2 switch overpower protection, 4 voltage clamp circuit, 1 clamp overpower protection – Cirrus Logic CS1616 User Manual

Page 9: 6 dual-mode flyback / buck-boost, 6 dual-mode flyback/buck-boost, Figure 12. clamp pin model, Figure 13. flyback model

CS1615/16

DS961F1

9

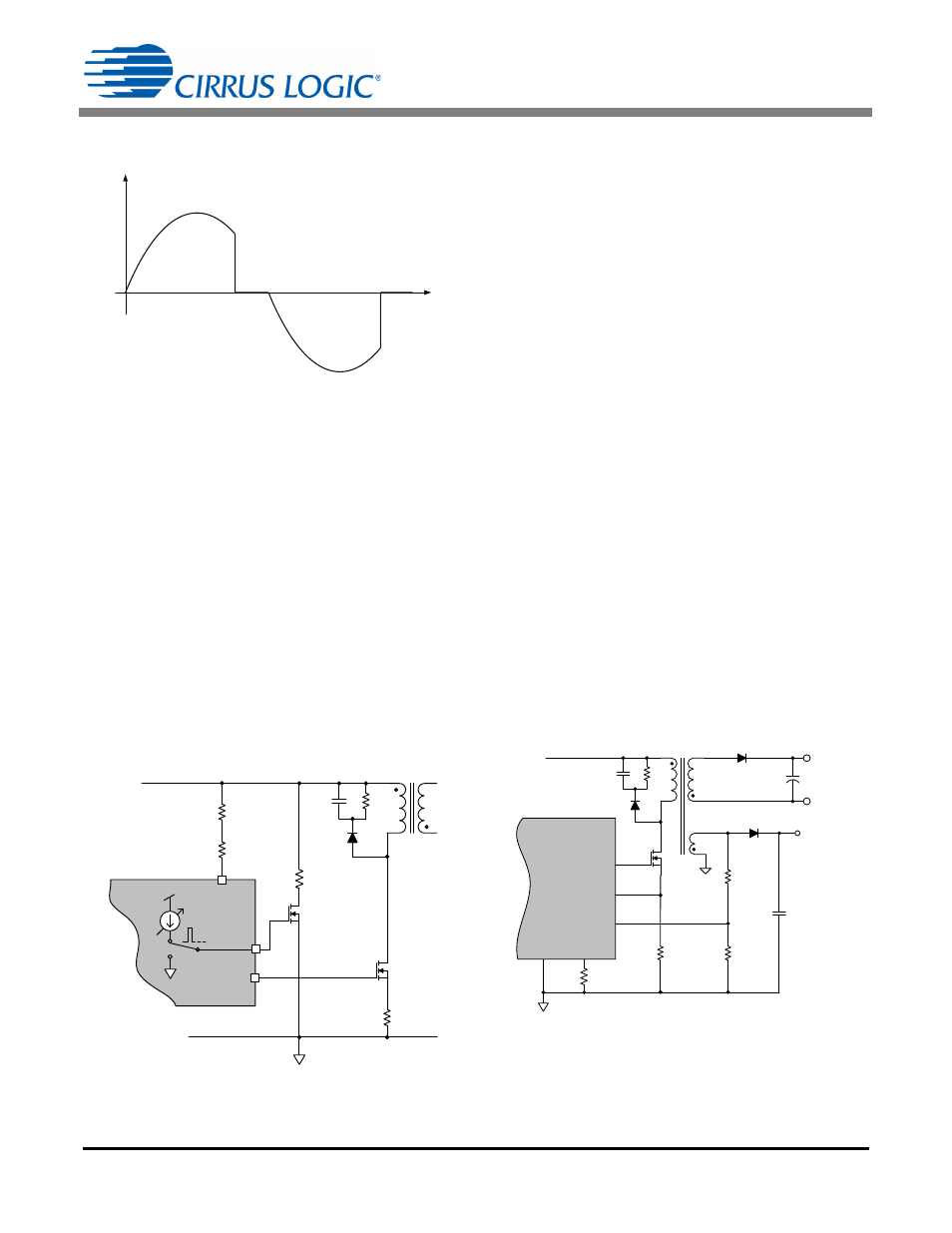

dimmer switch on the falling edge of the input voltage using a

source-controlled dimmer-compatibility circuit.

5.3.2 Switch Overpower Protection

To prevent excessive power dissipation on the source-switched

FET Q1, the CS1615/16 monitors voltage across FET Q1 and

current flow through FET Q1 to calculate average power

dissipation. If the calculated power exceeds the overpower

protection threshold a fault condition occurs. The IC output is

disabled and the controller attempts to restart after

approximately thirty seconds.

5.4 Voltage Clamp Circuit

To keep trailing-edge dimmer switches conducting and from

misfiring, the dimmer switch internal capacitor has to be

charged quickly around the trailing edge of the phase-cut

waveform. In addition to the dimmer compatible circuit, an

optional clamp circuit provides a high-current sinking path for

delivering the required amount of charge onto the dimmer

switch capacitor in a short amount of time.

The CS1615/16 provides active clamp circuitry on the CLAMP

pin, as shown in Figure 12.

5.4.1 Clamp Overpower Protection

The CS1615/16 clamp overpower protection (COP) control logic

averages the turn-on time of the clamp circuit. If the output of the

averaging logic exceeds 10%, a COP event is actuated. The

clamp circuit is disabled as well as the flyback/buck-boost

controller and the dimmer-compatibility circuit. The COP fault

state is not cleared until the power to the IC is recycled.

5.5 Dimmer Angle Extraction and the Dim

Mapping Algorithm

When operating with a dimmer, the dimming signal is extracted

in the time domain and is proportional to the conduction angle of

the dimmer. A control variable is passed to the quasi-resonant

flyback/buck-boost controller to achieve a wide range of output

currents.

5.6 Dual-mode Flyback/Buck-boost

The CS1615/16 is configurable for isolated or non-isolated

topologies using a flyback transformer or buck-boost inductor,

respectively. The CS1615/16 controls the dual-mode

flyback/buck-boost to satisfy the dimmer hold current

requirement in Dimmer Mode and provide power factor

correction in No-dimmer Mode. The dual-mode ensures a

minimum average input current greater than the required dimmer

hold current when behind a dimmer and shapes the line current

when not behind a dimmer to provide power factor correction. It

also ensures half line-cycle averaged constant output current.

Figure 13 illustrates the dual-mode flyback topology. The

CS1615/16 regulates output current using primary-side control,

which eliminates the need for opto-coupler feedback. The control

loop operates in peak current control mode. Demagnetization

time of the transformer is sensed by the FBAUX pin using an

auxiliary winding and is used as an input to the control loop.

Figure 11. Trailing-edge Mode Phase-cut Waveform

CLAMP

R

Clam p

I

CLAM P

V

rect

S1

CS1615/16

VDD

Q

T1

R4

D3

R6

C6

R5

Q3

R

Sense

3

13

GD

2

IAC

Figure 12. CLAMP Pin Model

R

CTRL2

CTRL2

FBAUX

GND

GD

9

12

CS1615/16

16

13

T1

D3

R6

C6

Q3

R

S ense

V

rect

FBSENSE 11

C7

LED+

LED-

R7

C8

R8

V

AUX

D5

D4

Figure 13. Flyback Model