Vollrath F111 User Manual

Page 14

Owner’s Manual #513532-5 Rev.1

8

E111I/F111I Model Machines

2.

MACHINE DAMAGE – Strong acids will attack

metal and rubber causing premature wear of

parts. The use of a delimer needs to be closely

monitored to avoid damage to machine surfaces

and parts.

With proper daily use of STERA-SHEEN or its equivalent,

there is no need for the use of a DELIMER.

DO NOT USE BLEACH

•

BLEACH HAS ABSOLUTELY NO CLEANING

PROPERTIES.

•

BLEACH IS CORROSIVE. It will damage

components of the machine causing premature

wear and metal corrosion.

GENERAL PURPOSE CLEANERS

General purpose cleaners do not have the ability to re-

move milkstone. Milkstone will become a problem if not

remedied with additional products and procedures.

THE USE OF CHLORINE TEST STRIPS

“Test strips” are used to determine concentrations of

active chlorine in sanitizing solutions. To use the strips,

tear off a small portion and submerge it into the sanitizing

solution. Then, compare the color change to the color key

on the side of the test strip dispenser to determine the

approximate chlorine concentration.

The ideal concentration of chlorine needs to be 100 ppm

(as stated by the FDA).

NOTE

Follow the directions on the container for proper

concentration.

Two main factors contribute to falling chlorine concentra-

tions in a sanitizing solution.

1.

PRODUCT USE – As the chlorine in the solution

is being used, chlorine concentrations fall.

2.

TIME – As time passes, small amounts of chlorine

“evaporate” from the solution. (That is why you

can smell it.)

Sanitizing solutions should not be allowed to fall below

100 ppm chlorine. New solutions should be mixed once

old solutions become ineffective.

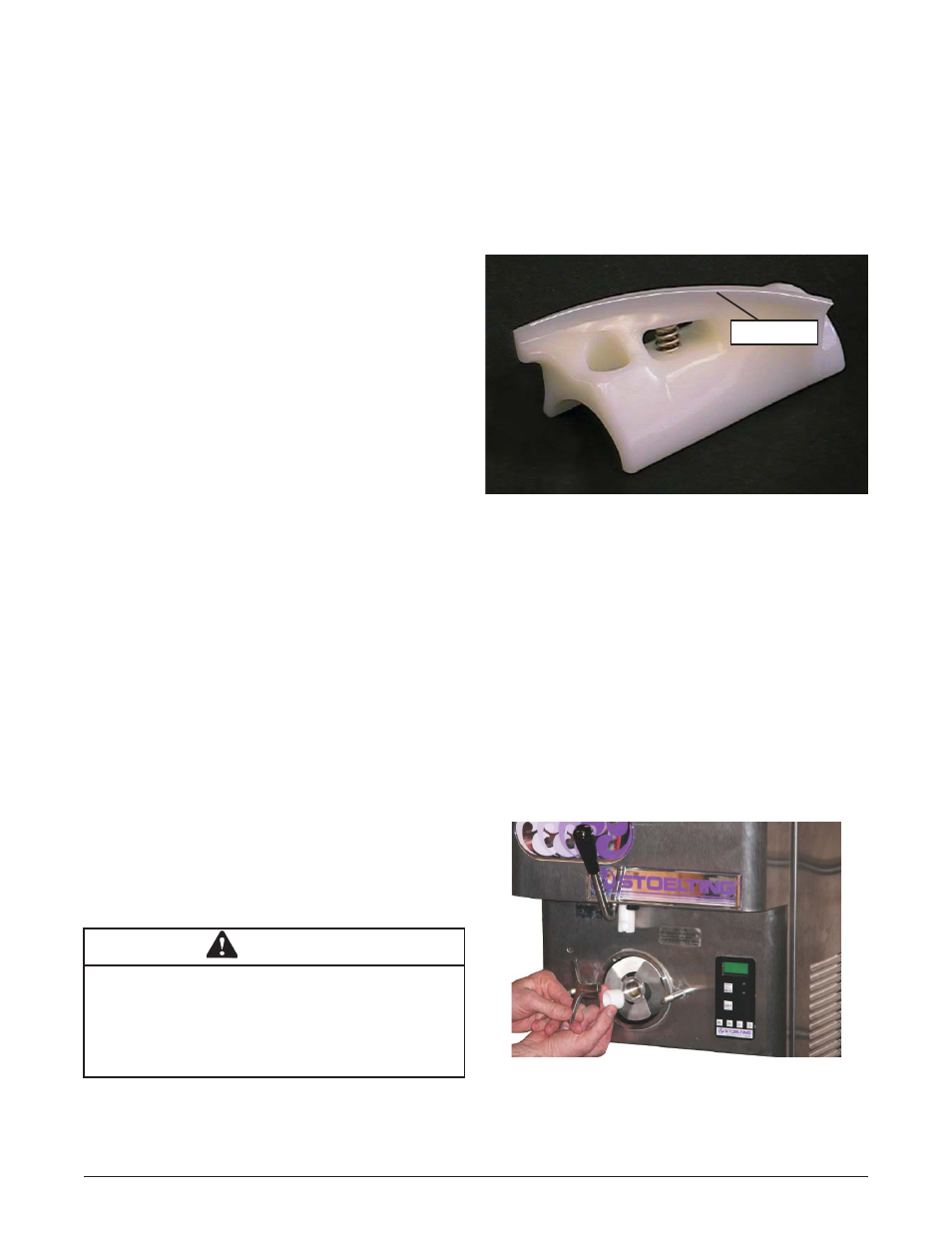

3.4 DISASSEMBLY OF PARTS

Inspection for worn or broken parts should be made each

time the machine is disassembled. All worn or broken

parts should be replaced to ensure safety to both the

operator and the customer and to maintain good machine

performance and a quality product. Check the wear line on

the auger fl ights on a regular basis (Fig. 3-3) and replace

as needed. Frequency of cleaning must comply with the

local health regulations.

To disassemble the machine, refer to the following steps:

A.

Remove hopper cover and drain tray.

B.

Remove the mix inlet regulator from the hopper

by pulling straight up.

C.

Remove the front door by turning the circular

knobs and then pulling the front door off the studs.

D.

Remove the rosette cap from the front door. Push

the spigot body through the bottom of the front

door and remove.

E.

Remove the front auger support and bushing (Fig.

3-4).

WARNING

Hazardous Moving Parts

Revolving auger shaft can grab and cause injury.

Place the Main Freezer Power OFF-ON switch in

the OFF position before disassembling for cleaning

or servicing.

Figure 3-3 Auger Flight Wear

Wear Line

Figure 3-4 Removing Auger Support