Bearing fits and tolerances, Reassembly, Assemble the column and support plate – Goulds Pumps API 3171 - IOM User Manual

Page 51: Eassembly, Bearing fits and, Tolerances

• Inspect bearing shell (134) bore according to the dimensions in the Bearing fits and tolerances -

Thrust bearing fits table. Replace if dimensions exceed these values.

• Replace the lower grease seal (133) at every overhaul.

• Visually inspect for cracks and pits. Pay particular attention to the snap ring groove.

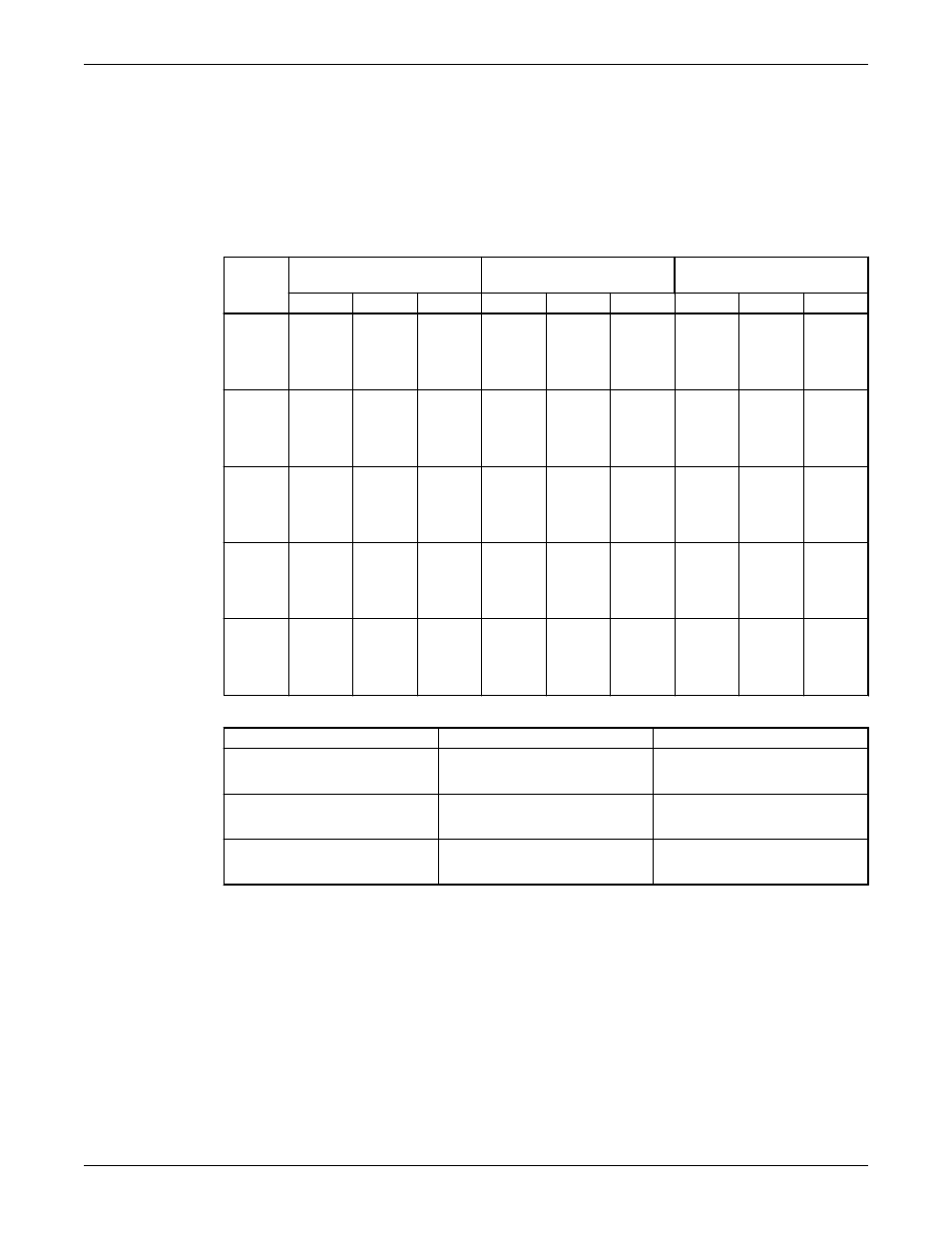

Bearing fits and tolerances

This table references the bearing fits and tolerances according to ISO 286 (ANSI/ABMA Standard 7) in

inches (millimeters).

Table 5: Steady bearing tolerances

Descript

ion

Bearing ID (pressed into

place)

Housing bore

Running clearance (1/2

diametrical clearance)

S/ST

M/MT L

S/ST

M/MT L

S/ST

M/MT L

Carbon

1.132–

1.134

(28.753–

28.804)

1.633–

1.635

(41.478–

41.529)

2.258–

2.260

(57.353–

57.404)

1.621–

1.623

(41.173–

41.224)

2.121–

2.123

(53.873–

53.924)

2.994–

2.996

(76.048–

76.098)

0.0055–

0.0035

(0.140–

0.089)

0.006–

0.004

(0.152–

0.102)

0.0065–

0.004

(0.165–

0.102)

Bronze

1.129–

1.131

(28.677–

28.727)

1.629–

1.631

41.377–

41.427

2.256–

2.258

(57.302–

57.353)

1.621–

1.623

(41.173–

41.224)

2.121–

2.123

(53.873–

53.924)

2.994–

2.996

(76.048–

76.098)

0.004–

0.002

(0.102–

1.051)

0.004–

0.002

(0.102–

1.051)

0.0055–

0.003

(0.140–

0.076)

Fluted

elastomer

1.126–

1.130

(28.600–

28.702)

1.627–

1.632

(41.326–

41.453)

2.253–

2.257

(57.226–

57.328)

1.621–

1.623

(41.173–

41.224)

2.121–

2.123

(53.873–

53.924)

2.994–

2.996

(76.048–

76.098)

0.0035–

0.0005

(0.089–

0.013)

0.0045–

0.001

(0.114–

0.025)

0.005–

0.004

(0.127–

0.102)

Rulon

1.132–

1.134

(28.753–

28.804)

1.633–

1.635

(41.478–

41.529)

2.258–

2.260

(57.353–

57.404)

-

-

-

0.0055–

0.0035

(0.140–

0.089)

0.006–

0.004

(0.152–

0.102)

0.0065–

0.004

(0.165–

0.102)

Casing

collar

1.183–

1.190

(30.048–

30.226)

1.678–

1.685

(42.621–

42.799)

2.299–

2.306

(58.395–

58.472)

1.811–

1.816

(45.999–

46.126)

2.243–

2.245

(56.972–

57.023)

3.243–

3.245

(82.372–

82.423)

0.0335–

0.029

(0.851–

0.737)

0.031–

0.0265

(0.787–

0.673)

0.029–

0.0245

(0.737–

0.622)

Table 6: Thrust bearing fits

Group

Shaft OD

Shell ID

S/ST

0.9848/0.9844

(25.0139/25.0038)

2.4416/2.4409

(62.0166/61.9989)

M/MT

1.5755/1.5749

(40.0177/40.0025)

3.5442/3.5433

(90.0227/89.9998)

L

2.1660/2.1655

(55.0164/55.0037)

4.7253/4.7240

(120.0226/119.9896)

Shaft runout tolerances

The following shaft runout tolerances apply to all size groups:

• Coupling end: 0.002 in. (0.051 mm)

• Shaft body: 0.0005 in./ft.

• Impeller end: 0.005 in. (0.127 mm)

Reassembly

Assemble the column and support plate

1. If you use the optional stuffing box, then attach the stuffing box (221) to support plate (189) with

bolts (370L).

Maintenance

Model API 3171 Installation, Operation, and Maintenance Manual

49