Figure 10 figure 9 figure 8 – DuraVent FasNSeal Single-Wall User Manual

Page 12

12

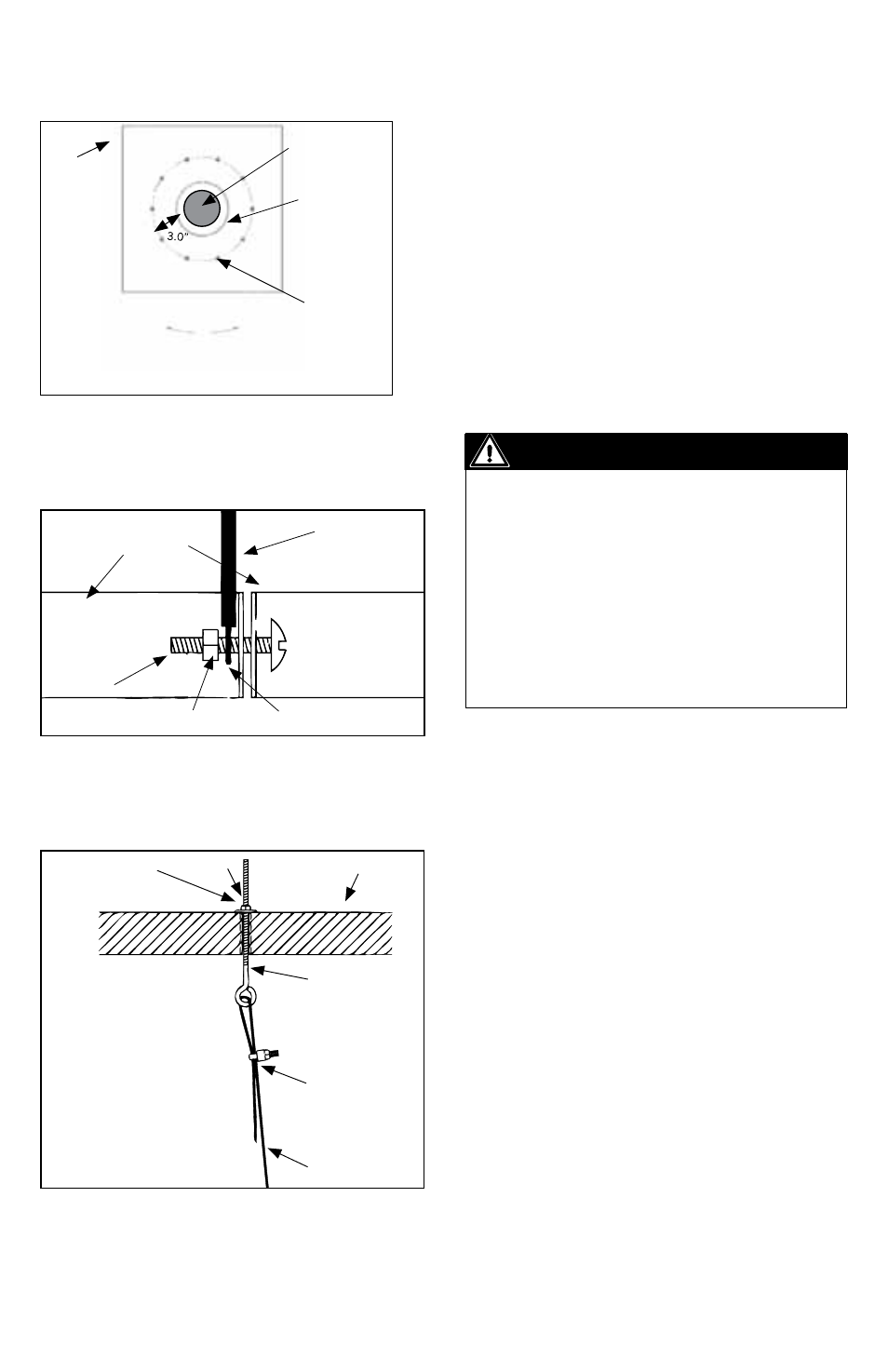

of the vent will provide some lateral stability

to the system. Additional ¼” threaded holes

will have to be drilled around the vent for

the anchors. These smaller holes should

be evenly spaced around the diameter of

the central hole. Refer to Figure 8 for the

recommended pattern.

Install ¼” eye bolts with washers and nuts.

These will be used to anchor the tension

wires to the support plate.

Figure 10

Figure 9

Figure 8

1. Inspect and verify the structural integrity of

the chimney and chimney cap. The weight of

the vent will be resting on the chimney and

an unstable chimney may shift

and/or collapse.

2. Install a FasNSeal support clamp at the

base of the vent stack. The first support

clamp should be located directly below the

upper joint on the bottom most straight vent

length (Figure 7). Refer to Figure 9 for the

proper method of securing tension wires to

the FasNSeal support clamp. Do not fasten

the cable between the clamp half-shells. This

will prevent the clamp from gripping the vent

stack properly

3. Gradually lower the vent stack into the

chimney. Secure additional FasNSeal support

IMPORTANT

The loads, plate and cable thickness,

as well as the eyelet sizes specified in

these instructions are representative

and must be calculated for each

individual application.

Be sure to remember to connect the

condensate drain at the bottom of the

stack. Condensates must be directed to

a safe point of discharge.

DEGREES

BETWEEN HOLES

180° ÷ #CLAMPS

1/4"

HOLES

FASNSEAL

VENT LENGTH

STEEL

PLATE

1/2" HOLE

LARGER THAN

OTER WALL OF

VENT

TENSION WIRE

CLAMP HALFSHELL

EyELET

NUT

SCREW

teNSIoN WIre

CaBle ClaMp

1/4" eye Bolt

Steel plate

WaSher

Nut