Adjustment for cable actuated clutch, Adjustment for hydraulic actuated clutch – Rivera Primo Centri-Force - Brute IV User Manual

Page 3

Place the basket on a sturdy surface and lay the Centri-Force™ pressure plate on the face of the basket with the guide

positioned around the outside edge of the basket. Using masking tape, tape the Centri-Force™ pressure plate in place to

prevent movement. Slide the supplied transfer punch (point side down) into each of the six counterbored attachment holes

found the perimeter of the Centri-Force™ pressure plate and lightly tap with a hammer. Using a good drill press, drill a

small hole with 1/8" pilot drill, 3/4” deep into each of the six indentations made with the transfer punch. Using the supplied

drill bit (PP-418), finish drilling the holes to a depth of 3/4”. Thread the holes using tapping lubricant and the supplied 1/4-

20 tap and then thoroughly clean the drilled & tapped holes with forced air. Press in the clutch hub assembly and reinstall

the snap ring.

Re-install the front pulley, belt & rear pulley (clutch basket), and install the new Centri-Force clutch plates as follows: One

.080" steel drive plate in first, followed by a friction. Alternate steel, friction, ending with a friction plate up against the

Centri-Force™ pressure plate. Do NOT use the .120 steel and be sure to only use the amount of steels and fibers speci-

fied above. In addition, You will NOT use the original pressure plate, diaphragm spring or spring retainer, nuts and lock

tabs. The Centri-Force™ pressure plate assembly replaces those items. Bolt the Centri-Force™ pressure plate onto the

face of the clutch basket with the supplied ¼-20 x ½" bolts into the newly drilled & tapped holes. You are now ready to

adjust the Centri-Force™ pressure plate.

Note: Adjusting the Centri-Force™ pressure plate is relatively easy; however we recommend that it be done by an expe-

rienced motorcycle mechanic.

ADJUSTMENT FOR CABLE ACTUATED CLUTCH

After all the clutch fibers, steel drive plates and Centri-Force™ pressure plate are installed, you must make sure that you

have at least .060 - .070" of clearance. This clearance can be measured by using the extension 'depth' end of a dial caliper.

Insert the extension into the well in the center of the Centri-Force™ pressure plate so the end is contacting the surface of

the pressure plate. Press down on the six external pressure plate springs so that the pressure plate is forced away from

the housing and against the clutch pack, then measure the gap between the surface of the pressure plate and the inside

surface of the housing. (See Figure 3.). If this measurement is not correct, you may need to purchase extra steels to get

to the proper specification.

If you want your motorcycle to idle faster, and you find that the Centri-Force™ pressure plate is engaging to soon, you will

need to get more clearance between the pressure plate and the housing, if you have a slower idle and you need the clutch

to engage quicker you will need less clearance between the pressure plate and the housing.

You can also get the clutch to engage later by adding spring washers to each of the six spring posts, or get the clutch to

engage sooner by removing a spring washer from each of the six spring posts.

Take all the adjustment out of the clutch cable so that the clutch lever is up against the handlebar grip. Turn the center

clutch adjusting screw in until you see the clutch lever just start to move away from the handlebar grip, then lock down the

clutch adjustment screw jam-nut tightly. The clutch is now adjusted and ready for operation.

ADJUSTMENT FOR HYDRAULIC ACTUATED CLUTCH

After all the clutch fibers, steel drive plates and Centri-Force™ pressure plate are installed, you must make sure that you

have at least .060 - .070" of clearance. This clearance can be measured by using the extension 'depth' end of a dial caliper.

Insert the extension into the well in the center of the Centri-Force™ pressure plate so the end is contacting the surface of

the pressure plate. Press down on the six external pressure plate springs so that the pressure plate is forced away from

the housing and against the clutch pack, then measure the gap between the surface of the pressure plate and the inside

surface of the housing. (See Figure 3.). If this measurement is not correct, you may need to purchase extra steels to get

to the proper specification.

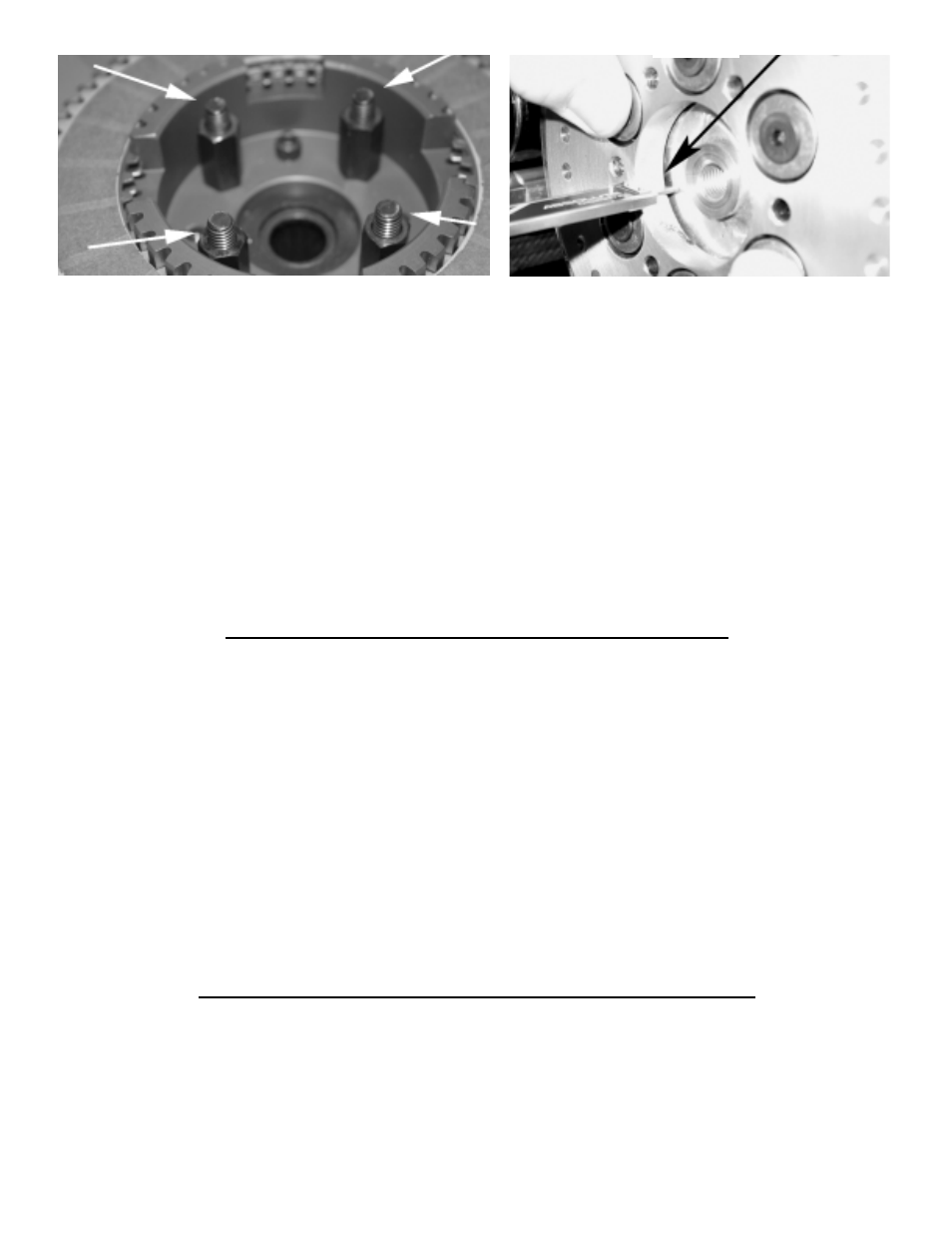

Figure 2

Figure 3

3