Reassembly of pump l – Goulds Pumps 3500XD - IOM User Manual

Page 40

36

3500XD IOM 8/07

REASSEMBLY OF PUMP

l

!

CAUTION

Wear insulated gloves when using a bearing heater.

Bearings will get hot and can cause physical injury.

This procedure covers reassembly of the pump after complete

disassembly. Be sure all directions in the Inspection and

Overhaul section have been followed.

NOTE: There are several methods used to install

bearings. The recommended method is to use an

induction heater that heats as well as demagnetizes the

bearings.

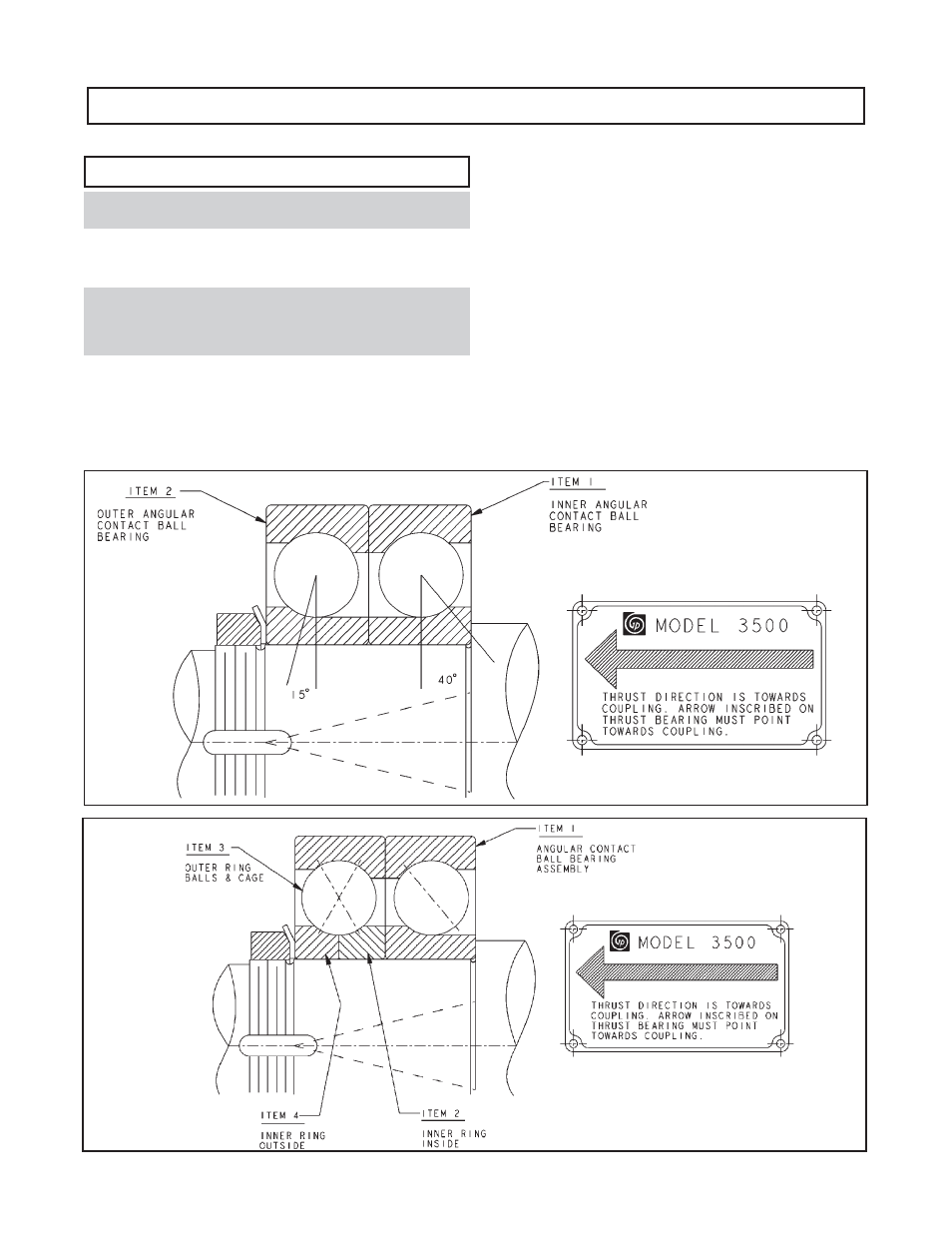

Installation of Thrust Bearings

The Model 3500XD utilizes a thrust bearing on the coupling

end of the shaft designed for high unidirectional thrust loads.

It is thus critical that the thrust bearing be installed in the

proper orientation. The “S” and “L” group pumps utilize a

four point contact bearing paired with a standard angular

contact bearing. The “M” group pump utilizes a Pumpac pair

of bearings. Refer to bearing chart in Figure 20 for detailed

bearing designations.

Both types of thrust bearings consist of a matched pair of

bearings with an arrow scribed on the outer races (see

Figures 22 & 23). The arrow must point in the direction of

axial thrust (i.e. towards the coupling end of the shaft). An

arrow attached to the top of the bearing frame (Figures 22 &

23) shows the correct thrust direction.

Fig. 22

Model 3500XD

M Group

Fig. 23

Model 3500XD

S and L Groups