Adjustment for hydraulic actuated clutch, Disassembly & assembly, Operation – Rivera Primo Centri-Force - Brute IV Extreme User Manual

Page 2

You can also get the clutch to engage later by adding spring washers to each of the six spring posts, or get the clutch to

engage sooner by removing a spring washer from each of the six spring posts.

Take all the adjustment out of the clutch cable so that the clutch lever is up against the handlebar grip. Turn the center

clutch adjusting screw in until you see the clutch lever just start to move away from the handlebar grip, then lock down the

clutch adjustment screw jam-nut tightly. The clutch is now adjusted and ready for operation.

ADJUSTMENT FOR HYDRAULIC ACTUATED CLUTCH

After all the clutch fibers, steel drive plates and Centri-Force™ pressure plate are installed, you must make sure that you

have at least .060 - .070" of clearance. This clearance can be measured by using the extension 'depth' end of a dial caliper.

Insert the extension into the well in the center of the Centri-Force™ pressure plate so the end is contacting the surface of

the pressure plate. Press down on the six external pressure plate springs so that the pressure plate is forced away from

the housing and against the clutch pack, then measure the gap between the surface of the pressure plate and the inside

surface of the housing. (See Figure 3.). If this measurement is not correct, you may need to purchase extra steels to get

to the proper specification.

If you want your motorcycle to idle faster, and you find that the Centri-Force™ pressure plate is engaging to soon, you will

need to get more clearance between the pressure plate and the housing, if you have a slower idle and you need the clutch

to engage quicker you will need less clearance between the pressure plate and the housing.

You can also get the clutch to engage later by adding spring washers to each of the six spring posts, or get the clutch to

engage sooner by removing a spring washer from each of the six spring posts.

To bleed the clutch hydraulic actuator unit, turn the center adjustment screw until it bottoms out the slave cylinder piston,

then turn out the center adjustment screw 2 to 2 ½ turns only. This will prevent the slave cylinder piston from popping out

of the bore.

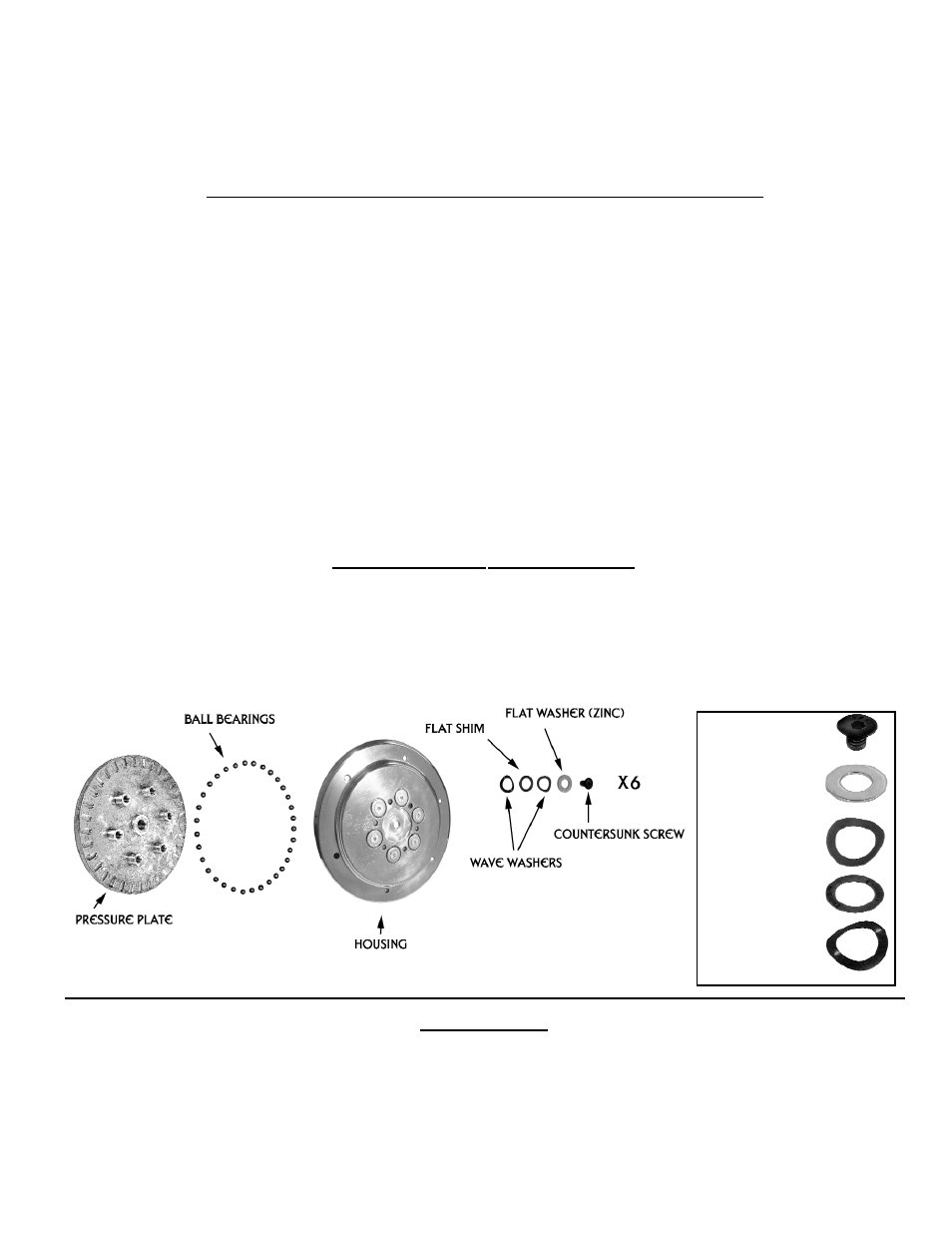

DISASSEMBLY & ASSEMBLY

Remove the six bolts from the Centri-Force™ pressure plate housing. Under each countersunk bolt are a large zinc plat-

ed flat washer, 2 spring washers and 1 shim . Carefully remove Centri-Force™ housing from the pressure plate to expose

the 30 ball bearings. Assemble in reverse; DO NOT use thread lock on the 6 bolts. Prior to completing assembly, the hous-

ing and the pressure plate must be indexed. On the back side of the pressure plate there is a small thru hole. On the back

side of the housing there is a small dimple. Line the dimple on the housing with the thru hole on the pressure plate and

then complete assembly. (See Figure 2).

OPERATION

CAUTION:

Always put the motorcycle in NEUTRAL before starting the motorcycle, and when coming to a complete stop. Although it

is possible to start the bike when in gear and to idle in gear without utilizing the clutch lever, it is dangerous and could result

in injury to person or damage to motorcycle. Always pull in the clutch lever when coming to a stop and when at a stand

still. To shift the motorcycle during operation, simply unload the Centri-Force

™

actuated clutch by coming completely off

the throttle, complete the shift, then throttle back up. The Centri-Force™ pressure plate allows you to accelerate slowly or

hard without effort and clutch pull is dramatically reduced or eliminated, making it the perfect solution for riders who find it

difficult to pull in their clutch lever.

screw

zinc washer

wave spring

facing down

middle shim

wave spring

facing up

ASSEMBLY ORDER

Figure 2