Caution – Goulds Pumps 3500XD - IOM User Manual

Page 36

32

3500XD IOM 8/07

unbolting. Carefully slide the gland off the gland studs

and move back on shaft and shaft sleeve. Avoid contact

with exposed lapped seal faces and keep them clean.

NOTE: Mechanical seal parts may be damaged if they or

adjacent parts are handled improperly.

11. Remove the adapter to bearing frame bolts (370B) and

pull the adapter and stuffing box cover as an assembly.

Do not allow the stuffing box cover to strike the shaft,

shaft sleeve, or any mechanical seal part.

12. A cartridge mechanical seal is standard. Position and

tighten the centering tabs and loosen the drive collar set

screws. The cartridge seal can then be removed as a

unit.

13. Scribe shaft at coupling hub for proper positioning of

hub during reassembly and remove hub.

To disassemble remainder of the liquid end, casing and

suction sideplate, proceed as follows:

14. Disconnect suction and discharge flanges.

15. Remove casing hold-down bolts and move casing toward

driver. If preferred, casing can be removed from

baseplate for further disassembly.

16. Remove suction sideplates nuts (423A).

17. Remove suction sideplate (176) by tightening the three

jacking screws (370L). Be careful not to damage the

suction sideplate o-ring (412C).

To complete disassembly of power end proceed as follows:

NOTE: Bearing replacement is recommended whenever

bearings are removed from the shaft.

NOTE: Never use a hammer to drive shaft through

bearings. Severe shaft and bearing damage may occur.

18. Remove the bolts (370B) which hold the frame adapter

to the bearing frame. Remove the frame adapter (108).

19. Remove the bolts (360) which hold the inboard bearing

end cover to the frame. Remove the end cover (119A)

and labyrinth seal (125).

20. Remove bearing housing bolts (370C). Impeller

adjustment bolts with jam nuts (370D) can be used to

assist in the removal of the shaft and bearing assembly

from the bearing frame.

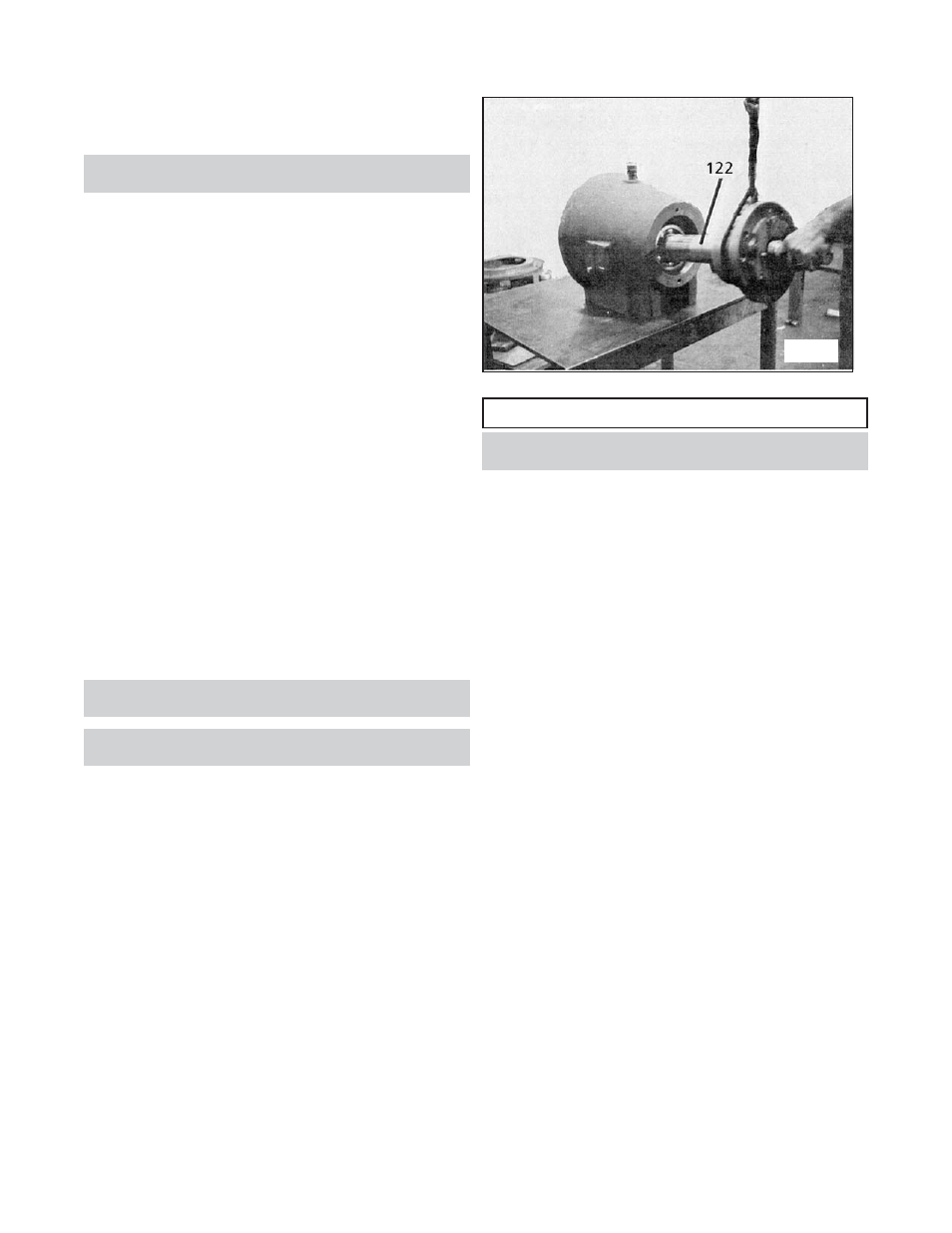

21. Slide the complete shaft assembly from back end of

bearing frame. (See Fig. 19) This includes the shaft,

both bearings (radial and thrust), and bearing housing.

Do not lose or damage bearing housing o-ring.

l

!

CAUTION

Wear insulated gloves when using a bearing heater.

Bearings will get hot and can cause physical injury.

22. Using a bearing puller or a press, remove the inboard

cylindrical roller bearing (409). Be sure to apply the

removing force to the inner race of the bearing to prevent

damage to the races.

23. Be sure shaft and keyway are free of burrs and sharp

edges so labyrinth seal o-ring will not be damaged and

remove bearing end cover (109A).

24. Slide the bearing housing (134A) off shaft.

25. Straighten “tang” in lock washer (382) and remove

bearing lock nut and washer.

26. Remove coupling end bearing using a bearing puller.

Care must be taken to prevent damage to bearings.

NEVER USE A HAMMER TO DRIVE SHAFT

THROUGH BEARING. Protect bearing from

contamination.

27. The “L” group shaft is equipped with two oil flingers

(236). If the shaft is being re-used, the flingers should

not be removed, as they may be deformed during

removal. If the shaft is being replaced, new flingers

should be used.

Fig. 19