Maintenance, Lubrication – Goulds Pumps 3500XD - IOM User Manual

Page 33

3500XD IOM 8/07

29

MAINTENANCE

LUBRICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

IMPELLER CLEARANCE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 30

DISASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

INSPECTION AND OVERHAUL. . . . . . . . . . . . . . . . . . . . . . . . . . 35

REASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

LUBRICATION

NOTE: Operation of the unit without proper lubrication

will cause bearing failure, and pump seizure.

NOTE: Pumps are shipped without oil. Oil lubricated

bearings must be lubricated at the job site.

Oil lubricated bearings must be lubricated at the job site.

Remove fill plug and add oil until level is at the center of the

sight glass. Replace fill plug.

Change the oil after 2000 hours for new bearings, thereafter

every 2000 operating hours or 3 months (whichever comes

first). Change more often if oil becomes contaminated with

dirt or water.

A high quality turbine oil with rust and oxidation inhibitors

should be used. For the majority of operational conditions,

bearing temperatures will run between 60° C (140° F) and

82° C (180° F). In this range, an oil of ISO viscosity grade

68 at 40° C (105° F) is recommended. If bearing

temperatures exceed 82° C (180° F), use of ISO viscosity

grade 100 is recommended.

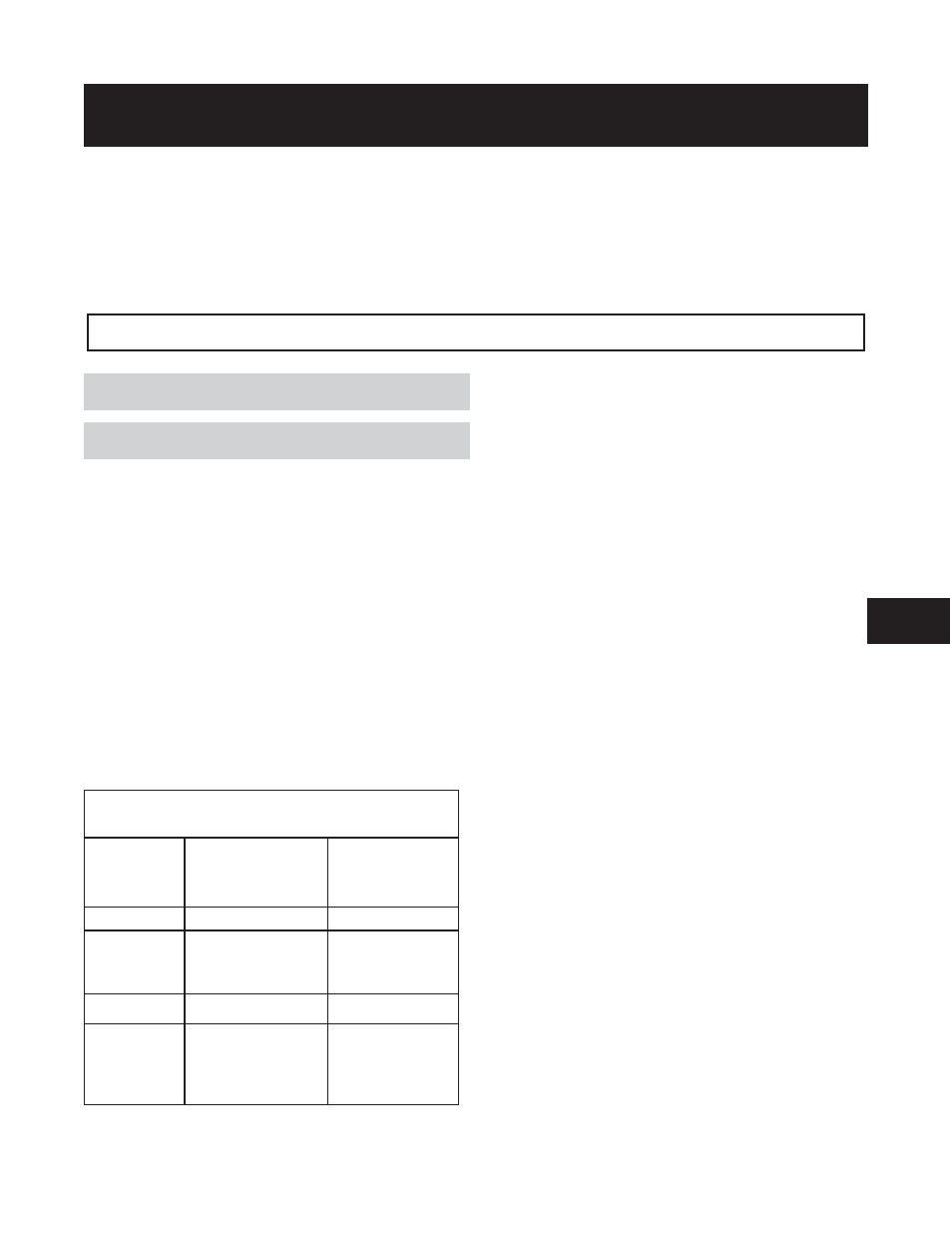

Table 4

Lubricating Oil Requirements

Bearing

Temperature

below 82°

C (180° F)

Bearing

Temperature

above 82° C

(180° F)

ISO Grade

VG 68

VG 100

Approx.

SSU at 38°

C (100° F)

300

470

DIN 51517

C68

C100

Kinematic

viscosity at

40° C (105°

F) mm2/sec

68

100

Acceptable Oils

Exxon

Teresstic EP 68

Chevron

GTS Oil 68

Mobil

Mobil DTE 26 300 SSU

@ 38° C (100° F)

Gulf

Gulf Harmony 68

Phillips

Magnus Oil Grade 315

Phillips

MM motor oil SAE 20-20W

Phillips

HDS motor oil SAE 20-20W

6