Advantages of cs1601 over l6562, 1 smaller boost inductor, 2 lower total harmonic distortion (thd) – Cirrus Logic AN349 User Manual

Page 2: 3 light load performance, 4 near unity power factor, An349, Figure 2. comparison of thd vs. ac line voltage

AN349

2

AN349REV1

3. Advantages of CS1601 over L6562

The CS1601 uses a revolutionary digital algorithm that has significant advantages over the existing analog CRM-based L6562.

The major advantages are described in the following sections.

3.1 Smaller Boost Inductor

The CS1601 has a digitally implemented variable-frequency, discontinuous conduction mode (VF-DCM) -based algorithm that

permits delivering the same power and the same peak current ratings with a significantly smaller inductance. This results in an

inductor which is considerably smaller in physical dimensions. In the fluorescent ballast application introduced in Section 2, mi-

gration from a L6562-based solution to one using the CS1601 resulted in the inductor being 45% smaller. The same inductor

could be wound with 26% fewer turns or in a smaller core size which would result in a more compact design. The 2x EE19 core

sets used in some L6562-based fluorescent ballasts could be replaced with a single EE25 inductor reducing the total cost and

size of the final solution.

3.2 Lower Total Harmonic Distortion (THD)

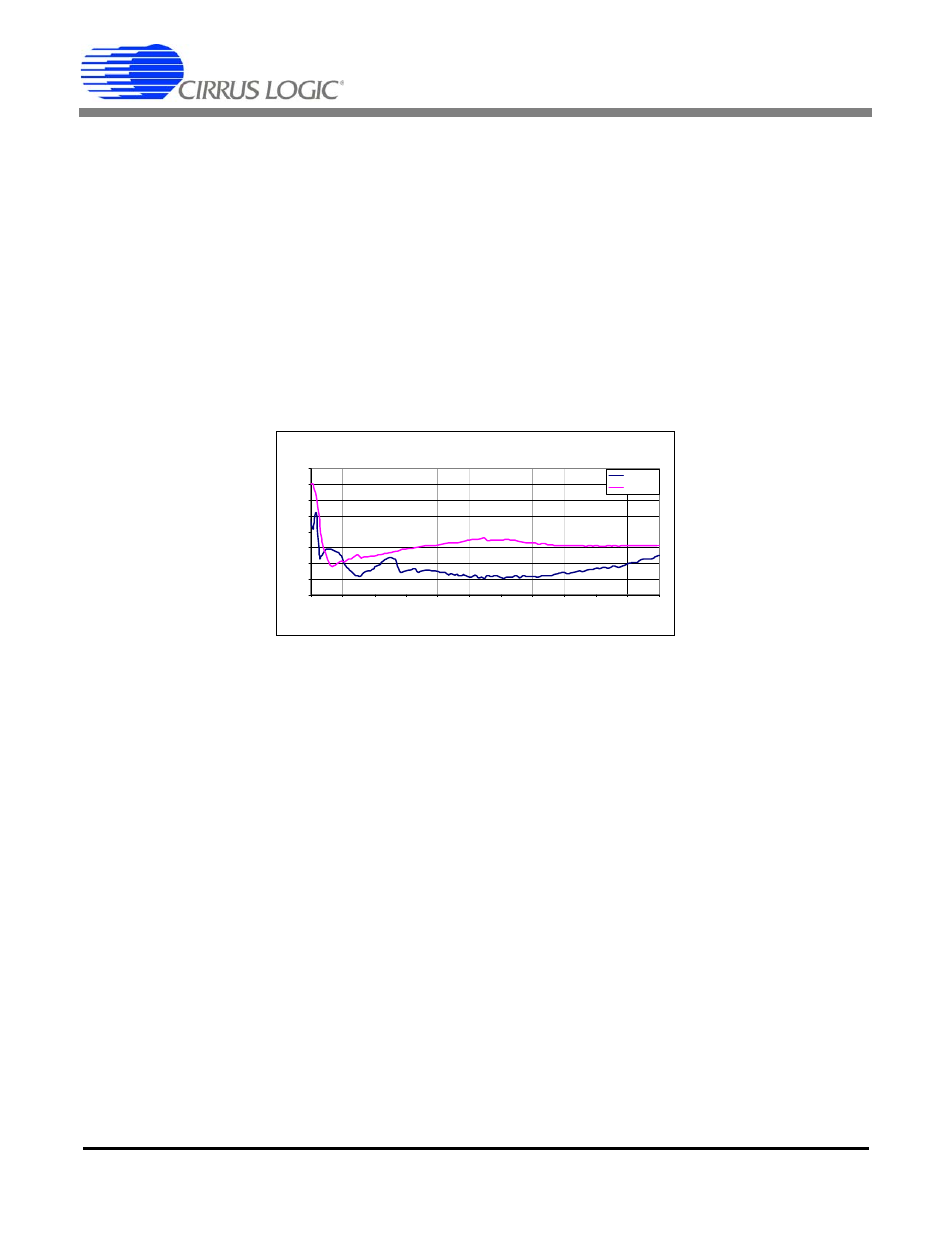

The CS1601-based design has lower THD than the L6562-based solution. In the fluorescent ballast example, it can be seen that

the THD across the line at full load was more than 2.5% lower than L6562 as shown in Figure 2.

Figure 2. Comparison of THD vs. AC Line Voltage

The L6562 cannot support large differential filter capacitors on the DC side of the bridge rectifier. In CRM controllers, the maxi-

mum switching frequency at the trough of the AC line is theoretically infinity. The L6562 sets a limit on this maximum, increasing

distortion of the AC line when a larger capacitor is placed across the rectified (DC) AC line. The L6562-based ballast necessitates

expensive AC capacitors placed on the AC line side of the bridge rectifier, increasing the cost of the EMI filter. Since the THD in

the CS1601-based solution is significantly lower, it allows the designer to reduce the EMI filter cost by moving a substantial por-

tion of the differential filter capacitance to the DC side of the bridge rectifier. This eliminates the need for expensive AC capacitors

and reduces overall bill of material (BOM) cost.

3.3 Light Load Performance

The flexibility of moving filters to either side of the rectifier also offers another significant advantage over the L6562 with respect

to light-load PF and high-line-voltage THD. In traditional analog solutions, placing capacitors at the output of the bridge rectifiers

increases THD, especially at light-load conditions and high line voltage. At the trough of the AC line, CRM controllers run at very

high frequencies and switch intermittently to limit switching losses. Placing capacitors at the input side of the bridge reduces PF

since the EMI capacitor swings to twice the input voltage. Power supply designers have to make trade-offs between light load

efficiency, power factor, and THD. The L6562 has errors and delays resulting from the multiplier, comparator, and gate drivers.

These result in errors in peak current at light loads. In the trough these cause significant deterioration of THD performance. As a

workaround to this problem, traditional CRM controllers have to greatly increase the inductance of the boost inductor to limit the

slope of the current and limit the error in peak current that is caused. Since the CS1601 is a variable-frequency DCM controller

with different frequency profile, the limitations encountered when using the L6562 are not present in a system designed with the

CS1601. The CS1601 offers optimal performance with minimal design constraints.

3.4 Near Unity Power Factor

Improved THD performance necessitates large AC capacitors for differential mode EMI filters. Because the voltage swing on ca-

pacitors on the AC line side of the bridge rectifier is twice that of the capacitors placed on the DC side of the bridge, power factor

is reduced. Figure 3 compares the PF between the L6562-based ballast and the CS1601-based ballast. The CS1601 maintains

THD Vs Line @ 60Hz

0

2

4

6

8

10

12

14

16

80

100

120

140

160

180

200

220

240

260

280

300

Line Voltage (V)

% TH

D

CS1601

ST L6562