Bryant 564B User Manual

Page 6

TABLE 3—MINIMUM AIRFLOW FOR SAFE ELECTRIC

HEATER

OPERATION (CFM)

SIZE

024

030

036

042

048

060

Cfm

600

750

900

1050

1200

1500

CAUTION: UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit compo-

nent damage. Operation of unit on improper line voltage

constitutes abuse and may cause unit damage that could

affect warranty.

B.

ROUTING POWER LEADS INTO UNIT

Use only copper wire between disconnect and unit. The high-

voltage leads should be in a conduit until they enter the unit;

conduit termination at the unit must be watertight. Run the

high-voltage leads through the hole on the control box side of the

unit (see Fig. 7 for location). When the leads are inside the unit,

run leads to the control box (Fig. 8). For single-phase units,

connect leads to the black and yellow wires (see Fig. 9).

C.

CONNECTING GROUND LEAD TO UNIT GROUND

Refer to Fig. 8 and 9. Connect the ground lead to the chassis using

the unit ground in the control box.

D.

ROUTING CONTROL POWER WIRES

Form a drip-loop with the thermostat leads before routing them

into the unit. Route the thermostat leads through grommeted hole

provided in unit into unit control box (See Fig. 7). Connect

thermostat leads and unit power leads as shown in Fig. 9, 10A &

10B.

Route thermostat wires through grommet providing a drip-loop at

the panel. Connect low-voltage leads to the thermostat as shown in

Fig. 10A & 10B.

The unit transformer supplies 24-v power for complete system

including accessory electrical heater. Transformer is factory wired

for 230-v operation.

E.

ACCESSORY ELECTRIC HEAT WIRING

Refer to accessory electric heat installation instructions for infor-

mation on installing accessory electric heat. Accessory electric

heat wiring is shown in Fig. 11A, 11B, & 11C.

PRE-START-UP

WARNING: FIRE,

EXPLOSION,

ELECTRICAL

SHOCK HAZARD

Failure to observe the following warnings could result in

serious injury, death and/or property damage:

1. Follow recognized safety practices and wear protective

goggles when checking or servicing refrigerant system.

2. Do not operate compressor or provide any electric

power to unit unless compressor terminal cover is in

place and secured.

3. Do not remove compressor terminal cover until all

electrical sources are disconnected and lockout tag is

installed.

4. Relieve all pressure from both high- and low-pressure

sides of the system before touching or disturbing

anything inside terminal box if refrigerant leak is

suspected around compressor terminals. Use accepted

methods to recover refrigerant.

5. Never attempt to repair soldered connection while

refrigerant system is under pressure.

6. Do not use torch to remove any component. System

contains oil and refrigerant under pressure. To remove

a component, wear protective goggles and proceed as

follows:

a. Shut off electrical power to unit and install lockout

tag.

b. Relieve all refrigerant from system using both high-

and low-pressure ports. Use accepted methods to

recover refrigerant.

c. Cut component connecting tubing with tubing cutter

and remove component from unit.

d. Carefully unsweat remaining tubing stubs when

necessary. Oil can ignite when exposed to torch

flame.

Use the Start-Up Checklist supplied at the end of this book and

proceed as follows to inspect and prepare the unit for initial

start-up:

1. Remove all access panels.

2. Read and follow instructions on all DANGER, WARNING,

CAUTION, and INFORMATION labels attached to, or

shipped with unit.

Make the following inspections:

a. Inspect for shipping and handling damages such as

broken lines, loose parts, disconnected wires, etc.

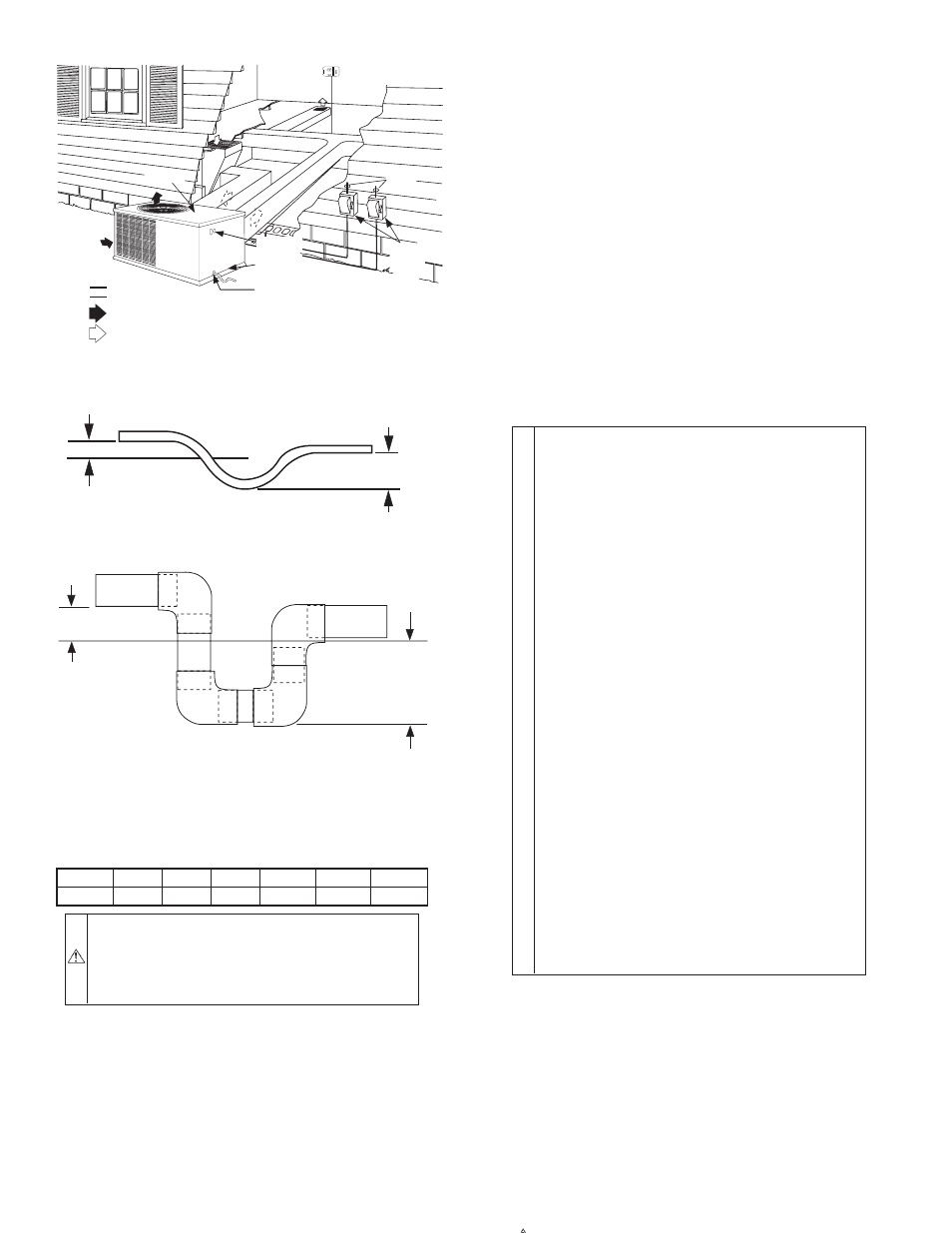

Fig. 4—Typical installation

C00008

C00008

TOP COVER

INDOOR

THERMOSTAT

DISCONNECT

PER NEC*

(UNIT AND

ELECTRIC

HEATER)

FROM

POWER

SOURCE

RETURN

AIR

POWER AND

LOW-VOLTAGE

ENTRY

COMPOSITE

RUST-PROOF

BASEPAN

CONDENSATE

DRAIN

CONNECTION

*Separate disconnect per NEC

(National Electrical Code) required

for electric heater when single-

point conection is not used.

Power Wiring

Control Wiring

Condenser Airflow

Evaporator Airflow

Fig. 5—Condensate Trap (Using Tubing)

C99013

1” (25mm) MIN.

2” (50mm) MIN.

TRAP

OUTLET

Fig. 6—PVC Condensate Trap

C00009

TRAP

OUTLET

2" min.

1" min.

—6—