Burnham V8 Series User Manual

Page 69

69

Carlin Elite EZ Burners

a. Carlin EZ-1HP and EZ-2HP burners use a head

positioning bar to fi x the head setting based

on nozzle size. To adjust this setting, bar must

be changed to the next larger or smaller bar

available. Refer to Section II, Paragraph D for

details.

4. READJUST THE TURBULATOR SETTING only

if necessary.

Riello

Burners

a. V82 through V89

Move the turbulator setting forward or back one

position at a time to optimize the smoke and

CO2 readings.

b. Turn “OFF” burner and remove Riello

Combination Pressure Gauge and Bleeder Valve

Assembly. Install pressure port/bleeder plug and

tighten. Start burner again.

5. TURN “OFF” BURNER and remove pressure

gauge. Install gauge port/bleeder plug and tighten.

Start burner again.

G

N

I

N

R

A

W

s

g

n

i

t

t

i

f

e

n

i

l

l

i

o

y

n

a

e

v

o

m

e

r

r

o

n

e

s

o

o

l

t

o

n

o

D

.

g

n

i

t

a

r

e

p

o

s

i

r

e

n

r

u

b

e

l

i

h

w

6. FLAME FAILURE

The V8 boiler controls operate the burner

automatically. If for unknown reasons the burner

ceases to fi re and the reset button on the primary

control has tripped, the burner has experienced

ignition failure.

G

N

I

N

R

A

W

n

e

h

w

r

e

n

r

u

b

e

h

t

t

r

a

t

s

o

t

t

p

m

e

t

t

a

t

o

n

o

D

t

i

n

u

e

h

t

n

e

h

w

,

d

e

t

a

l

u

m

u

c

c

a

s

a

h

l

i

o

s

s

e

c

x

e

n

o

i

t

s

u

b

m

o

c

e

h

t

n

e

h

w

r

o

,

r

o

p

a

v

f

o

l

l

u

f

s

i

.

t

o

h

y

r

e

v

s

i

r

e

b

m

a

h

c

H. CHECK FOR CLEAN CUT OFF OF

BURNER.

1. AIR IN THE OIL LINE between fuel unit and

nozzle will compress when burner is on and will

expand when burner stops, causing oil to squirt from

nozzle at low pressure as burner slows down and

causing nozzle to drip after burner stops. Usually

cycling the burner operation about 5 to 10 times will

rid oil line of this air.

2. IF NOZZLE CONTINUES TO DRIP, repeat

Paragraph I, No. 1. If this does not stop the

dripping, remove cut-off valve and seat, and wipe

both with a clean cloth until clean, then replace

and readjust oil pressure. If dripping or after burn

persist replace fuel pump.

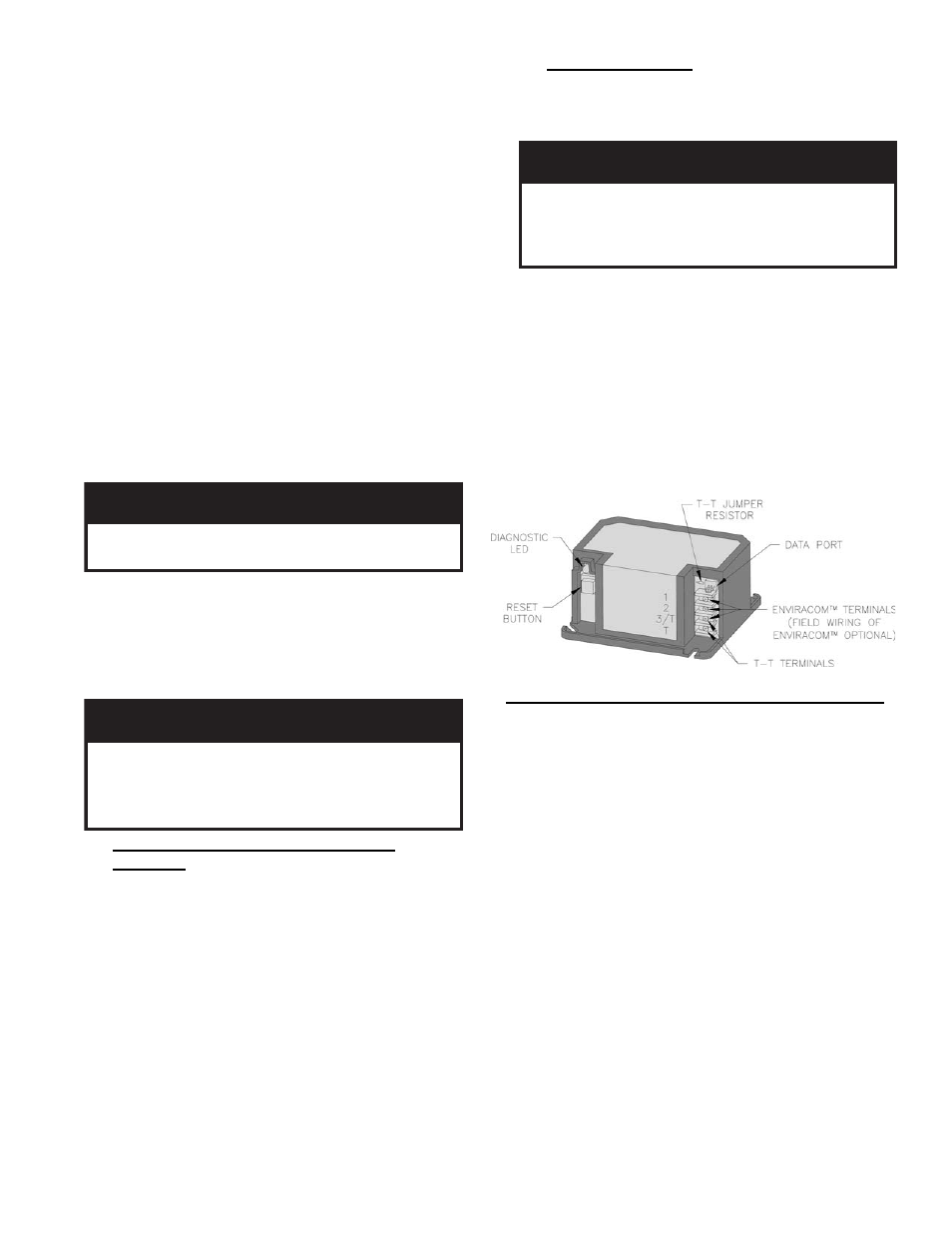

Figure 28: R7184 Terminals, LED and Reset Button

I.

TEST CONTROLS.

1. Check thermostat operation. Raise and lower

thermostat setting as required to start and stop

burner.

G

N

I

N

R

A

W

d

e

r

e

d

i

s

n

o

c

s

i

r

e

l

i

o

b

e

h

t

f

o

n

o

i

t

a

l

l

a

t

s

n

i

e

r

o

f

e

B

s

l

o

r

t

n

o

c

r

e

l

i

o

b

l

l

a

f

o

n

o

i

t

a

r

e

p

o

e

h

t

,

e

t

e

l

p

m

o

c

y

r

a

m

i

r

p

e

h

t

y

l

r

a

l

u

c

i

t

r

a

p

,

d

e

k

c

e

h

c

e

b

t

s

u

m

.

l

o

r

t

n

o

c

t

i

m

i

l

h

g

i

h

d

n

a

l

o

r

t

n

o

c

2. VERIFY PRIMARY CONTROL FEATURES

using procedures outlined in Instructions furnished

with control or instructions as follows:

a. FEATURES

AND CONTROLS

i.

The R7184 is a microprocessor-based

control. The indicator light provides

diagnostic information for lockout, recycling

and patented cad cell status. There is a

manual reset button to exit the Lockout

Mode and enter the Idle Mode (see Figure

28).

ii. Pump Priming Cycle: To facilitate purging

air from the oil lines and fi lters, the R7184

can be placed in a purge routine by pressing

and releasing the reset button during the

safety check, delayed valve-on, ignition or

carry-over periods.

iii. Limited

Recycle: This feature limits the

number of recycle trials (for each call

for heat) to a maximum of three trials. If

the fl ame is lost three times and does not

successfully satisfy a call for heat, the

R7184 locks out.

iv. Limited Reset (Restricted Mode): In order

to limit the accumulation of unburned oil in

the combustion area, the control can only be

reset three times. The reset count returns to

zero each time a call for heat is successfully

completed.

•

To reset from Restricted Mode: Press and

hold the reset button for 30 seconds.

When

the

LED

fl ashes twice, the device

has

reset.