Inspection and overhaul, Table 6 bearing designation vs pump size and group – Goulds Pumps 3500XD - IOM User Manual

Page 39

3500XD IOM 8/07

35

INSPECTION AND OVERHAUL

Impeller and Repeller

Replace if impeller, X-Ducer nut, or repeller show excessive

erosion, corrosion, extreme wear or vane breakage. O-ring

grooves must be in good condition. Check condition of

bores, as fit on shaft is critical (0.0010 to 0.0025” clearance

standard). Check impeller balance if possible (max.

unbalance of 3.6 in-oz. standard).

Inducer and Centrifuge

Replace if they show excessive erosion, corrosion, or

bent/broken vanes. Check condition of o-ring grooves.

Suction Sideplate

Replace if sideplate shows excessive metal loss due to

corrosion, erosion or wear.

Shaft

Check for runout to see that the shaft is not bent. Bearing

seats and labyrinth seal areas must be in perfect condition and

free of scratches and grooves. O.D. and finish in these areas

must be within bearing manufacturer’s specifications. Check

that the keyway is free of corrosion. Replace shaft if

necessary.

Shaft Sleeve

The shaft sleeve is a push fit and is bored 0.001” to 0.003”

larger than the shaft and should tap easily on the shaft. If the

sleeve does not tap on easily, the bore and shaft should be

inspected to see that they are free from foreign matter or

burrs. The fit of the key in the keyway should also be

checked to see that it is not causing binding. The key should

have a sliding fit on the sides and should have clearance at

the top. Sleeve surface in stuffing box must be smooth and

free of grooves. If grooved, replace. O-ring groove must be

in good condition. The original diametrical clearance

between shaft sleeve and stuffing box bore is 0.025” to

0.032”. If this clearance has increased to more than 0.050”,

the shaft sleeve, and at times the stuffing box, should be

replaced.

Mechanical Seal

Lapped seal faces, gaskets, and shaft sealing members must

be in perfect condition or excessive leakage may result.

Replace worn or damaged parts.

Ball Bearings

Replace if worn, loose, rough or noisy when rotated.

Replacement bearings must be of the proper size and type as

specified in the construction details (Table 6).

Labyrinth Oil Seals

Inspect and replace if o-rings are torn or otherwise damaged.

General

All parts should be clean before assembly. This is especially

important at O-ring grooves, threads, lock fits, gasket

surfaces and bearing areas. Any burrs should be removed

with crocus cloth. Replace all gaskets and o-rings when

maintenance is performed.

6

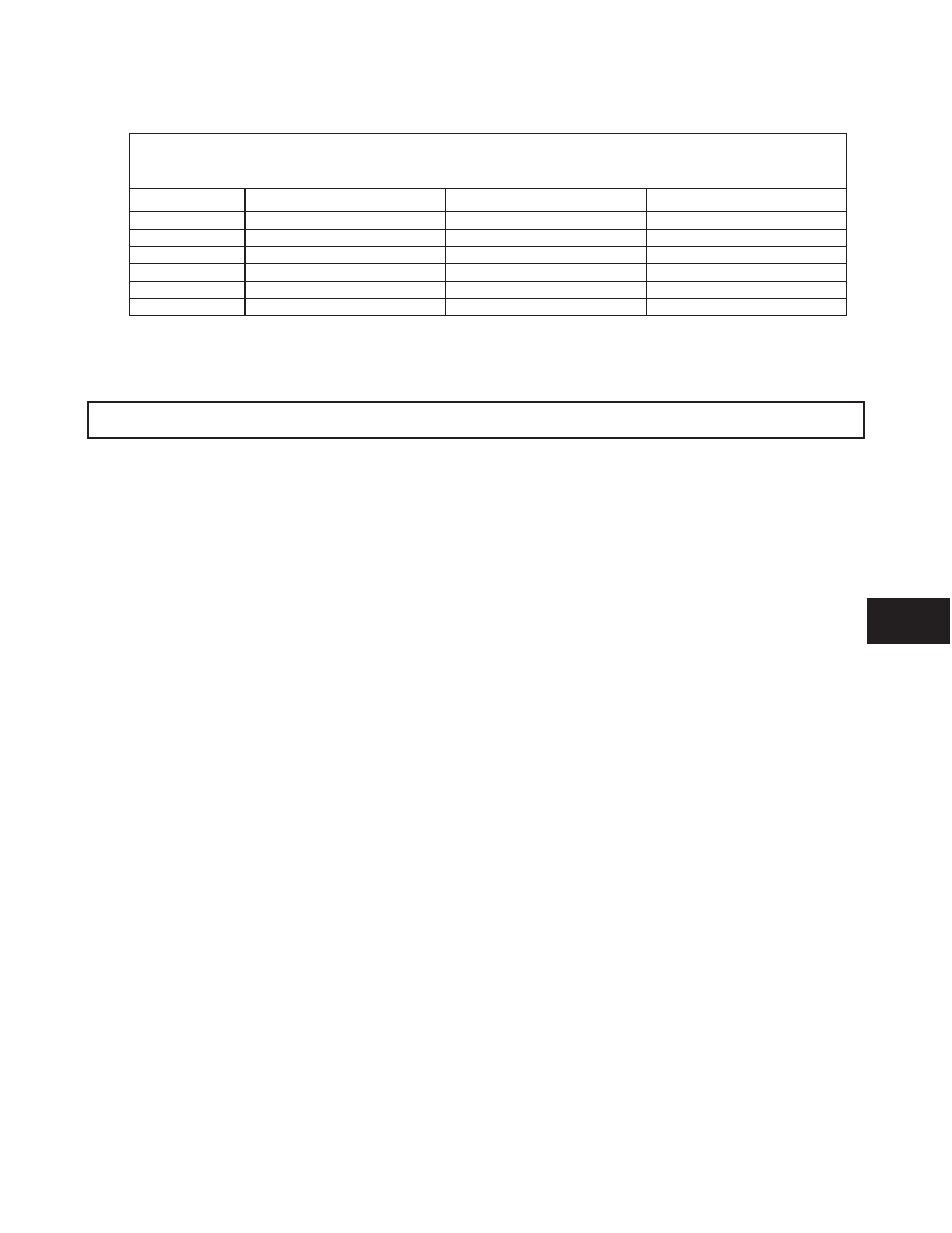

Table 6

BEARING DESIGNATION VS PUMP SIZE AND GROUP

Pump Size

Group

Thrust Bearing

Radial Bearing

3x6-14XD

S

SKF BA2B459313

SKF NUP-313ECP

4x8-18HXD

M

SKF 8317

SKF NUP-317ECP

6x10-18

M

SKF 8317

SKF NUP-317ECP

6x10-22HXD

M

SKF 8317

SKF NUP-317ECP

4x8-24

XD

L

SKF BA24B459422

SKF NUP-222ECP

6x12-24XD

L

SKF BA24B459422

SKF NUP-222ECP