Pcb layout, 1 power layout recommendations, An346 – Cirrus Logic CS160x User Manual

Page 3

AN346

3

2. PCB LAYOUT

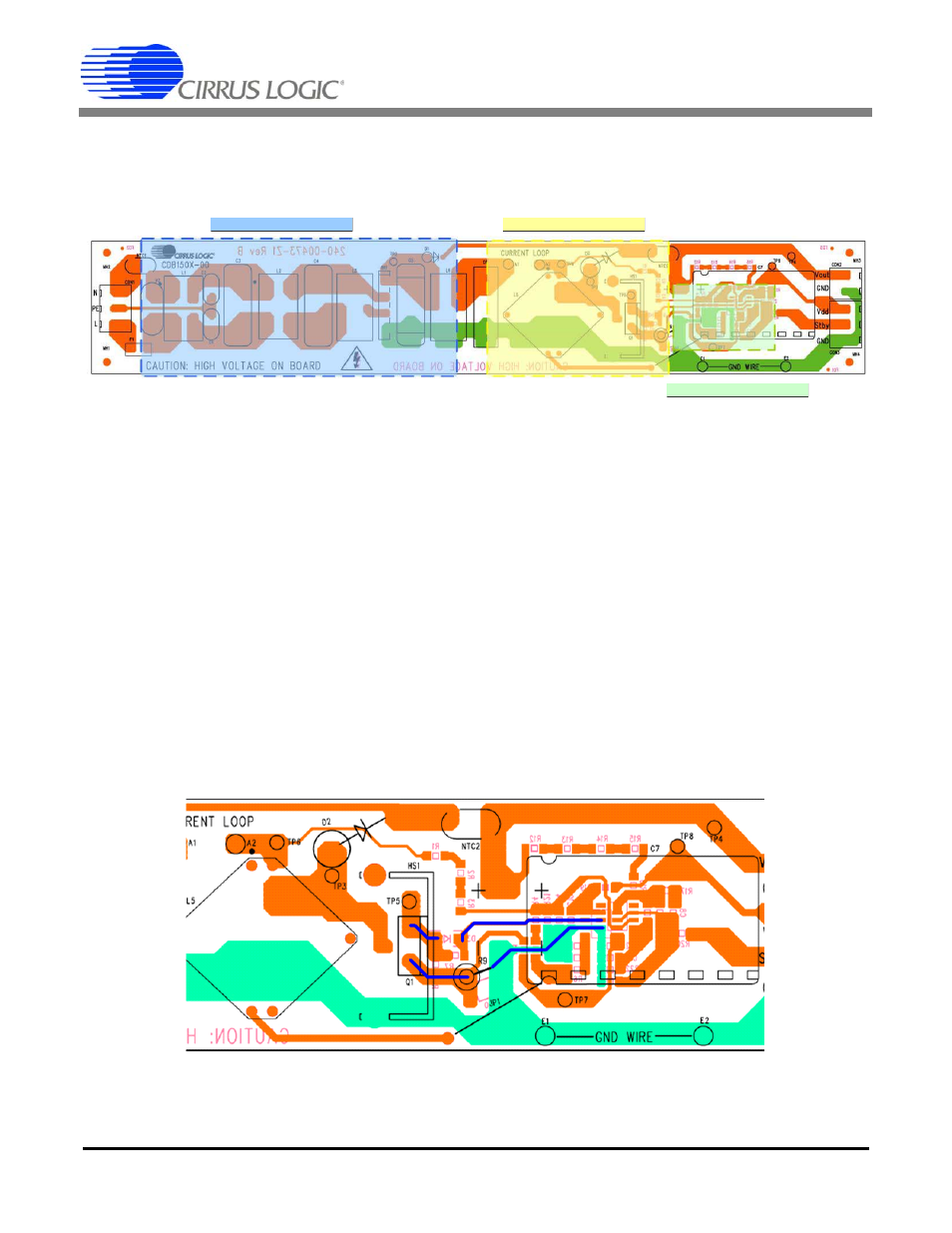

Figure 1 and Figure 2 show a schematic and layout for a 90W PFC stage. The board is a single-layer PCB

with through-hole components on the top side, surface-mount components & signal routing on the bottom.

Figure 2. Single-layer PCB Layout for a 120W PFC-only Application Using the CS1500

The following sections demonstrate the best layout practices when designing a system using the

CS1500/CS1501.

2.1

Power Layout Recommendations

The following are good layout guidelines for a PFC stage or fluorescent ballast.

– Keep the main power components such as inductor, FET, diode, and output bulk capacitor as close

together as possible. Minimize trace impedance by keeping connections as short & wide as

possible. Fast power switching currents generate noise in proportion to the trace impedance.

– The power-stage ground and the signal ground must be separated.

– Input decoupling capacitors should be placed close to the inductor.

– EMI filter should be placed as close to AC inlet as possible.

– The MOSFET gate drive loop length should be minimized, as shown in Figure 3. This applies to

both the positive (drive) path & return (GND).

– Current sense resistor return (GND) should be close to the output bulk capacitor negative (GND)

to reduce interference with the IC.

Figure 3. Gate-to-Ground Current Paths Between CS1501 and MOSFET

EMI Filter

Boost PFC Section

Low Voltage IC Section