Joint connections, Appliance connection, Condensate drains – DuraVent FasNSeal Single-Wall User Manual

Page 7

7

JOINT CONNECTIONS

The female end of each FasNSeal®

component incorporates a sealing gasket

and a mechanical locking band. Examine all

components prior to installation. Gaskets

must be in proper position or flue gases

could leak and result in carbon monoxide

poisoning.

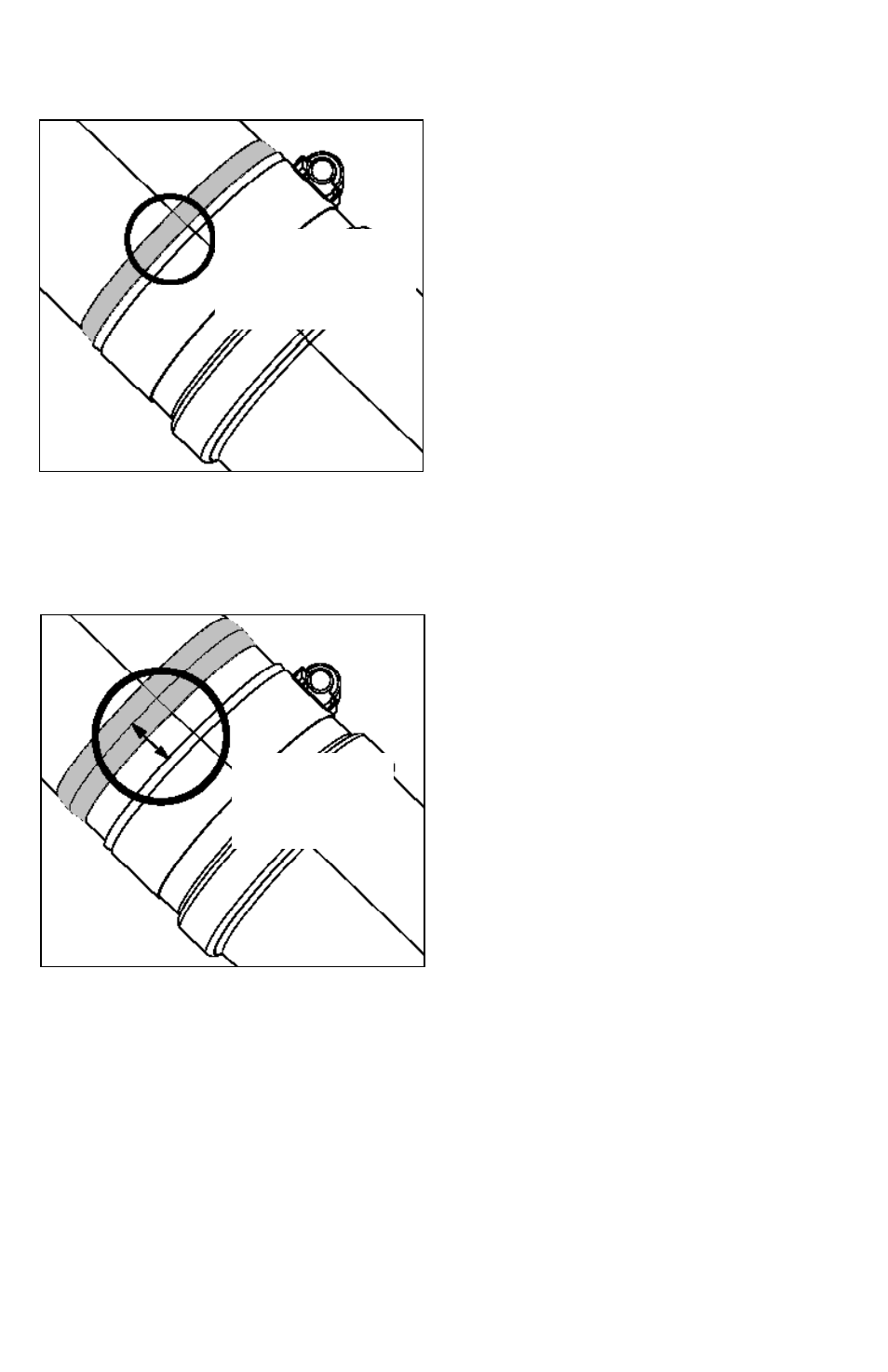

1. Insert the male end into the female

section. Push the units together and turn

them until half of the bead on the male

end is covered by the flared edge of the

female end. (see Figure 2). This creates

the needed airtight seal for Category II, III

or IV appliances. Align the seams on the

vent lengths and orient them upward in all

horizontal applications.

2. Tighten the locking band with a nut driver

until snug plus 1/4 turn.

Before proceeding, recheck all joints and

ensure that all male sections extend to the

top of the flared female end and all clamps

are tightened.

APPLIANCE CONNECTION

Connect FasNSeal® to the appliance

flue collar as directed in the appliance

manufacturer’s instructions. If the appliance

flue collar is not designed to accept FasNSeal®

directly, an adapter may be available.

CONDENSATE DRAINS

If instructions or local regulations call for

a condensate drain, use a FasNSeal® Drain

Fitting (FSDF) and a 5/8” ID plastic tube (3/8”

for the Horizontal Drain Fitting, FSHDT) of

appropriate size to connect the Tee into the

sanitary sewer drain. Always create a siphon

loop in the plastic tube. Follow all local and

national codes for draining acidic effluent. Do

not use copper as a drain as it may corrode.

Correct Joint Connection.

Male/Female sections fully engaged.

INCORRECT Joint Connection.

Male/Female sections

NOT fully engaged.

Figure 2

jOINT CONNECTION IS

CORRECT WHEN HALF OF THE

BEAD ON THE MALE END IS

COVERED By THE FLARED EDGE

OF THE FEMALE END.

CONNECTION IS

INCORRECT IF GAP

IS BETWEEN FLARED

FEMALE EDGE AND TOP

OF BEAD