Goulds Pumps 3311 - IOM User Manual

Page 22

22

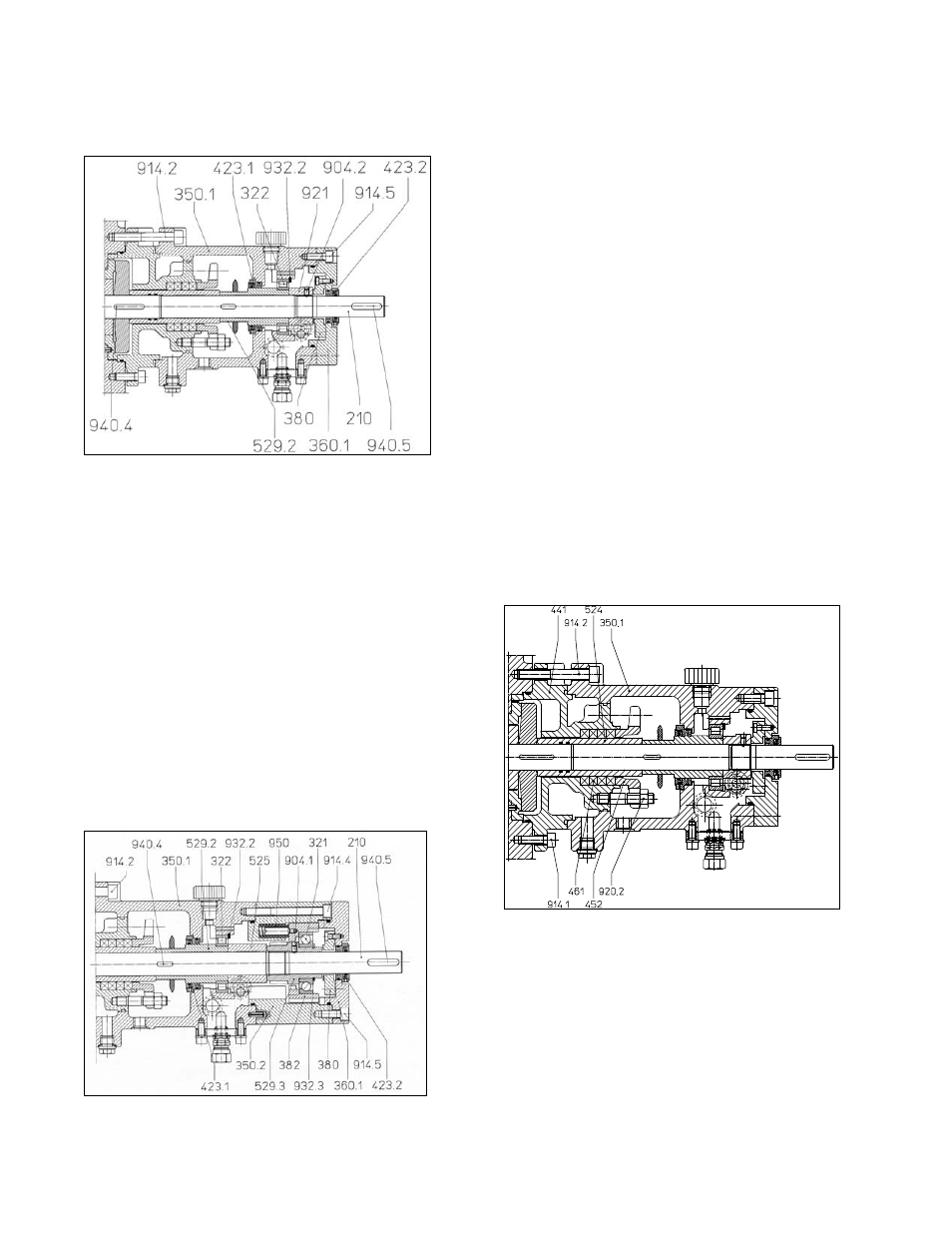

b) Anti-friction

bearing,

- oil-lubricated – drive side

- without lift-off device -

- If installed - remove cooling and/or circulation line

- Remove key 940.5

- Release bolts 914.5

- Remove bearing cover 360.1 with labyrinth ring 423.2

and limiting ring 380

- Release grub screw 904.2

- Remove circlip 932.2

- Support shaft 210 and key 940.5, and release shaft nut

921

- Release bolts 914.2

- Withdraw bearing housing 350.1, labyrinth ring 423.1,

bearing 322 and bearing sleeve 529.2

- Remove key 940.4

c) Anti-friction

bearing,

- oil-lubricated - drive side

- with lift-off device -

- If installed - remove cooling and/or circulation line

- Remove key 940.5

- Remove suction side bearing cover 160.1 as described

under a) for axial or radial suction nozzle

- Fix shaft 210 axially on the suction side

- Release bolts 914.5

- Remove bearing cover 360.1 with labyrinth ring 423.2

and limiting ring 380

- Compress spring 950 by moving bearing carrier 382

- Remove circlip 932.3

- Remove bearing 321

- Release bolts 914.4

- Remove bearing housing 350.2 with bearing carrier

382 and spring 950

- Release grub screw 904.1

- Release bearing sleeve 529.3

- Remove circlip 932.2

- Pull spacer sleeve 525 from shaft 210

- Release bolts 914.2

- Withdraw bearing housing 350.1, labyrinth ring 423.1,

bearing 322, bearing sleeve 529.2

- Remove key 940.4

7.4.3.1.2. Dismantling of shaft seal

a)

Stuffing box packing

Dismantle bearings in accordance with 7.4.3.1.1 b) or c)

- Release nuts 920.2

- Slide back the stuffing box gland 452

- Remove packing rings 461

- Remove balancing line

- Release bolts 914.1

- Dismantle sealing casing 441

- Withdraw shaft wearing sleeve 524

b) Mechanical

seal