Notice – Burnham HF SERIES User Manual

Page 16

16

J

.

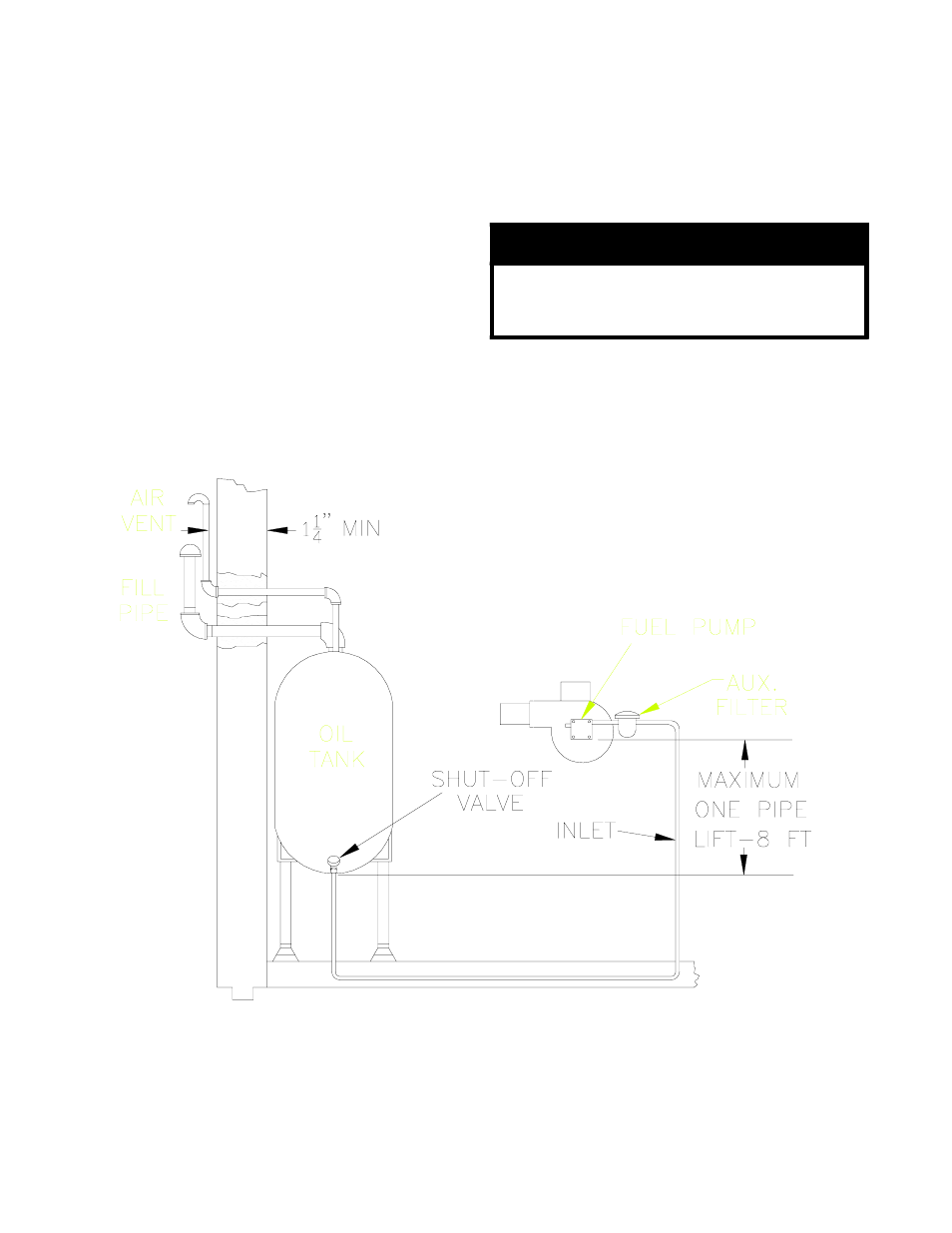

Oil Piping

1. Use flexible oil line(s) so that burner can be

removed without disconnecting the oil supply.

2. A supply line fuel oil filter is recommended as a

minimum for all firing rates but a pleated paper

fuel oil filter is recommended for the lowest firing

rate application to prevent nozzle fouling.

3. Use Flared fittings only. Do not use compression

fittings.

4. Use of a high efficiency micron filter (Garber or

equivalent) in addition to conventional filter is

highly recommended.

Figure 12: Single-Pipe Installation

NOTICE

Oil piping must be absolutely airtight or

leaks or loss of prime may result. Bleed line

and fuel unit completely.

K

. Single-pipe Oil Lines

1. Standard burners are provided with single-stage

3450 rpm fuel units with the bypass plug removed

for single-pipe installations.

2. The single-stage fuel unit may be installed single-

pipe with gravity feed or lift. Maximum allowable

lift is 8 feet. See Figure 12.

- 81433101R16-1/10 (40 pages)

- Gas-Fired (4 pages)

- Independence IN8 (1 page)

- Independence IN9 (92 pages)

- ALP105 (100 pages)

- 53A (22 pages)

- CHG150 (72 pages)

- Series 2B (52 pages)

- LEDV-3 (1 page)

- ALP399 (3 pages)

- MST513 (4 pages)

- SL AL119SL (1 page)

- PVG (64 pages)

- Independence PV (6 pages)

- V9A (64 pages)

- SERIES 3 1099-01R1-/10 (8 pages)

- RSA (52 pages)

- E4 (8 pages)

- SCG 1100-H4 (96 pages)

- SERIES 2 (6 pages)

- MEGASTEAM MST396 (68 pages)

- V7 SERIES (47 pages)

- V9 (4 pages)

- LE L7248 (28 pages)

- LEDV SERIES (36 pages)

- MST396 (64 pages)

- ES2 (52 pages)

- ALP080 (7 pages)

- Minuteman II (6 pages)

- PVG & SCG (4 pages)

- V8 Series (100 pages)

- FCM120 (80 pages)

- Carefree DOE (3 pages)

- 20_PV_I (32 pages)

- BOILERS (48 pages)

- MPO Series (4 pages)

- V8H Series (2 pages)

- 8H (92 pages)

- SM-6 (28 pages)

- SCG (92 pages)

- CHG (4 pages)

- ALPINE (8 pages)

- MULTI-PASS (108 pages)

- C4 SERIES (2 pages)