044 special purpose regulator – Norgren 11-044 Series User Manual

Page 2

Littleton, CO USA

Phone 303-794-2611

www.norgren.com

2

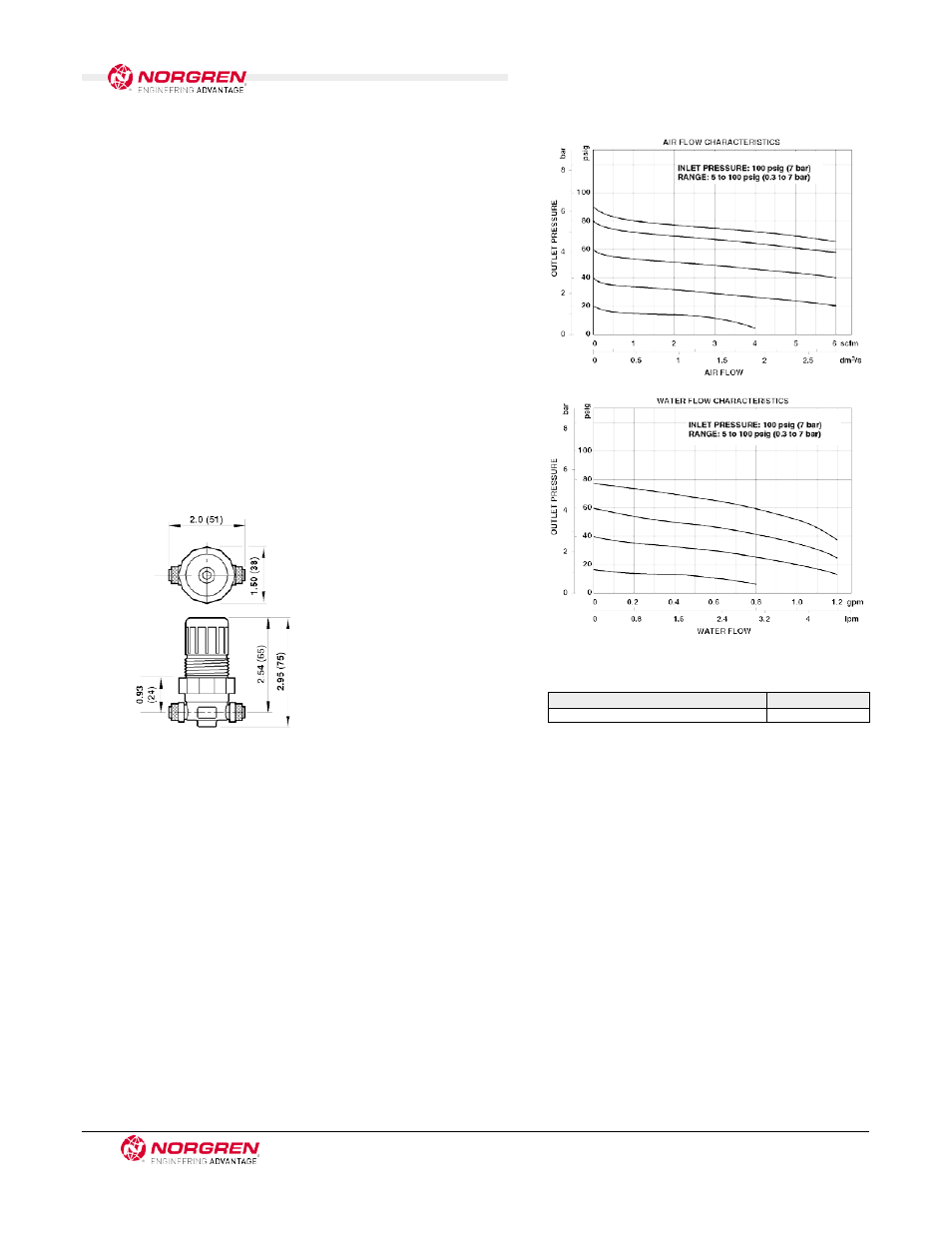

All Dimensions in Inches (mm)

11-044 Special Purpose Regulator

Technical Data

Fluid: Water and compressed air

Maximum pressure: 250 psig (17 bar)

Operating temperature:

Water service: 35° to 150°F (2° to 66°C)

Air service: -30° to 150°F (-34° to 66°C) *

* When used in air service, air supply must be dry enough to avoid ice formation at temperatures

below 35

°F (2°C).

Port connections: 1/4" OD tube (brass nut and plastic ferrule supplied)

Recommended tubing: 1/4" soft PVC or Polyethylene tubing. Avoid aluminum,

copper, and hard plastic tubing.

Typical flow:

Compressed air service at 100 psig (7 bar) inlet pressure, 90 psig (6.3 bar) set

pressure and a droop of 15 psig (1 bar) from set: 3.0 scfm (1.4 dm

3

/s)

Water service at 100 psig (7 bar) inlet pressure, 60 psig (4 bar) set pressure

and a droop of 15 psig (1 bar) from set:

0.7 U.S. gpm (2.65 liters per minute)

No gauge ports

Materials

Body: Acetal

Bonnet: Acetal

Valve: Stainless steel with EPDM seal (NSF approved)

Valve seat: Acetal

Diaphragm: Stainless steel and nitrile (NSF approved)

Panel mounting hole diameter: 1.19" (30 mm)

Maximum panel thickness: 0.25" (6 mm)

Service Kits

Type

Part number

Non-relieving

3407-59

Service kit includes slip ring, valve seat, valve, valve spring,

and diaphragm.

Typical Performance Characteristics

WARNING

These products are intended for use in industrial compressed air systems only.

Do not use these products where pressures and temperatures can exceed those

listed under Specifications.

Before using these products with fluids other than those specified, for

nonindustrial applications, life-support systems, or other applications not within

published specifications, consult NORGREN.

Through misuse, age, or malfunction, components used in fluid power systems

can fail in various modes. The system designer is warned to consider the failure

modes of all component parts used in fluid power systems and to provide

adequate safeguards to prevent personal injury or damage to equipment in the

event of such failure modes. System designers must provide a warning to end

users in the system instructional manual if protection against a failure mode

cannot be adequately provided.

System designers and end users are cautioned to review specific warnings found

in instruction sheets packed and shipped with these products. System designers

should also provide for all OSHA requirements including Title 29 CFR 1910.147

Lockout/Tagout.

It should be recognized that warnings are valid for any product, regardless of

manufacturer, and are not restricted to products manufactured by NORGREN.

NORGREN’s reputation for product quality and performance is well established.

WARRANTY

Items sold by NORGREN are warranted to be free from defects in materials and

workmanship for a period of two year from the date of manufacture, provided said

items are used according to NORGREN’s recommended usages. NORGREN’s

liability is limited to the repair of, refund of purchase price paid for, or

replacement in kind of, at NORGREN’s sole option, any items proved defective,

provided the allegedly defective items are returned to NORGREN prepaid. The

warranties expressed above are in lieu of and exclusive of all other warranties.

There are no other warranties, expressed or implied, except as stated herein.

There are no implied warranties of merchantability or fitness for a particular

purpose, which are specifically disclaimed. NORGREN’s liability for breach of

warranty as herein stated is the exclusive remedy, and in no event shall

NORGREN be liable or responsible for incidental or consequential damages,

even if the possibility of such incidental or consequential damages has been

made known to NORGREN.

NORGREN reserves the right to discontinue manufacture of any product or

change product materials, design, or specifications.