Blade sharpening, Blade removal, Blade sharpening -7 blade removal -7 – Alamo FALCON 15/10 User Manual

Page 143: Maintenance

MAINTENANCE

FALCON 15/10 03/09

Maintenance Section 5-7

© 2009 Alamo Group Inc.

MAINTENANCE

BLADE SHARPENING

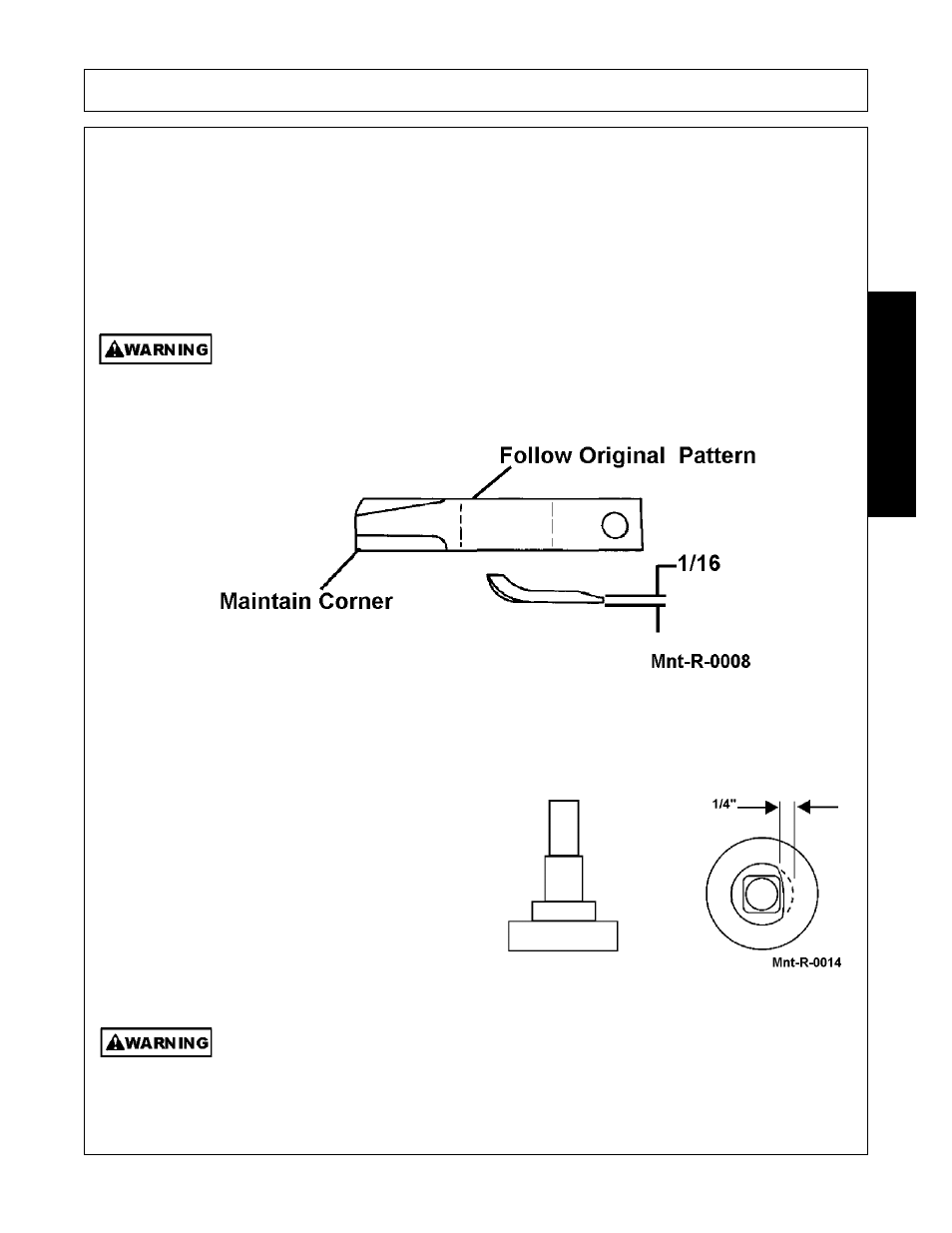

Always sharpen both blades at same time to maintain balance. Follow original sharpening pattern as shown in

FIGURE 19. Always sharpen blades by grinding. DO NOT heat and pound out edge. Do not sharpen blade to

a razor edge, but leave a 1/16" blunt edge. Do not sharpen back side of blade.

IMPORTANT: When sharpening blades, grind each blade the same amount to maintain balance. The

difference in blade weights should not exceed 1 ounce. Unbalanced blades will cause excessive vibration

which can damage bearings and break welds and other components. Vibration may also cause structural

cracks in cutter housing.

Never work under equipment supported by a hydraulic device because it may drop if the

control is actuated (even with the engine stopped) or in the event of hose failure, etc.

Always use a secure support for equipment which must be serviced while in the raised

position.

NOTE: Replace Blades in pairs after no more than 1/2" notch wear!

BLADE REMOVAL

To remove blades for sharpening or replacement,

remove the cover plate on deck of cutter near gear

box. Remove lock nut from blade bolt (left hand

threaded bolt). NOTE: Inspect lock nut after

removal and replace if threads are damaged.

Always replace nut when replacing blade bolt.

When installing blades be sure and check blade bolt

pivot diameter for wear. Replace bolt if worn more

than 1/4 inch at any point. See Figure Mnt-R-0014.

Install blade bolts with partially worn side of bolt

either toward or away from center. Tighten lock nut

to 300 ft. lbs.

Avoid personal injury. Blade and/or blade carrier removal should be done only with the

tractor engine shut off, key removed, in neutral, parking brake on, PTO disengaged, and the

cutter blocked in the raised position.