Goulds Pumps 3500XD - IOM User Manual

Page 32

28

3500XD IOM 8/07

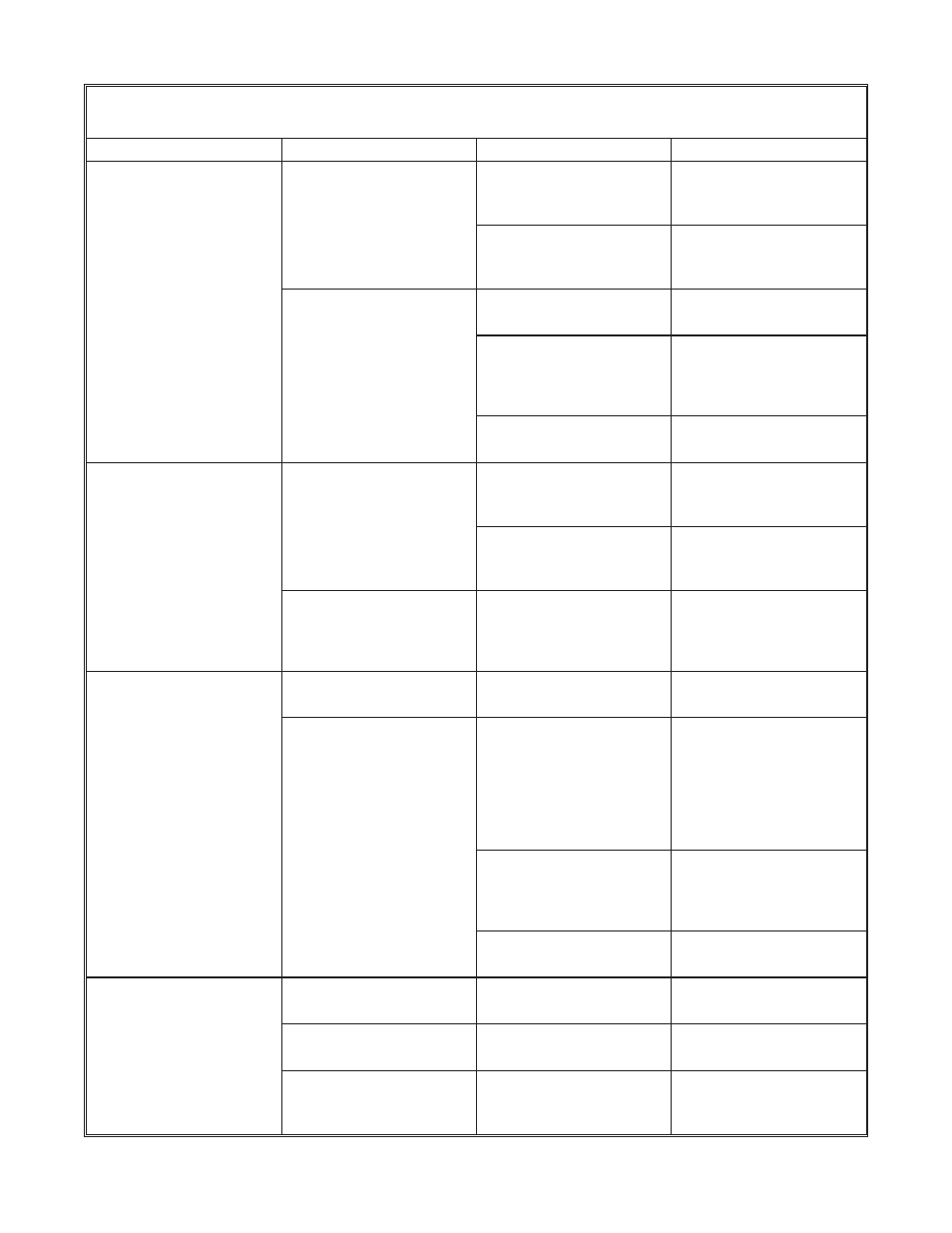

Table 3

TROUBLESHOOTING THE MODEL 3500XD STANDPIPE INSTALLATION

PROBLEM

SYMPTOMS

POSSIBLE CAUSE

SOLUTIONS

Pump will not start pumping

Amps to drive motor normal

Control valve LCV does not

open

Check that the supply air

pressure to the actuator is

sufficient

Discharge pipe plugged

Open by flushing, check

that any manual valves in

the discharge pipe are open

Amps to drive motor below

normal

ARV has not opened

Open manually and check

setting on LCV limit switch

Pressure in air removal

piping too high

Check that the vacuum

pump is running and the

setting of the vacuum relief

valve

Air removal pipe plugged

with stock

Flush air removal piping

Pump discharge flow too low

Level control valve 100%

open

Standpipe dilution valve not

operating, or dilution water`

pressure too low

Check that dilution valve is

operating, check dilution

water pressure

Flow too high compared to

pump capacity

Check pump and motor

speed, check V belts if V

belt driven

Pump power consumption

and air removal pressure

unstable

Level in standpipe too low,

or air removal pressure too

high

Raise the level set point in

the standpipe, or reduce

pressure in air removal

piping

Stock discharge pipe vibrates

Power consumption and air

removal pipe pressure stable

Discharge piping

inadequately supported

Improve discharge pipe

supports and anchors

Power consumption and air

removal vacuum unstable

Stock in the standpipe has

large voids, or the

consistency is too high

Make sure that stock

delivered to the standpipe is

well shredded. Dilute if

necessary by adding

dilution at the shredder

screw and to the upper part

of standpipe.

The signal to the level

control valve is unstable

Check the valve movement,

delay the input from the

level transmitter if

necessary

Level measurement is too

sensitive

Add filtering, or delay the

input to the LIC

Motor overloaded

Motor overloaded

Volume flow above normal

Consistency is too low,

switch to manual control

Flow unstable

Power consumption normal

Flow transmitter is too

sensitive

Increase transmitter

response time

Power consumption normal

but changes with the level

control valve opening

Control not working

properly

Recalibrate or adjust

controller