B74g, Installation & maintenance instructions – Norgren B74G Series Installation Instructions User Manual

Page 2

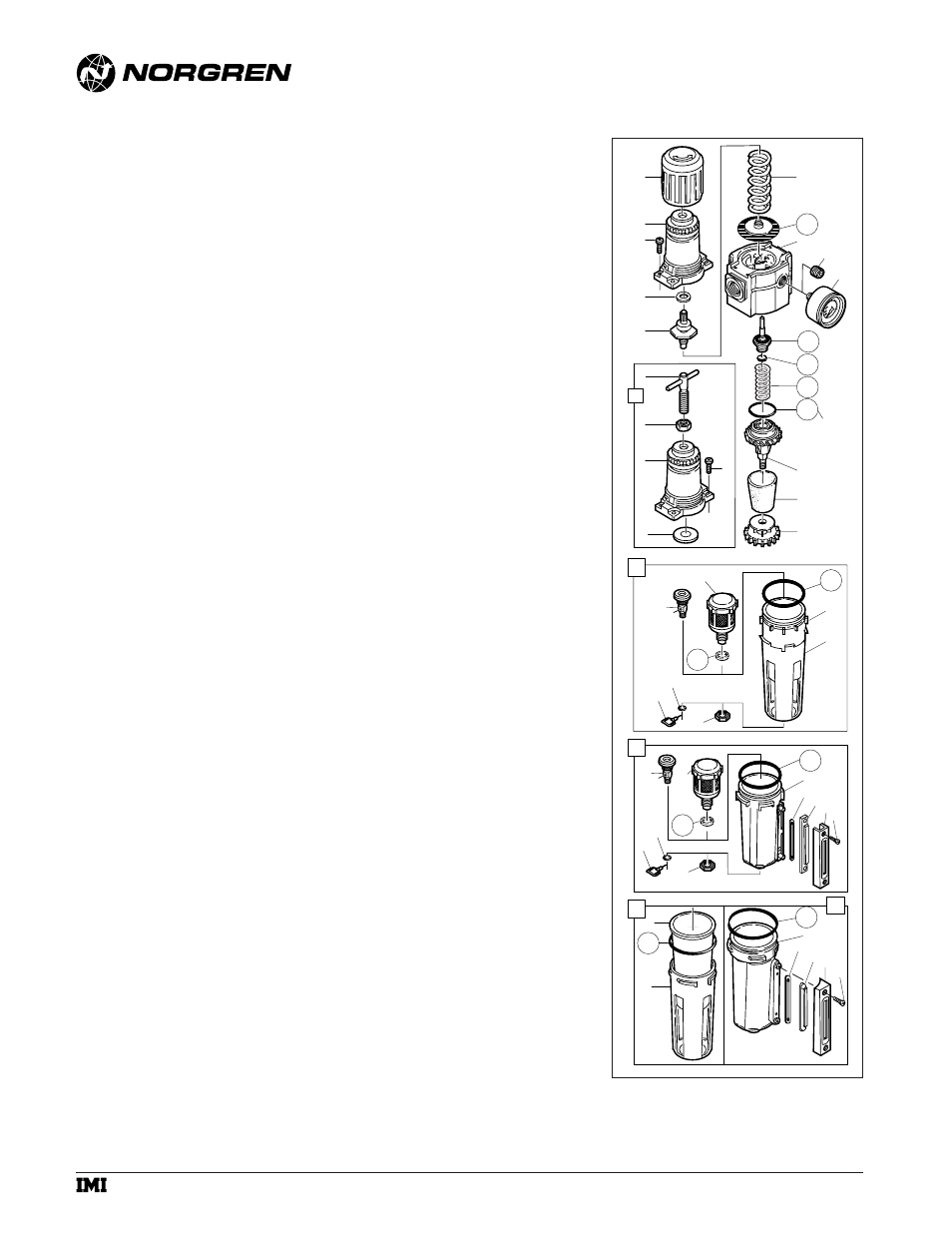

ASSEMBLY

1. Lubricate the following items with o-ring grease.

4 (Thrust washer) - outer circumference and both sides.

5, 7 (Adjusting screw) - threads and tip.

18, 28 (Manual drain body) - the portion of the body

that contacts the bowl, and the hole that

accommodates the stem of drain valve (19, 29).

56 (Valve) - stem.

26, 38, 43, 49, 54, 57 (O-rings)

2. Assemble the unit as shown on the exploded view. Push

bowl, or bowl with guard, into body and turn fully

clockwise.

3. Torque Table

Item

Torque in Nm (Inch-Pounds)

2, 10 (Screw)

2,3 to 3,9 (20 to 35)

22, 32 (Nut)

2,3 to 2,8 (20 to 25)

34, 45 (Screw)

1,7 to 2,3 (15 to 20)

53 (Center-post)

2,0 to 2,7 (18 to 24)

50

34

35

36

39

37

38

33

28

31

30

29

32

27

Current Metal Bowl

40

Early Plastic Bowl

Early Metal Bowl

44

49

Current Plastic Bowl

17

26

25

24

23

21

18

20

19

22

45

46

48

47

42

41

43

6

1

3

2

4

5

7

8

9

11

10

12

13

16

14

15

56

57

55

53

52

51

54

Used on

models

prior to

1998

© Norgren 1998

B74G

Installation & Maintenance

Instructions

CAUTION

Water vapor will pass through these units and could

condense into liquid form downstream as air temperature

drops. Install an air dryer if water condensation could have

a detrimental effect on the application.

WARNING

These products are intended for use in industrial

compressed air systems only. Do not use these products

where pressures and temperatures can exceed those listed

under Technical Data.

Polycarbonate plastic bowls can be damaged and

possibly burst if exposed to such substances as certain

solvents, strong alkalies, compressor oils containing ester-

based additives or synthetic oils. Fumes of these

substances in contact with the polycarbonate bowl,

externally or internally, can also result in damage. Clean

with warm water only.

Use metal bowl in applications where a plastic bowl

might be exposed to substances that are incompatible with

polycarbonate.

If outlet pressure in excess of the filter/regulator

pressure setting could cause downstream equipment to

rupture or malfunction, install a pressure relief device

downstream of the filter/regulator. The relief pressure and

flow capacity of the relief device must satisfy system

requirements.

The accuracy of the indication of pressure gauges can

change, both during shipment (despite care in packaging)

and during the service life. If a pressure gauge is to be

used with these products and if inaccurate indications may

be hazardous to personnel or property, the gauge should be

calibrated before initial installation and at regular intervals

during use.

Before using these products with fluids other than air,

for non industrial applications, or for life-support systems

consult Norgren.

a subsidiary of IMI plc

IM-200.300.02

(9/98)

Supersedes 4/98