

5

4

6

8

7

9

1

2

12

60 Sec.

12

90 Sec.

DELAY OFF DIP SWITCH SETTINGS

12

1212

120 Sec.

12

150 Sec.

L1(H)

N3

S2

K2

K2

K1

K1

N2

N2

L1

0

L2(N)

LOW SPEED HEAT

CONNECTION

MEDIUM SPEED

HEAT CONNECTION

GND

COOL

HIGH

LOW

MED

HIGH

MED

LOW

HEAT

HEAT

CONSTANT

COOL

CN6-9

CN6-1

C

LIMIT

CN6-6

CN6-3

S1

N1

X

N4

S3

CN6-2

CN6-7

CN6-8

BURNER

MOTOR

PRIMARY

ACCESSORY

120VAC

24VAC

LIMIT SENSE

OIL ELECTRONIC FAN TIMER

GND

TRANSFORMER

CN6-4

CONSTANT

LOW SPEED

FAN SWITCH

LOW SPEED

FAN SWITCH

UNUSED MOTOR LEAD

L2

UNUSED MOTOR LEAD

CIRCULATION BLOWER

CIRCULATION

BLOWER

CIRCULATION

BLOWER

K1, K2

CONTROL

K3

TSTAT

R

W

Y

G

C

T1 T2

PRIMARY

115 VAC 1

ø

60HZ POWER SUPPLY

(FUSED DISCONNECT ON HOT LEG)

(1) MAKE FIELD POWER SUPPLY CONNECTIONS TO BLACK AND WHITE WIRES CAPPED

WITH ORANGE WIRE NUTS.

(2) WARNING--- UNIT MUST BE GROUNDED. WIRING MUST CONFORM TO N.E.C. AND

LOCAL CODES. IN CANADA WIRING MUST CONFORM TO CURRENT CSA 22.1 CANADIAN

ELECTRICAL CODE PART 1 AND/OR LOCAL CODES.

(3) IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE FURNACE MUST BE REPLACED,

IT MUST BE REPLACED WITH WIRING MATERIAL HAVING A TEMPERATURE RATING OF

AT LEAST 105

°

C AND BE A MINIMUM OF 16 GA. AWG COPPER STRAND WIRE. USE

COPPER WIRE ONLY FOR FIELD WIRING.

(4) CONNECT REQUIRED MOTOR LEAD TO HEAT TERMINAL ON CIRCUIT BOARD TO DELIVER

A TEMPERATURE RISE WITHIN THE RANGE SPECIFIED ON THE RATING PLATE.

(5) SET THE HEAT ANTICIPATOR ON THE THERMOSTAT AT .2 AMPS.

(6) FOR ELECTRICAL LOAD AMPERES, BRANCH CIRCUIT AMPACITY AND MAXIMUM FUSE

SIZE SEE FURNACE MODEL LABEL.

(7) HUM TERMINAL IS 115V.

H

M

L

C

INDOOR

BLOWER

MOTOR

LOW SPEED HEAT

CONNECTION DETAIL

BR

BR

CAP

UNUSED

MOTOR

LEADS

B

U

R

N

E

R

1

123

34

S

2

E

A

C

C

O

N

T

C

O

O

L

H

E

A

T

F

1 2 3 4

RD

RD

RD/BK

WH

BK

BL

YL

RD

RD

L

FIXED COOL

ANTICIPATOR

ADJUSTABLE

HEATING

ANTICIPATOR

TEMP

FALL

TYPICAL THERMOSTAT

COOL

OFF

FAN

AUTO

ON

HEAT

W

R1

W1

Y1

GW

R

Y

C

I

YR

G

DELAY OFF

SELECTION

DIP SWITCH

DELAY OFF

SELECT

CN6

VI

BK

BURNER

MOTOR

WH

WH

CN6

WH

OR

YL

BL

BK

L1

L2

ORANGE

FLAME DETECT

ENLARGED TOP VIEW

CAD CELL

(BLACK)

(WHITE)

INTERUPTED OIL PRIMARY CONTROL

T1

T2

BK

OR

COOLING

CONTACTOR

(IN AIR

CONDITIONER,

IF USED)

WH

BK

L1 (H)

L2 (N)

GND

BL

YL

WH

- - -

- - -

- - -

- - -

- - -

- - -

1 2 3 4

BK

WH

RD

RD

YL

BL

Honeywell

NOTES:

POWER SUPPLY

115 VAC /1Ø 60 HZ

(FUSED DISCONNECT ON HOT LEG)

MEDIUM SPEED

HEAT CONNECTION

ST9103

N5

ELECTRONIC AIR

CLEANER

(OPTIONAL)

EAC

HUM

N6

HUMIDIFIER (OPTIONAL)

SEE

NOTE 7

FACTORY SET

HEATING SPEED

105-- MED (M)

125-- MED (M)

155-- HIGH (H)

—11—