R83 pressure regulator for industrial cylinder gas, Warning, Ale-10-5 – Norgren R83 Series User Manual

Page 2: Technical data, Typical performance characteristics, Service kits

R83 Pressure Regulator for Industrial Cylinder Gas

ALE-10-5

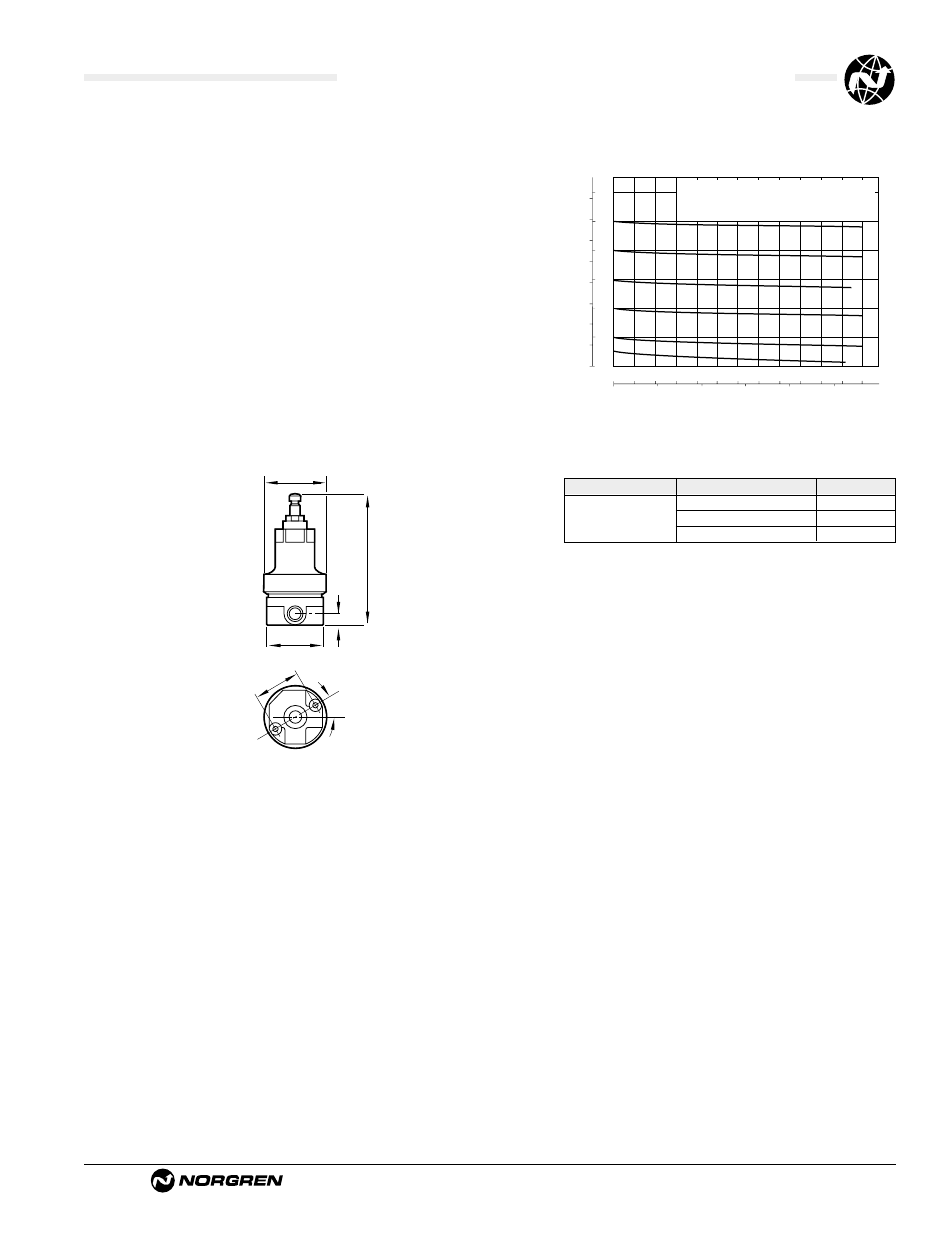

All Dimensions in Inches (mm)

Littleton, CO USA

Phone 303-794-2611

www.norgren.com

Technical Data

Fluid: Air, argon, carbon dioxide, helium, krypton, neon, nitrogen, and xenon. For

use with other gases, including oxygen, consult Norgren. Do not use the R83

regulator in beverage dispensing applications. Other Norgren regulators (R81

for soft drink, R82 for beer, R84 for carbonators) are available for use in

dispensing systems.

Maximum pressure: 3000 psig (207 bar)

Operating temperature: -30° to 140°F (-34° to 60°C) *

* Fluid must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Typical flow at 1000 psig (69 bar) inlet pressure, 60 psig (4 bar) set pressure and a

droop of 5 psig (0.35 bar) from set: 11 scfm (5.2 dm

3

/s)

Materials

Body: Brass

Bonnet: Zinc

Cartridge valve: Teflon, brass, stainless steel

Diaphragm: Acetal and nitrile

Seals: Nitrile

PORT SIZE: 1/4"

SPRING RANGE: 5 to 125 psig (0.3 to 8.5 bar)

INLET PRESSURE: 1000 psig (69 bar)

0

1

2

3

4

5

dm

3

/s

FLOW

0

2

4

6

8

10

12 scfm

OUTLET PRESSURE

8

6

4

2

0

bar

100

80

60

40

20

0

psig

FLOW CHARACTERISTICS - CO

2

Typical Performance Characteristics

30

°

1.66 (42)

1.90 (48)

4.41 (112)

2.10 (53)

0.40 (10)

Mounting Holes (2 Places)

0.18" (4.6mm) dia. by 0.39 (10mm) deep.

Use 10-32 thread forming screws.

Service Kits

Item

Type

Part number

Service kits

Diaphragm, relieving

570-51

Diaphragm, non relieving

570-10

Valve cartridge

5086-55

Valve cartridge includes the sealed cartridge and cartridge o-ring.

Warning

These products are intended for use with industrial

compressed air, argon, carbon dioxide, helium, krypton, neon,

nitrogen, and xenon. Do not use these products where

pressures and temperatures can exceed those listed under

‘Technical Data’.

Before using these products with fluids other than those

specified, for non-industrial applications, life-support systems, or

other applications not within published specifications, consult

Norgren.

Through misuse, age, or malfunction, components used in

fluid power systems can fail in various modes. The system

designer is warned to consider the failure modes of all

component parts used in fluid power systems and to provide

adequate safeguards to prevent personal injury or damage to

equipment in the event of such failure.

System designers must provide a warning to end

users in the system instructional manual if protection

against a failure mode cannot be adequately provided.

System designers and end users are cautioned to review

specific warnings found in instruction sheets packed and

shipped with these products.