Goulds Pumps 3311 - IOM User Manual

Page 9

9

Determining the strainer pressure loss

Example:

Feed line = DN 125

Flow rate 80 m³/h

ζ = 4

v = 1.81 m/s in the feed line

Hv =

66

.

0

62

.

19

276

.

3

4

81

.

9

2

81

.

1

4

2

=

•

=

•

•

m

The suction line must be leak-proof and it must be

possible to release all air. The suction opening of the

suction line should be well below the liquid level, and a

foot valve with a strainer should be used. The foot valve

must be far enough from the bottom to avoid excessive

inlet losses which could impair performance.

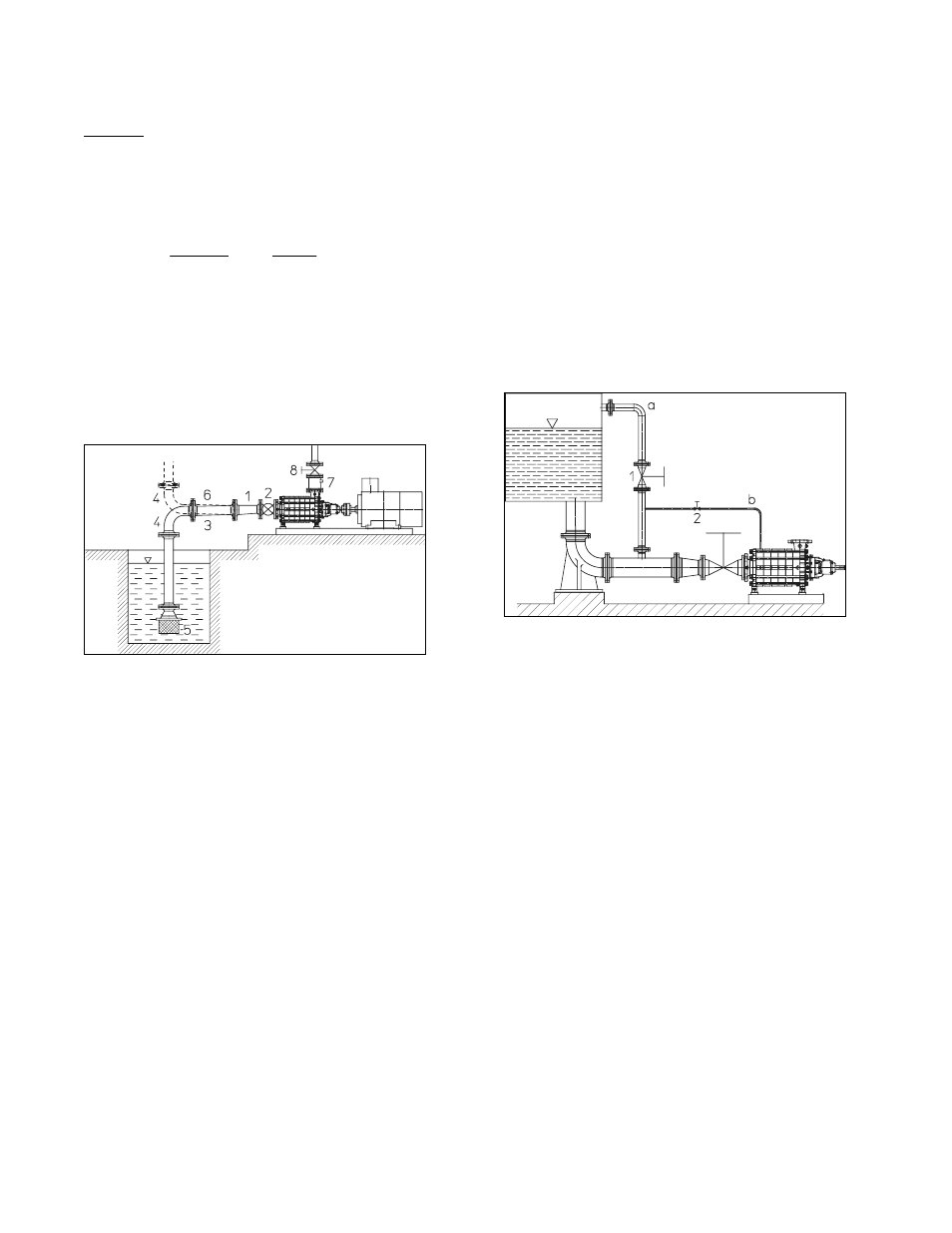

1 Eccentric reducer (suction operation) or

concentric reducer (feed operation)

2 Shut-off valve

3 Suction line

4 Bend

5 Foot valve

6 Feed line

7 Non-return valve

8 Control valve

Pump installation

A shut-off valve should be installed in the feed line; it is

to be closed for maintenance work.

It should be installed such that air pockets cannot form in

the spindle cap, i.e. with the spindle in a horizontal

position or pointing vertically downward.

3.1.3 Vacuum equalizing pipe

If the pump draws from a system or tank under vacuum,

an equalizing pipe must be installed connecting the vent

connection at the suction casing or the highest point of the

suction line to a point above the maximum liquid level in

the suction tank.

- The line should be fitted with a shut-off valve which

should only be closed for maintenance work on the

pump.

To assist in starting the pump, we also recommend that a

pipeline, which can be shut off, be installed between the

first stage and the equalizing line.

a Equalizing line

b Additional line

1 Shut-off valve

2 Shut-off valve (vacuum-tight)

Vacuum operation

3.1.4 Discharge line

For flow control, install a shut-off valve as close to the

pump nozzle as possible. It is recommended that a non-

return valve be installed between pump nozzle and shut-

off valve, thus protecting the pump against reverse

rotation and also the pump and the foot valve against

water hammer that may occur in the event of sudden shut-

down.