Bryant 362AAN User Manual

Page 7

The procedure for nozzle installation and/or replacement is out-

lined in oil burner instruction manual which came with furnace.

For ease of maintenance, the oiling procedure for burner motor, as

outlined in burner manual, should be performed at this time.

After replacement of nozzle, burner should be adjusted in accor-

dance with Combustion Check section of this instruction.

III.

HEAT EXCHANGER AND FLUE PIPE

Ordinarily, it is not necessary to clean heat exchanger or flue pipe

every year, but it is necessary to have your service technician

check unit before each heating season to determine whether

cleaning or replacement of parts is required.

A.

Cleaning Secondary Heat Exchanger Tubes and

Flue Pipe Only

If cleaning of only the secondary heat exchanger tubes and flue

pipe is necessary, the following steps should be performed:

1. Turn off all oil and electrical supplies upstream of furnace.

CAUTION:

If furnace has been in operation, some

surfaces may be hot. Allow time for unit to cool down.

2. Disconnect flue pipe.

3. For access to cleanout ports, remove blower door and filter.

The 2 cleanout ports are located in blower compartment.

They protrude through the partition and are located on the

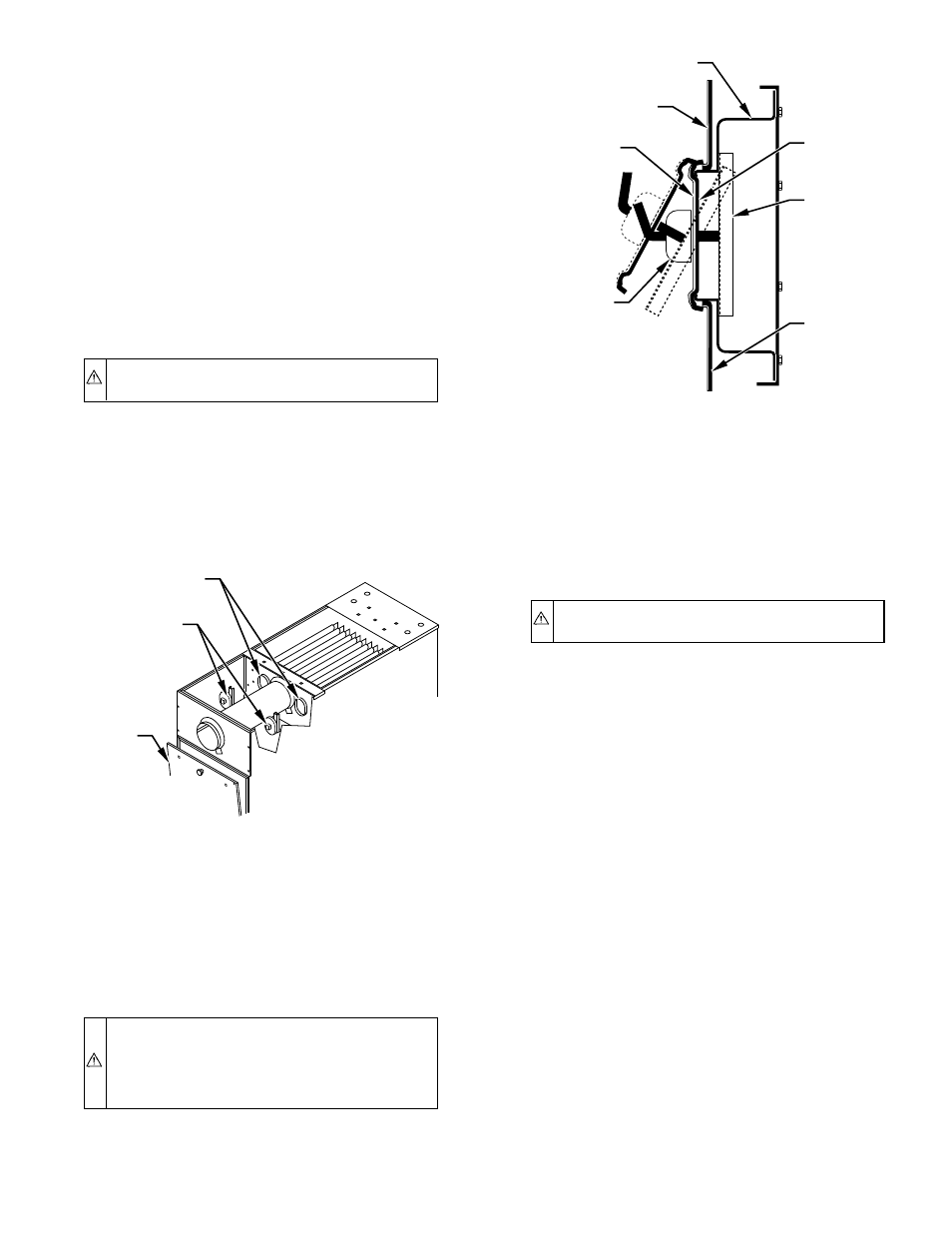

left and right of flue pipe. (See Fig. 2.)

4. Unscrew wing clamp nuts and remove cleanout port covers.

This allows access to tubes. (See Fig. 2.)

5. Clean secondary tubes and flue pipe with a stiff brush and

vacuum cleaner.

6. Before reinstalling cleanout port covers, the gasket on each

cover MUST be replaced. Use cleanout port gasket kit Part

No. 20196201.

7. Reinstall covers and tighten in place making sure that

covers are properly seated over ports and gasket has sealed

opening. (See Fig. 3.)

WARNING:

Failure to replace cleanout port cover gas-

kets, failure to properly seat covers over ports, and/or

failure to securely tighten wing nuts could lead to flue gas

leakage. This could lead to furnace damage, oil fumes,

sooting, and severe bodily harm.

8. Reconnect flue pipe.

9. Reinstall filter and blower door.

10. Turn on power to unit and readjust burner for proper

operation. Inspect cleanout ports and flue connection to

make sure there are no leaks.

B.

Cleaning Both Primary and Secondary Heat

Exchangers

If a more thorough cleaning is required (both primary and

secondary heat exchanger sections), the following steps should be

performed:

1. Turn off all oil and electrical supplies upstream of furnace.

CAUTION:

If furnace has been in operation, some

surfaces may be hot. Allow time for unit to cool down.

2. Remove blower door.

3. Disconnect flue pipe.

4. Remove outside flue collar.

5. Remove top rear panel.

NOTE:

Blower removal as described in Blower Oiling and

Removal section may be desired for easier access when cleaning

with duct work attached.

6. Remove inside collar on flue pipe.

7. Remove top partition.

8. Place field-fabricated cardboard on metal tray beneath

collector box to prevent debris from entering blower com-

partment.

9. Remove flue collector box from secondary heat exchanger

tube flange. This exposes inside surfaces of secondary tubes

of heat exchanger.

10. Clean secondary tubes and flue pipe with a stiff brush and

vacuum cleaner.

11. Remove louvered door.

12. Disconnect limit control wires.

13. Disconnect oil line and remove oil burner from furnace.

14. Remove observation door and collar on observation tube.

15. Remove intermediate panel. Care must be taken not to bend

or damage limit control.

16. Loosen to hand tightness the 3 nuts labeled "A" in Fig. 4.

Remove screws labeled "B" in Fig. 4. Slide combustion

chamber forward out of heat exchanger. Be careful not to

bump combustion chamber as it becomes brittle after

having been fired.

Fig. 2—Removing Cleanout Port Covers

A96310

CLEANOUT

PORTS

CLEANOUT

PORT COVER

& CLAMP

ASSEMBLY

BLOWER

DOOR

Fig. 3—Reinstalling Cleanout Port Covers

A96311

FLUE BOX

PARTITION

PANEL

CLEANOUT

PORT COVER

WING

CLAMP

NUT

CLEANOUT

COVER

GASKET

CLEANOUT

COVER

CLAMP

BRACKET

INSULATION

—7—

→