FMI Q431 "Q User Manual

Page 12

Continued from page 3

j) Place head seal components R413 and R489

into the head end of CYLINDER CASE R405-

SAN, apply CYLINDER NUT R406-S..

k) Wrench tighten each PORT NUT 110348-P 1/6

turn.

l) Wrench tighten each CYLINDER NUT R406-S

1/2 turn, piston end first.

18. PISTON SEAL REPLACEMENT (please see

para 5.) When R408 SEALS are replaced, the

following procedure should be followed: (please

see figs. 3,4)

a) Place GLAND NUT R406 and GLAND

WASHER R409 on PISTON ASSEMBLY R423.

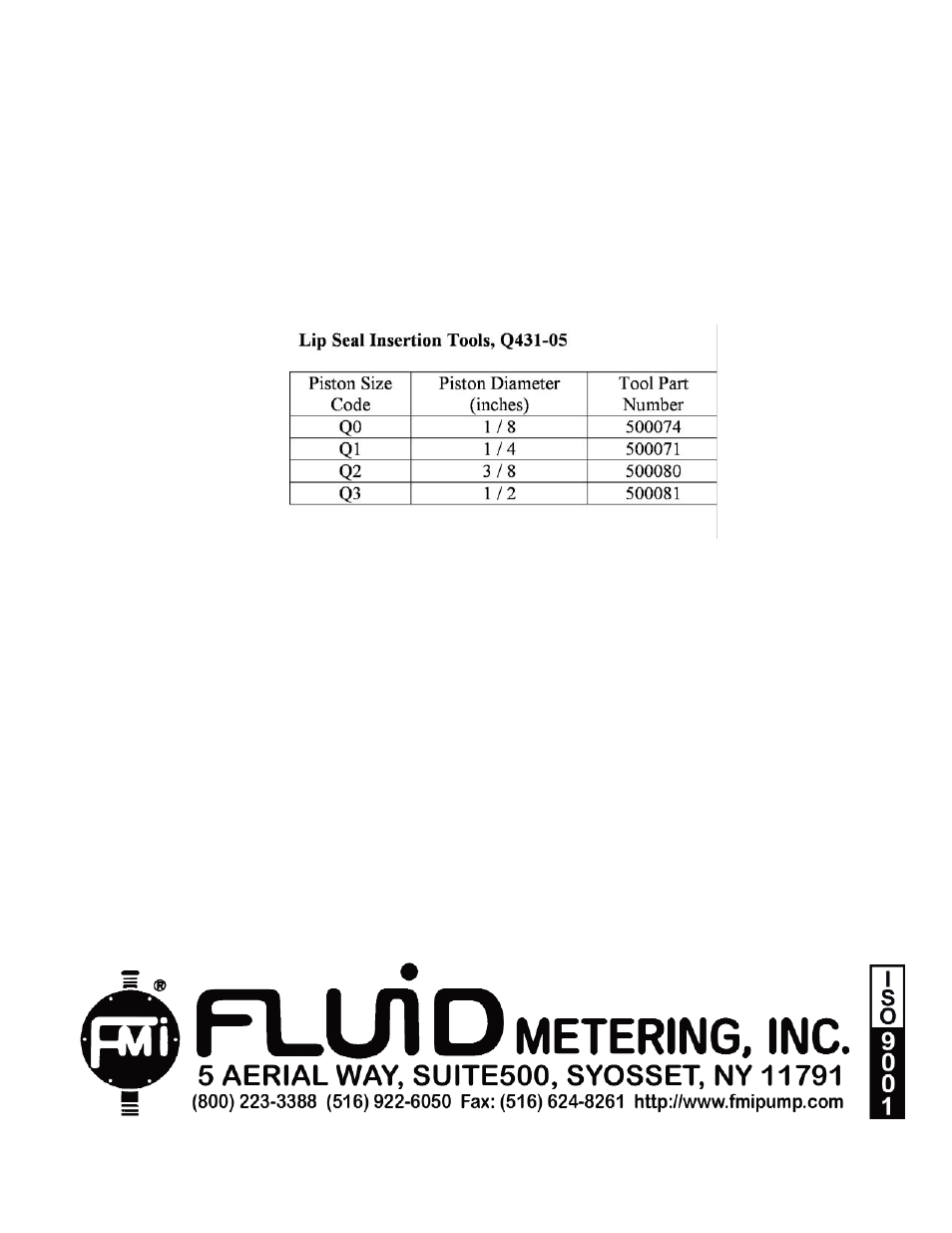

b) Place the lip seal installation tool over the end

of the piston. Slide the tool until piston is seated

in tool. (See lip seal insertion tool table bellow).

c) First “Form” lip of lip seal by gently placing a

lip seal R408 on tool, lip side last. Carefully ro-

tate the seal on the tool while sliding the seal

over the tool’s neck to avoid damage to the lip.

Then remove seal and reverse lip direction

(FIG.3)

d) Gently place one “formed” LIP SEAL R408 on

piston, lip side first, carefully rotating the seal on

the tool until it is past the tool and on the piston

e) Gently place one LIP SEAL R408 on piston,

lip side last. Carefully rotate the seal on the tool

to avoid damage to the lip while passing over the

tool to the piston (fig. 4).

f) Remove installation tool from the piston.

g) Insert piston into cylinder approximately one

inch.

h) Apply GLAND NUT R406 to cylinder threads,

seat gland nut, then tighten to 1/3 turn maximum.

19. PISTON SEAL SETTING. After installing

new

lip seals (part R408) in pump head it is recom-

mended that the seals be set (formed in place)

by fluid pressures generated by pump action. To

accomplish this:

a) Operate the pump spindle clockwise for 10 or

20 strokes at maximum setting, handling water

(left to right mode facing pump head) with suction

line blocked or pinched off. This will create a

vacuum in the pump head, permitting atmos-

pheric pressure to shape the outer seal member

tightly around the piston.

b) Reverse the pumping direction (pump head

angle reversal) and intermittently block the line

leading from the left hand port. This will generate

pressure in the seal area of the pump head,

causing the inner seals to form intimately around

the piston.

12

IN-Q431-09A

WHEN ORDERING REPLACEMENT PARTS PLEASE MENTION MODEL AND SERIAL NUMBERS OF

THE PUMP ON WHICH THEY WILL BE USED.

Record your Model and Serial Numbers below. This will be useful when ordering replacement parts.

PUMP HEAD MODULES (PHM)

PUMP DRIVE MODULE (PDM)

PHM MODEL NUMBER

PHM SERIAL NUMBER

PDM MODEL NUMBER

PDM SERIAL NUMBER

_____________________ QB__________________ _____________________ QA__________________

_____________________ _____________________ _____________________ ____________________

_____________________ _____________________ _____________________ ____________________

_____________________ _____________________ _____________________ ____________________

PLEASE NOTE:

Pistons and cylinders are dimensionally mated. For most satisfactory performance, they should be ordered

as mated sets.