Norgren L22 Series Installation Instructions User Manual

Norgren Hardware

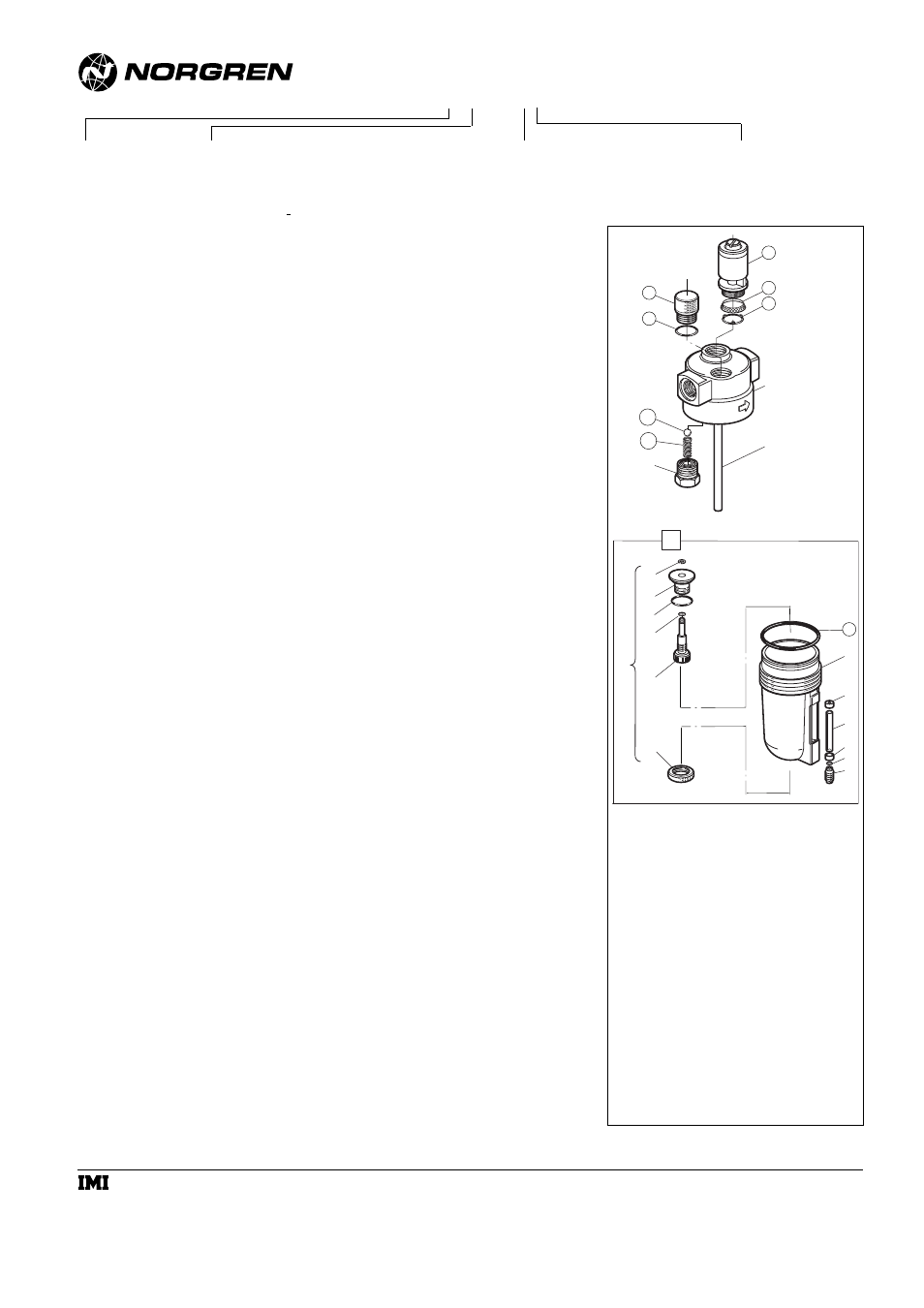

DISASSEMBLY

1. Shut off inlet pressure. Reduce pressure in inlet and outlet

lines to zero. Loosen fill plug (4).

2. Disassemble in general accordance with the item numbers

on exploded view. Do not remove the manual drain unless

replacement is necessary. Remove and replace drain

assembly only if drain malfunctions. Do not remove siphon

tube (21). Remove and replace items 22, 23, 24 only if

lubricator malfunctions.

CLEANING

1. Clean parts using warm water and soap.

2. Dry parts. Blow out internal passages in body with clean,

dry compressed air.

3. Inspect parts. Replace parts found to be damaged.

ASSEMBLY

1. Lubricate seals and o-rings with o-ring grease. Apply a

small amount of anti-seize lubricant to full length of

threads on reservoir (9) and sight feed dome (1).

2. Assemble lubricator as shown on the exploded view.

3. Torque Table

Item

Nm

(Inch-Pounds)

1 (sight feed dome)

3,4 to 4

(30 to 35)

10 (retainer)

0,8 to 1,1

(7 to 10)

15 (nut)

2,3 to 2,8

(20 to 25)

CAUTION

Do not over torque retainer (10) as damage to gauge glass

(13) will occur.

4. Turn reservoir clockwise into body until stop

(approximately 5 turns), then unscrew no more than one

full turn to position sight glass for best visibility. Do not

attempt to turn reservoir when lubricator is pressurized.

WARNING

These products are intended for use in industrial

compressed air systems only. Do not use these products

where pressures and temperatures can exceed those listed

under Technical Data.

Do not substitute any other reservoir for the stainless steel

reservoir furnished with these products.

In lubrication applications some oil mist may escape from

the point of use to the surrounding atmosphere. Users are

referred to safety and health standards for limiting oil mist

contamination and utilization of protecting equipment

Before using these products with fluids other than air, for

nonindustrial applications, or for life-support systems consult

Norgren.

TECHNICAL DATA

Fluid: Compressed air

Maximum pressure: 17 bar (250 psig)

Operating temperature: -34° to +80°C (-30° to

+175°F) *

* Air supply must be dry enough to avoid ice

formation at temperatures below +2°C (+35°F).

Start point (i.e. minimum flow required for lubricator

operation) at 6,3 bar (90 psig) inlet pressure:

1,7 dm

3

/s (3.5 scfm)

Typical flow with 6,3 bar (90 psig) inlet pressure and

0,5 bar (7 psig) pressure drop:

48 dm

3

/s (102 scfm)

Nominal bowl size: 0,2 litre (7 fluid ounce)

Materials - Metallic parts are NACE (National

Association of Corrosion Engineers) approved

metals meeting hardness requirements. NACE

Recommendation MR-01-1975 (1980 Revision)

“Material requirement - sulfite stress cracking

resistant metallic material for oil field equipment”.

Body and Bowl: Stainless steel

Reservoir sight glass and window in sight feed

dome: Pyrex

Elastomers: Nitrile

REPLACEMENT ITEMS

Service kit (items circled on

exploded view) ....................................L22-100RK

Gasket kit (items 2, 3, 5, 8) ...........................L22-GK

Bowl repair kit (items 8, 11, 12, 13) ..............5860-RK

Wall mounting bracket ..............................18-001-962

INSTALLATION

1. Shut-off air pressure. Install lubricator in air line -

●

vertically (reservoir down),

●

with air flow in direction of arrow on body,

●

downstream of filters and regulators

●

upstream of cycling valves,

●

as close as possible to the device being lubricated. Not

more than 5,2m (15 feet) from the device, and at the

same height or higher than the device.

2. Connect piping to proper ports using pipe thread sealant

on male threads only. Do not allow sealant to enter

interior of unit.

3. Before pressurizing, turn bowl clockwise into body until

stop (approximately 5 turns), then unscrew no more than

one full turn to position sight glass for best visibility.

RECOMMENDED LUBRICANTS

Use a good quality, light, misting type oil for compressed

air tools. See Norgren publication N/AL.8.900.935.

FILL RESERVOIR

Remove fill plug (4), add oil, and reinstall fill plug. Fill plug

can be removed and oil added without shutting off air

pressure to the lubricator. Oil level must always be visible

in lens on metal reservoir. DO NOT OVERFILL.

NOTE: Oil fill plug (4) seals easily. Tighten finger-tight only.

ADJUSTMENT

1. Turn on system pressure.

2. Adjust lubricator drip rate only when there is a constant

rate of air flow thru the lubricator. Monitor drip rate thru

sight feed dome (1).

3. Determine the average rate of flow thru the lubricator.

Turn drip rate adjusting screw on top of sight feed dome

to obtain one drop per minute for each 5 dm

3

/s (10

scfm). For example, if the average flow is 19 dm

3

/s (40

scfm), set the drip rate at 4 drops per minute. Turn

adjusting screw counterclockwise to increase and

clockwise to decrease the drip rate.

4. Monitor the device being lubricated for a few days

following initial adjustment. Adjust the drip rate if the oil

delivery at the device appears either excessive or low.

1

22

2

4

6

5

3

7

24

23

21

16

17

18

19

20

15

14

10

11

12

9

13

8

12

L22

Installation & Maintenance

Instructions

Stainless Steel Oil-Fog Lubricator

L22 -

★0★ - OP★★

Thread Form

A....PTF

D....ISO G

S....Special ported 3/4-16 UNF †

Port

4 ....1/2"

6 ....Special ported

3/4-16 UNF †

Reservoir

8 ....Closed bottom or plugged open bottom

D....Open bottom with manual drain

IM-520.400

(5/02)

Replaces NIP-345

a subsidiary of IMI plc

© Norgren 2002

Option

0 ....Closed bottom reservoir

5 ....Open bottom reservoir with plug or manual drain

7 ....Special ported 3/4-16 UNF equipped with

open bottom reservoir with plug or manual drain †

† Special ported 3/4-16 UNF model: L22-607- OP x S. Reservoir type indicated in position 9 of model number.