Bryant 564B User Manual

Page 14

D.

HEATING OPERATION (SIZES 024-042)

With a call for heating (W2), the auziliary or electric heat

energizes along with the indoor blower. In case of staged heating,

W3 is energized if the demand is not met. The highest airflow

selected is run while the electric heat is in operation. When heating

demand is met, W3 and W2 sequentially de-energize shutting the

indoor fan and the electric heater.

E.

HEATING OPERATION (SIZES 048 AND 060)

With a call for heating (W2), the auxiliary electric heater is

energized along with the indoor blower. If the demand is not met,

W3 is energized in case of staged heating. When heating demand

is satisfied, W3 and W2 sequentially de-energize along with the

indoor fan blower.

F.

CONTINUOUS FAN

With the continuous Indoor fan option selected on the thermostat,

G is continuously energized. In case of 024-042 units, the selected

airflow setting is provided. In case of 048 and 060 units, the

system runs low stage (Y1) airflow for continuous fan operation.

G.

DEFROST

Defrost board (DB) is a time and temperature control, which

includes a field-selectable time period between checks for defrost

(30, 60, 90 and 120 minutes). The time period is factory-set at 60

minutes and should only be adjusted by a trained service person.

Electronic timer and defrost cycle start only when contactor is

energized and defrost thermostat (DFT) is closed.

Defrost mode is identical to Cooling mode. The outdoor fan motor

stops because of “OF1” and “OF2” contacts opening on the defrost

board, a bank of optional electric heat turns on to warm air

supplying the conditioned space.

H.

ELECTRIC RESISTANCE HEATING

If accessory electric heaters are installed, on a call for “Emergency

Heat” the thermostat energizes W which energises the heater relay

and in turn energizes the electric heaters. The IFR is energized

which starts the indoor-fan motor. If the heaters are staged, W2 is

energized when the second stage of heating is required. When the

need for heating is satisfied, the heater and IFM are deenergized.

MAINTENANCE

To ensure continuing high performance, and to reduce the possi-

bility of premature equipment failure, periodic maintenance must

be performed on this equipment. This cooling unit should be

inspected at least once each year by a qualified service person. To

troubleshoot cooling of units, refer to Troubleshooting chart in

back of book.

NOTE TO EQUIPMENT OWNER: Consult your local dealer

about the availability of a maintenance contract.

WARNING: FIRE,

EXPLOSION,

ELECTRICAL

SHOCK HAZARD

Failure to follow this warning could result in personal

injury, death or property damage.

The ability to properly perform maintenance on this

equipment requires certain expertise, mechanical skills,

tools and equipment. If you do not possess these, do not

attempt to perform any maintenance on this equipment,

other than those procedures recommended in the User’s

Manual.

The minimum maintenance requirements for this equipment are as

follows:

1. Inspect air filter(s) each month. Clean or replace when

necessary.

2. Inspect indoor coil, outdoor coil, drain pan, and condensate

drain each cooling and heating season for cleanliness. Clean

when necessary.

3. Inspect blower motor and wheel for cleanliness each

cooling and heating season. Clean when necessary. For first

heating season, inspect blower wheel bimonthly to deter-

mine proper cleaning frequency.

4. Check electrical connections for tightness and controls for

proper operation each cooling season. Service when neces-

sary.

5. Check the drain channel in the top cover periodically for

blockage (leaves, insects). Clean as needed.

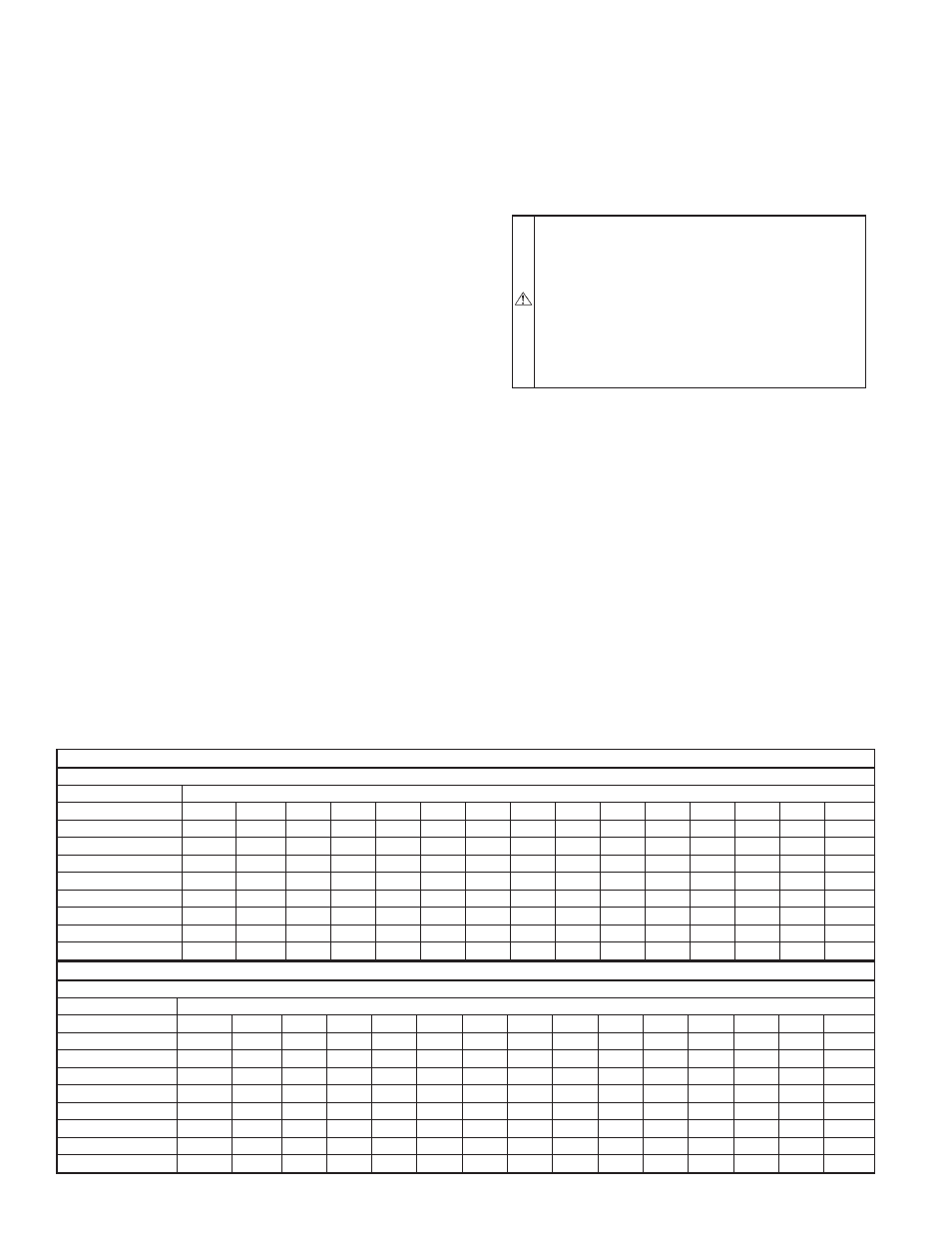

TABLE 8—COOLING CHARGING CHART

SUCTION LINE TEMPERATURE (°F)

Suction Line Pressure (PSIG)

OD Temp. (°F)

52

54

56

59

61

64

67

70

73

76

79

82

85

89

92

45

51

55

60

64

69

—

—

—

—

—

—

—

—

—

—

55

—

—

53

57

62

66

70

—

—

—

—

—

—

—

—

65

—

—

—

—

53

57

62

66

71

75

—

—

—

—

—

75

—

—

—

—

—

—

—

56

61

66

71

76

—

—

—

85

—

—

—

—

—

—

—

—

53

58

63

67

72

—

—

95

—

—

—

—

—

—

—

—

—

50

54

58

62

66

—

105

—

—

—

—

—

—

—

—

—

—

50

53

57

60

64

115

—

—

—

—

—

—

—

—

—

—

49

52

55

58

61

125

—

—

—

—

—

—

—

—

—

—

—

50

53

56

59

SUCTION LINE TEMPERATURE (°C)

Suction Line Pressure (kPa)

OD Temp. (°C)

361

370

387

405

423

442

462

482

502

523

544

566

589

612

636

7

11

13

15

18

21

—

—

—

—

—

—

—

—

—

—

13

—

—

12

14

16

19

21

—

—

—

—

—

—

—

—

18

—

—

—

—

12

14

17

19

21

24

—

—

—

—

—

24

—

—

—

—

—

—

—

13

16

19

22

24

—

—

—

29

—

—

—

—

—

—

—

—

12

14

17

20

22

—

—

35

—

—

—

—

—

—

—

—

—

10

12

14

17

19

—

41

—

—

—

—

—

—

—

—

—

—

10

12

14

16

18

46

—

—

—

—

—

—

—

—

—

—

9

11

13

14

16

52

—

—

—

—

—

—

—

—

—

—

—

10

11

13

15

—14—