Pump location guidelines, Concrete foundation requirements – Goulds Pumps API 3171 - IOM User Manual

Page 20

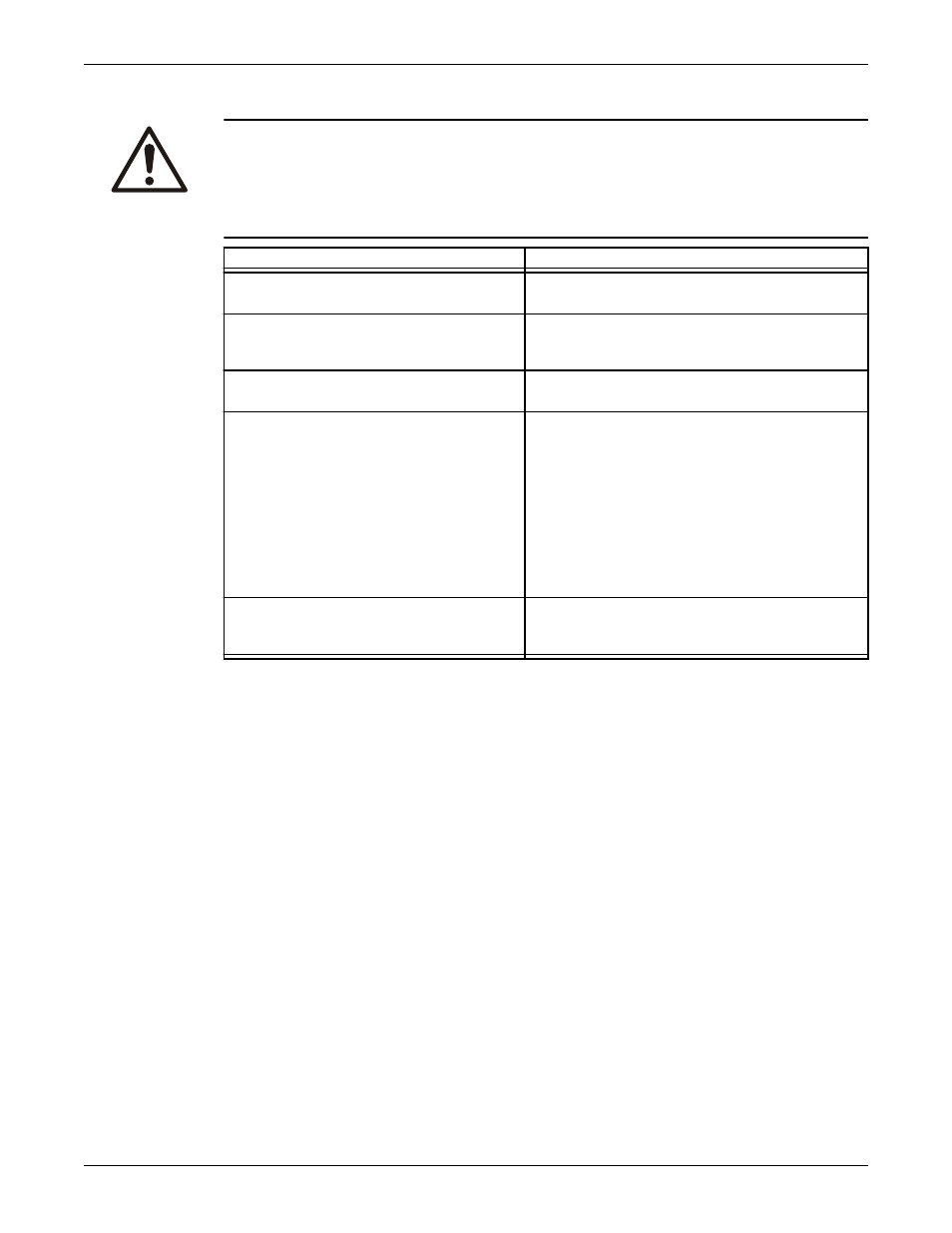

Pump location guidelines

WARNING:

Assembled units and their components are heavy. Failure to properly lift and support this equipment can

result in serious physical injury and/or equipment damage. Lift equipment only at the specifically identified

lifting points. Lifting devices such as eyebolts, slings, and spreaders must be rated, selected, and used for

the entire load being lifted.

Guideline

Explanation/comment

Make sure that the space around the pump is

sufficient.

This facilitates ventilation, inspection, maintenance, and

service.

If you require lifting equipment such as a hoist

or tackle, make sure that there is enough space

above the pump.

This makes it easier to properly use the lifting

equipment and safely remove and relocate the

components to a safe location.

Protect the unit from weather and water damage

due to rain, flooding, and freezing temperatures.

This is applicable if nothing else is specified.

Do not install and operate the equipment in

closed systems unless the system is constructed

with properly-sized safety devices and control

devices.

Acceptable devices:

• Pressure relief valves

• Compression tanks

• Pressure controls

• Temperature controls

• Flow controls

If the system does not include these devices, consult the

engineer or architect in charge before you operate the

pump.

Take into consideration the occurrence of

unwanted noise and vibration.

The best pump location for noise and vibration

absorption is on a concrete floor with subsoil

underneath.

Concrete foundation requirements

Requirements

Make sure that you meet these requirements when you prepare the pump foundation:

• The foundation must be able to absorb any vibration.

• The foundation must be able to form a permanent and rigid support for the pumping unit.

• The foundation must be of adequate strength in order to support the complete weight of the pump

and driver, plus the weight of the liquid that passes through it.

• There should be at least 0.5 in.(12.7 mm) clearance between the sides of the pump and any portion of

the pit.

Typical installation

A typical installation has these characteristics:

• Bolts with a pipe sleeve that is two and a half times the size of the bolt diameter embedded in the

concrete

• Properly sized

• Located in accordance with the dimensions given in the example drawing

• Enough space inside the pipe sleeves to allow the final position of the foundation bolts to align with

the holes in the sub-base flange

Installation

18

Model API 3171 Installation, Operation, and Maintenance Manual