Important, Good better best not recommended – FMI Q431 "Q User Manual

Page 3

result in as much as 20% motor speed reduction

when the pump is operating against a significant

head pressure.

e) THE FLOW STABILITY (precision) of an FMI

PUMP is therefore principally related to consis-

tency in fluid slip rate and stroke repetition rate and

these functions in turn are related to external sys-

tem load factors such as viscosity, differential pres-

sure and electric line voltage; i.e., when load

factors remain essentially constant, slip rate and

repetition rate remain essentially constant; when

viscosity increases, fluid slip rate and stroke repe-

tition rate both decrease; when differential pres-

sure increases fluid slip rate increases and stroke

repetition rate decreases. In short, FMI PUMP

PRECISION is influenced by fluctuations of fluid

differential pressures, fluid viscosity and electric

line voltage. When these factors are controlled pre-

dictably reproducible pumping precision better

than 0.5% may be expected.

MAINTENANCE & REPAIR

INSTRUCTIONS

14. LUBRICATION. Pump drive elements are pro-

vided with oil fittings at all appropriate points. Use

high grade machine oil at regular intervals. A dab

of good grease on PISTON DRIVE PIN just before

it is inserted into the RADIAL BEARING in the

SPINDLE ASSEMBLY does a world of good for the

bearing and pin.

15. CHANGING THE LIQUID END OF YOUR FMI

“Q” PUMP. (figures 1,2).

a) To remove “Q” Pump Head Module (QPHM):

1. Turn power off.

2. Rotate STROKE LENGTH ADJUSTMENT

KNOB to position PUMP HEAD CARRIER Q410-

2 all the way to the extreme right or left of scale

(fig. 1).

3. Rotate SPINDLE ASSEMBLY Q424 to place

PISTON DRIVE PIN at 3 or 9 o’clock position (fac-

ing cylinder head).

4. Loosen two KNURLED NUTS.

5. Lift QPHM and draw gently away from Q424

SPINDLE ASSEMBLY(fig. 2).

6. Move QPHM up and to the left while slipping

DRIVE PIN out of RADIAL BEARING.

b) To replace QPHM:

1. With PISTON ASSEMBLY R423 extending ap-

proximately 1-1/4" from CYLINDER NUT R406K

and DRIVE PIN in the 3 or 9 o’clock position, in-

sert PIN into the RADIAL BEARING in the SPIN-

DLE ASSEMBLY.

2. Slide QPHM into position on BASE making sure

locator on bottom of CARRIER Q410-2 drops into

slotted portion of FOLLOWER Q454-2 on base.

3. Tighten KNURLED NUTS on Q616 assembly

16. CHANGING FITTINGS ON STAINLESS

STEEL PUMP HEADS

IMPORTANT!

Fittings screwed too tightly into stainless steel

pump heads will contact port seals and may cause

piston/cylinder damage. Use extra layers of Teflon

tape on threads when necessary to avoid such ex-

cessive penetration.

17. CLEANING PUMP HEAD. Routine flushing

with solvent before shut-down will suffice for most

applications - set pump for maximum stroke and

operate until solvent appears clear at discharge

port. If periodic teardown for detail cleaning is re-

quired, remove parts with care to avoid damage to

piston, cylinder and gland. Wipe all parts with lint-

less oil saturated cloth. Operate by hand after re-

assembly to assure free movement of parts prior to

application of power.

17.1 CAUTION! Ceramic piston/cylinder sets are

particularly sensitive to neglect and may “freeze”

if allowed to dry out without adequate cleansing.

Some users actually remove the piston from the

cylinder after solvent cleaning and store the com-

ponent parts in disassembled condition until the

pump is again required. Others fill a loop of flexible

tubing with fluid that will thin or neutralize the last

fluid pumped. They then connect one end of the

tube to the pump suction port, the other to the dis-

charge port. With this loop positioned above the

pump head, the ceramic surfaces and seal areas

will stay moist and mobile for extended idle peri-

ods. If, however, a piston (ceramic or stainless

steel) does freeze in the cylinder, DO NOT TRY

TO FORCE IT FREE! Be gentle. Try to remove

the pump head (refer para 15) from the base as-

sembly so that the whole assembly can be soaked

in a suitable solvent. If the head is not conve-

niently removable, the tube loop discussed in the

prior paragraph may permit solvent to dissolve the

“frozen” residue in reasonable time. Having a

spare pump head on hand in case of emergency is

always a good idea.

17.2 SANITARY SERVICE. FMI sanitary pump

heads, designated SAN are designed to conform

with the cleansing standards of the U.S. Food and

Drug Administration.

To clean individual component parts:

a)Unscrew 2 CYLINDER NUTS R406-S and 2

PORT NUTS 110348-P.

b)Remove piston and seal components released

by step a) above;

c)Use fingers to wiggle LINER R407-C slipping it

from CYLINDER CASE R405-SAN;

d)Cleanse and sterilize component parts as per

government regulations for parts manufactured of

Alumina Ceramic, Type 316 Stainless Steel and

Teflon. After cleaning, reassemble the components

as follows:

e)Assemble piston/seal components as per in-

structions para 18 a,b,c;

f)Orient CYLINDER LINER R407-C in CYLINDER

CASE R405-SAN in such a manner that the side

port flats on CYLINDER LINER R407-C should be

visible through the side port openings on CYLIN-

DER CASE R405-SAN.

g)Place one each port seal component R412-T

into each side port of CYLINDER CASE R405-

SAN using finger pressure across the two ports

to assure flush seating of the seal surfaces on

the cylinder liner flats.

h)Apply PORT NUT 110348-P to each port, finger

tight.

i)Carefully insert piston into cylinder liner until

threads of CYLINDER NUT

R406-S meet threads of CYLINDER CASE R405-

SAN. Tighten NUT R406-S finger tight.

Continued on Page 12

3

IN-Q431-09A

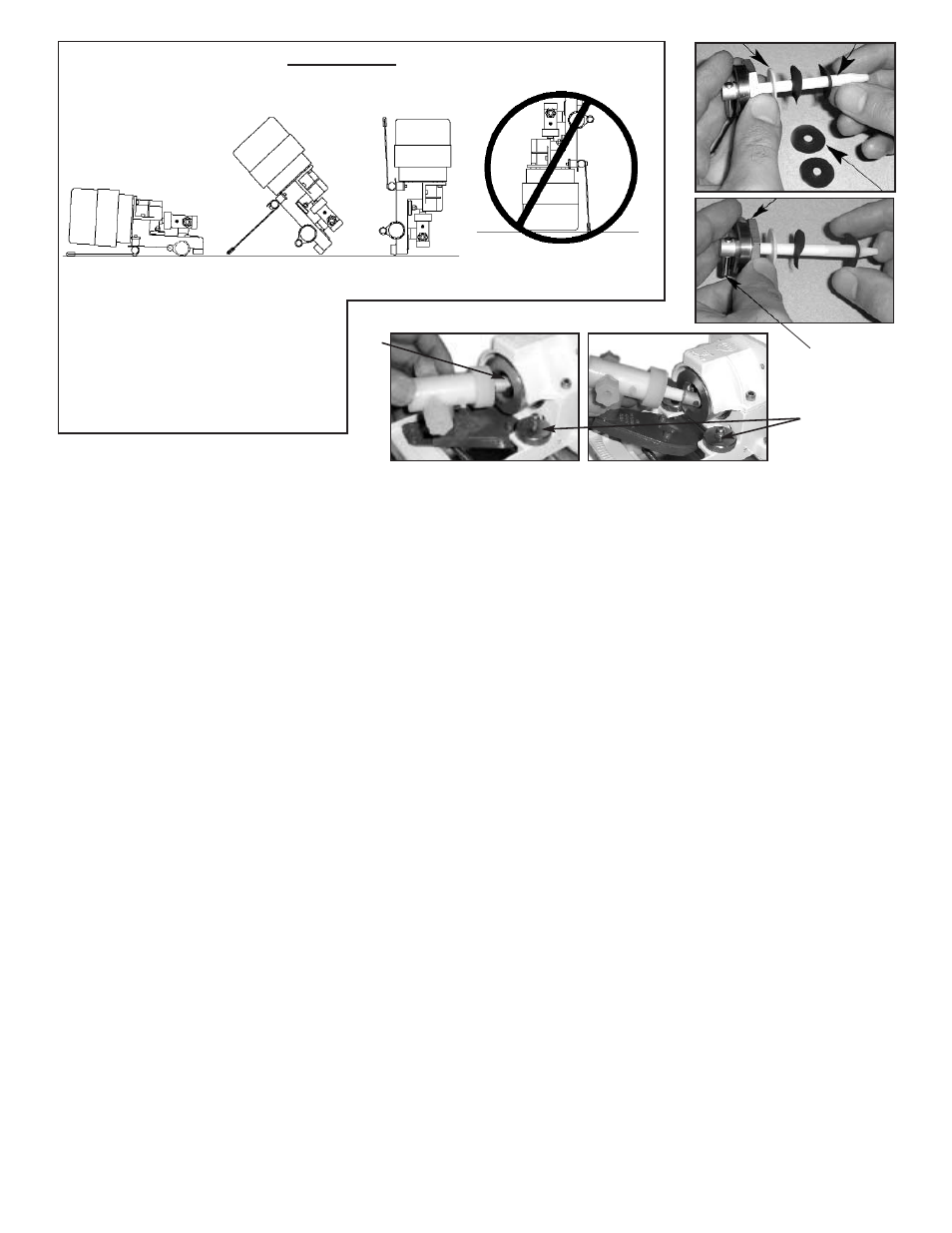

For maximum pump performance, mount

the pump with motor at 12 o’clock and

pump head at 6 o’clock position. This ori-

entation will allow air bubbles that enter

the pumping chamber to directly exit thru

buoyant assist. Discharge lines should be

inclined upward from pump head.

IMPORTANT

RECOMMENDED FMI PUMP MOUNTING FOR MAXIMUM

PERFORMANCE

GOOD

BETTER

BEST

NOT

RECOMMENDED

figure 1

figure 2

KNURLED

NUTS

Q424

R408

R409

figure3

figure 4

DRIVE PIN

R423

R406