Burnham HF SERIES User Manual

Page 19

19

SOLID stream without air bubbles for approxi-

mately 10 seconds.

3. Close vent fitting and burner flame should start

immediately.

4. If the burner does not start immediately, check the

manual overload switch on the motor, if so

equipped, and the safety switch on the burner

primary control.

K.

ADJUST OIL PRESSURE

1. Locate oil pressure adjusting screw and turn

screw until Pressure Gauge reads the correct

pump pressure required for the specific boiler.

Refer to Table 4 .

2. DO NOT REMOVE PRESSURE GAUGE until

later.

L.

OTHER ADJUSTMENTS

1. ADJUST THE AIR BAND AND/OR AIR SHUT-

TER.

Beckett Burners:

a. Adjust air supply by loosening lock screws and

moving the air shutter and if necessary the air

band. Refer to Table 4 preliminary settings.

2. ADJUST DRAFT REGULATOR for a draft of

-.02” (water gauge) over the fire after chimney has

reached operating temperature and while burner is

running.

3. READJUST AIR BANDS on burner for a light

orange colored flame while draft over the fire is

-.02” w.c. Use a smoke test and adjust air for

minimum smoke (not to exceed #1) with a mini-

mum of excess air. Make final check using suitable

instrumentation to obtain a CO

2

of 11.5 to 12.5%

with draft of -.02” w.c. in fire box. These settings

will assure a safe and efficient operating condition.

If the flame appears stringy instead of a solid flame,

try another nozzle of the same type. Flame should

be solid and compact. After all adjustments have

been made, recheck for a draft of -.02” w.c. over the

fire.

4. TURN “OFF” BURNER and remove pressure

gauge. Install gauge port plug and tighten. Start

burner again.

M.

FLAME FAILURE

The HF boiler controls operate the burner automati-

cally. If for unknown reasons the burner ceases to fire

and the rest button on the primary control has tripped,

the burner has experienced ignition failure. Before

pressing the rest button, call your serviceman immedi-

ately.

N.

CHECK FOR CLEAN CUT OFF OF BURNER

1. AIR IN THE OIL LINE between fuel unit and

nozzle will compress when burner is on and will

expand when burner stops, causing oil to squirt

from nozzle at low pressure as burner slows down

and causing nozzle to drip after burner stops.

Usually cycling the burner operation about 5 to 10

times will rid oil line of this air.

2. IF NOZZLE CONTINUES TO DRIP, repeat step

N.1. If this does not stop the dripping, remove cut

off valve and seat, and wipe both with a clean cloth

until clean. Then replace and readjust oil pressure.

If dripping or after burn persist replace fuel pump.

O.

HINTS ON COMBUSTION

a. NOZZLES— Although the nozzle is a relatively

inexpensive device, its function is critical to the

successful operation of the oil burner. The

selection of the nozzle supplied with the HF

boiler is the result of extensive testing to obtain

the best flame shape and efficient combustion.

Other brands of the same spray angle and spray

pattern may be used but may not perform at the

expected level of CO

2

and smoke. Nozzles are

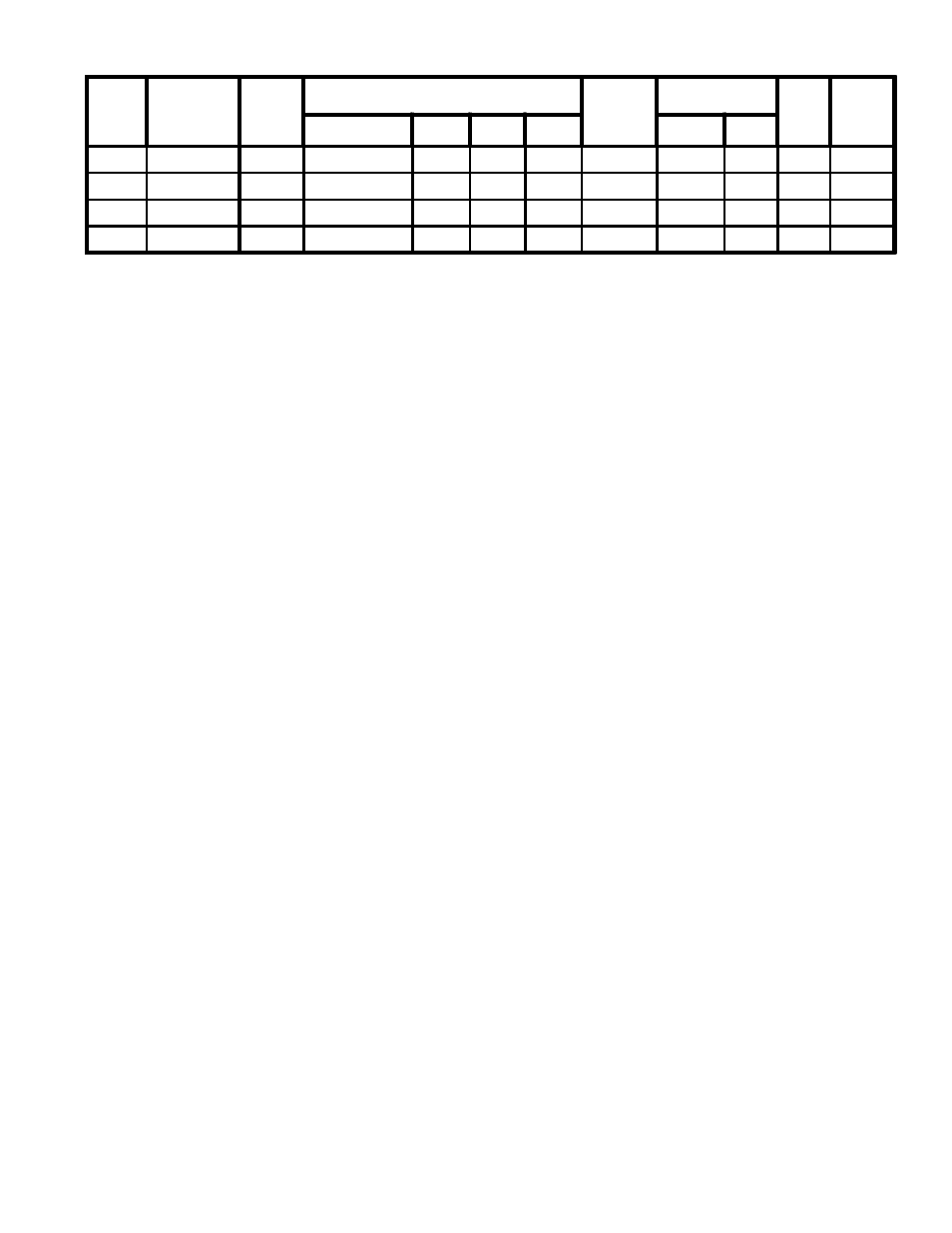

Table 4: Beckett AFG

Boiler

Model

No.

Firi ng

Rate

(GPH)

Burner

Nozzle Specificati ons

Static

Plate

Air Setti ngs

Head

Head

Setti ng

M anufacturer

Size

Angle

Type

Shutter

Band

HF98

.85

A FG

HA GO

.75

45°

B

3-3 /8"U

8

0

L1

0

HF122

1.10

A FG

HA GO

.90

45°

B

3-3 /8"U

10

2

L1

0

HF147

1.25

A FG

HA GO

1.0

45°

B

2-3 /4"U

10

0

V1

0

HF173

1.50

A FG

HA GO

1.25

45°

B

2-3 /4"U

10

2

V1

2