Norgren 16-004 Series Installation Instructions User Manual

Installation & maintenance instructions

TECHNICAL DATA

Fluid: Compressed air and water

Maximum pressure: 300 psig (20 bar)

Operating temperature*: -30° to +200°F (-34° to +93°C)

* Air supply must be dry enough to avoid ice formation at temperatures below

+35°F (+2°C).

Repeatability: ± 20% of relief pressure setting

Materials:

Body, cap, springrest: Brass

Valve: Brass and nitrile

Regulating spring: Stainless steel

REPLACEMENT ITEMS

The 16-004 tank relief valve is not repairable and should be replaced if it

malfunctions.

INSTALLATION

1. Shut off pressure to tank and reduce pressure in tank to zero.

2.Install relief valve in tank using pipe thread sealant on male threads only. Do not

allow sealant to enter interior of tank or relief valve.

WARNING

These products are intended for use in industrial compressed air and water

systems only. Do not use these products where pressures and temperatures can

exceed those listed under Technical Data.

To provide overpressure protection for pneumatic equipment, the flow capacity

of the relief valve selected for a specific application must be greater than the

maximum possible flow rate of the system connected to the inlet of the relief

valve.

The accuracy of the indication of pressure gauges can change, both during

shipment (despite care in packaging) and during the service life. If a pressure

gauge is to be used with these products and if inaccurate indications may be

hazardous to personnel or property, the gauge should be calibrated before initial

installation and at regular intervals during use.

Before using these products with fluids other than air, for non industrial

applications, or for life-support systems consult Norgren.

HOW TO SELECT A RELIEF VALVE

The function of the 16-004 relief valve is to retard excess pressure buildup in a

low volume air tank. Typically, a pressure regulator reduces supply pressure from

the air compressor to a suitable working pressure. Compressed air, reduced to

the working pressure, is stored in the low volume air tank. The 16-004 relief valve

is installed in the tank to vent air from the tank should pressure become

excessive. Flow capacity of the relief valve selected must equal or exceed the

flow and pressure rating of the air compressor supplying the air tank.

IM-468.520

(4/01)

Replaces NIP-703

a subsidiary of IMI plc

© Norgren 2001

16-004

Installation & Maintenance

Instructions

TANK RELIEF VALVE MODEL NUMBERS

Model Numbers - Relief Pressure Adjustment Ranges *

25 to 50 psig

25 to 75 psig

70 to 150 psig

125 to 300 psig

Port Size

(1,7 to 3,5 bar) (1,7 to 5,2 bar)

(4,8 to 10,4 bar) (8,6 to 20,7 bar)

1/8 PTF

16-004-001

16-004-002

16-004-003

16-004-004

1/4 PTF

16-004-009

16-004-010

16-004-011

16-004-012

ALTERNATIVE MODELS

Factory Set Relief Pressure Setting

Add **

Insert desired relief pressure setting 025 through

in psig

300

0

0

-

★

★ ★

★ ★

4

-

-

6

1

★ ★

Factory set, non adjustable pressure Add **

Locktite adjusting cap

Z

* Relief valves can be adjusted to pressures in excess of, and less than, those

specified. Do not use these units to control pressures outside of the specified

ranges.

** Example: 16-004-001-Z025

Locking method: Locktite cap

Relief pressure setting: 25 psig

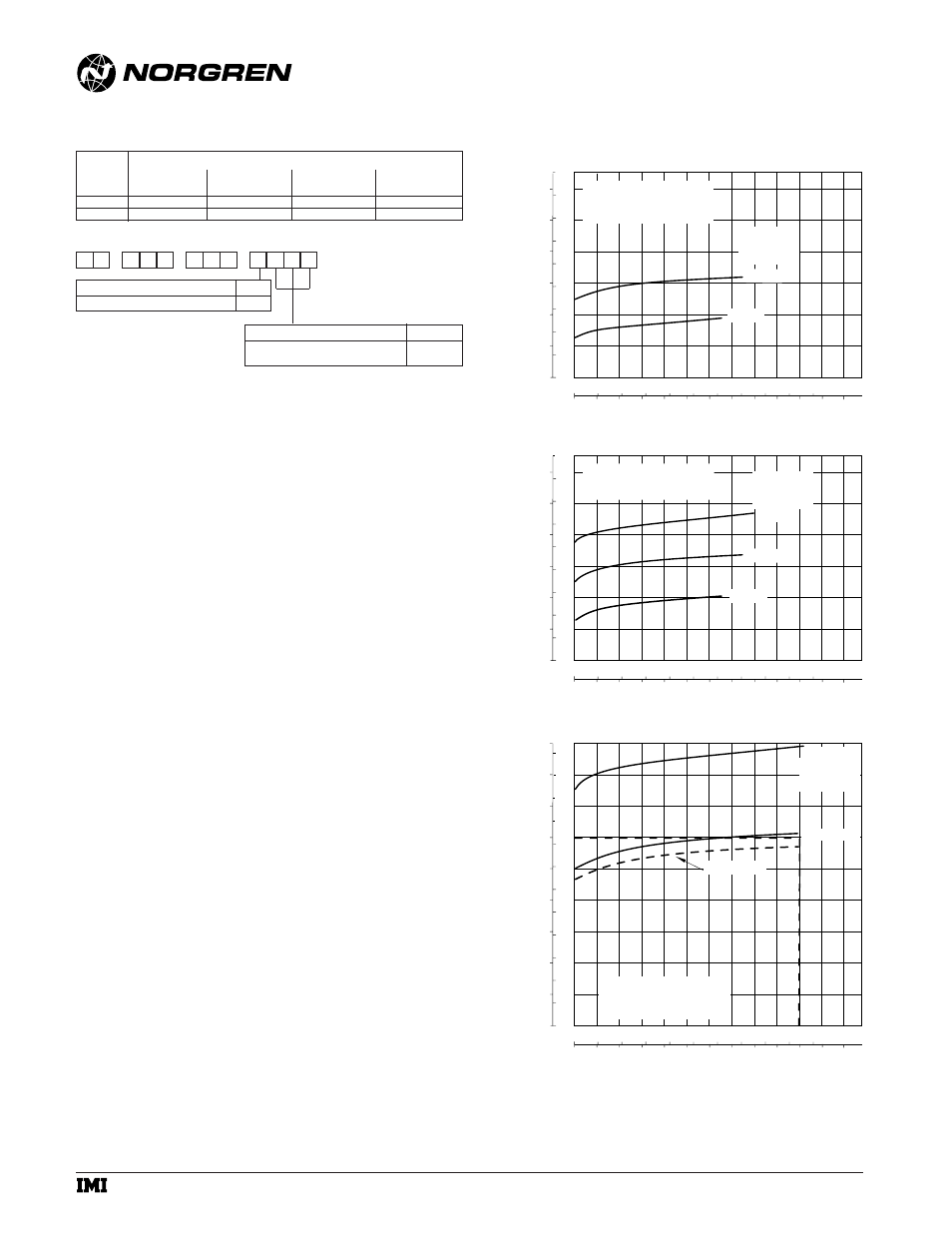

RELIEF FLOW CHARACTERISTICS - AIR

0

0,5

1

1,5

2

2,5

dm

3

/s

AIR FLOW

0

1

2

3

4

5

6 scfm

8

6

4

2

0

INLET PRESSURE

bar

100

80

60

40

20

0

psig

50 (3,5)

25 (1,7)

SET RELIEF

PRESSURE:

psig (bar)

PORT SIZE: 1/8", 1/4"

SPRING RANGE:

25 to 50 psig (1,7 to 3,5 bar)

TYPICAL PERFORMANCE CHARACTERISTICS

RELIEF FLOW CHARACTERISTICS - AIR

0

0,5

1

1,5

2

2,5

dm

3

/s

AIR FLOW

0

1

2

3

4

5

6 scfm

8

6

4

2

0

INLET PRESSURE

bar

100

80

60

40

20

0

psig

75 (5,2)

50 (3,5)

25 (1,7)

SET RELIEF

PRESSURE:

psig (bar)

PORT SIZE: 1/8", 1/4"

SPRING RANGE:

25 to 75 psig (1,7 to 5,2 bar)

RELIEF FLOW CHARACTERISTICS - AIR

0

0,5

1

1,5

2

2,5

dm

3

/s

AIR FLOW

0

1

2

3

4

5

6 scfm

8

6

4

2

0

INLET PRESSURE

bar

100

80

60

40

20

0

psig

180

160

140

120

12

10

PORT SIZE: 1/8", 1/4"

SPRING RANGE:

70 to 150 psig (4,8 to 10,4 bar)

SET RELIEF

PRESSURE:

psig (bar)

150 (10,3)

100 (6,9)

See Example

EXAMPLE: If your compressor delivers 5 scfm at 120 psig and your tank

requires a working pressure of 90 psig, the relief valve must have a set

pressure slightly higher than the 90 psig working pressure and be

capable of flowing 5 scfm at 120 psig (or pressures less than 120 psig).