1 auxiliary winding configuration, 2 control parameters, 3 output open circuit protection – Cirrus Logic CS1613 User Manual

Page 11

CS1610/11/12/13

DS929F6

11

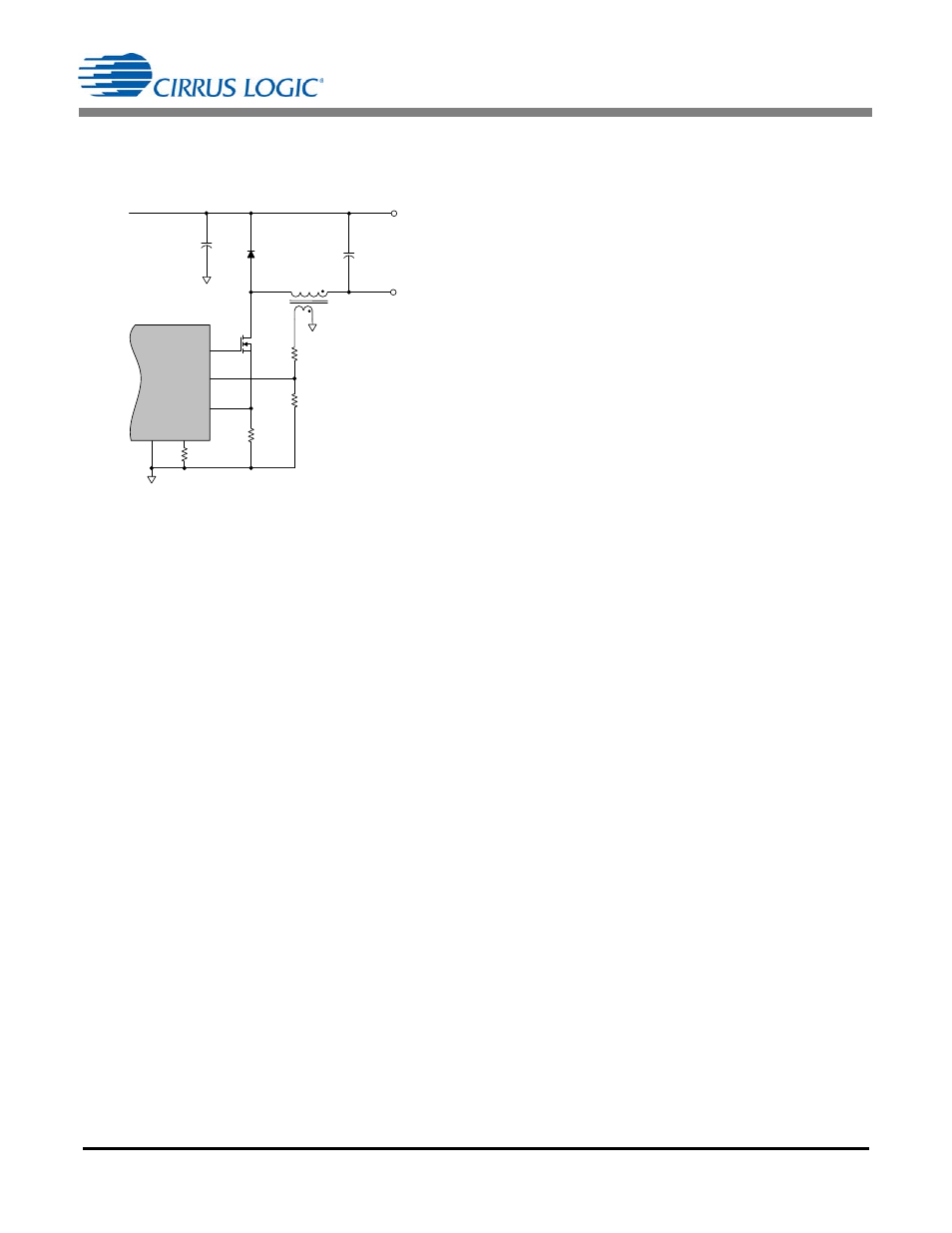

A quasi-resonant buck stage is illustrated in Figure 13. The

buck stage is controlled by measuring current in the buck

inductor and voltage on the auxiliary winding.

The digital buck algorithm ensures monotonic dimming from

2% to 100% of the dimming range with a linear relationship

between the dimming signal and the LED current.

Quasi-resonant operation is achieved by detecting second

stage inductor demagnetization via an auxiliary winding. The

digital control algorithm rejects line-frequency ripple created

on the second stage input by the front-end boost stage,

resulting in the highest possible LED efficiency and long LED

life.

5.7.1

Auxiliary Winding Configuration

The auxiliary winding is also used for zero-current

detection (ZCD) and overvoltage protection (OVP). The

auxiliary winding is sensed through the FBAUX pin of the IC.

5.7.2

Control Parameters

The second stage control parameters assure the following:

• Line Regulation — The LED current remains constant

despite a ±10% AC line voltage variation.

• Effect of Variation in Transformer Magnetizing

Inductance

— The LED current remains constant over

a ±20% variation in magnetizing inductance.

The second stage requires three inputs and generates one

key output. The FBSENSE pin is used to sense the current in

the second stage inductor.

When the current reaches a certain

threshold, the gate drive turns ‘OFF’ (output on pin GD). The

sensed current and the FB

Gain

input are used to determine the

total switching period TT. The zero-current detect input on pin

FBAUX is used to determine the demagnetization period T2.

The controller then uses the total switching period TT to

determine gate turn-on time.

The FB

Gain

input is set using resistor R

FBGAIN

. Resistor

R

FBGAIN

must be selected to ensure that the switching

period TT is greater than the resonant switching period T

critical

at maximum output power. See Equation 5:

where,

T

critical

= resonant switching period at maximum power

T1 = gate turn-on time

T2 = demagnetization time

The total switching period TT is computed for flyback topology

using Equation 6:

where,

= dimming factor, proportional to the duty cycle of the

dimmer, between 0 and 1

I

PK(FB)

= transformer primary winding current

FB

Gain

= constant TT/T2; computed at full load

For buck topology, the total switching period TT is computed

using Equation 7:

where,

= dimming factor, proportional to the duty cycle of the

dimmer, between 0 and 1

I

PK(FB)

= transformer primary winding current

FB

Gain

= constant TT/(T1 + T2); computed at full load

An appropriate value for resistor R

FBGAIN

needs to be

selected to provide the correct gain constant FB

Gain

. Resistor

R

FBGAIN

is calculated using Equation 8:

The value of gain constant FB

Gain

also has a bearing on the

linearity of the dimming factor versus the LED current curve

and must be selected using Application Note AN364: Design

Guide for a CS1610 and CS1611 Dimmer-compatible SSL

Circuit

and AN372: Design Guide for a CS1612 and CS1613

Dimmer-compatible SSL Circuit

.

5.7.3

Output Open Circuit Protection

Output open circuit protection and output overvoltage

protection (OVP) is implemented by monitoring the output

voltage through the transformer auxiliary winding. If the

voltage on the FBAUX pin exceeds the threshold

voltage V

OVP(th)

of 1.25V, a fault condition occurs. The IC

output is disabled, and the controller attempts to restart after

one second.

13

11

R

FB GA IN

FBGAIN

FBAUX

GND

GD

FBSENSE

15

9

12

CS1612/13

R12

R11

R13

Q4

LED +

LED -

V

B S T

C8

D8

C9

L3

Figure 13. Buck Model

TT

T

critical

T1 T2

+

=

[Eq.5]

TT

I

PK FB

T2

FB

Gain

-------------------

[Eq.6]

TT

I

PK FB

T1 T2

+

FB

Gain

-------------------

[Eq.7]

R

FBGAIN

62.5k

FB

Gain

2

1

–

-------------------------------------------

=

[Eq.8]