Goulds Pumps 3311 - IOM User Manual

Page 19

19

7 Maintenance, Disassembly, Assembly

7.1

Prerequisites

The pump or the pump set must have been taken out of

operation in accordance with the instructions of Section 6.

7.2

Safety measures

• Flush the pump thoroughly before disassembly to

purge away the residual liquid left after draining the

pump.

• Ensure that people and the environment are not put at

risk through explosive, toxic, hot, crystalline, or acid

liquids handled.

CAUTION

• The workplace for disassembly or assembly must be

clean.

7.3

Maintenance and inspection

7.3.1 Oil-lubricated bearings

If the driver is on the discharge side, the pumps will be

equipped with oil-lubricated anti-friction bearings on the

drive side and a sleeve bearing lubricated by the liquid

handled on the suction side. If the driver is on the suction

side, the pump will have an oil-lubricated anti-friction

bearing on the suction side. An additional oil-lubricated

anti-friction bearing will be mounted on the discharge

side of pumps equipped with a lift-off device.

Pumps are shipped from the factory without oil in the

bearing housings.

The bearing housings must be filled with oil before initial

start-up.

CAUTION

• Use only very clean and non-ageing oil with good

water separating and corrosion protection properties.

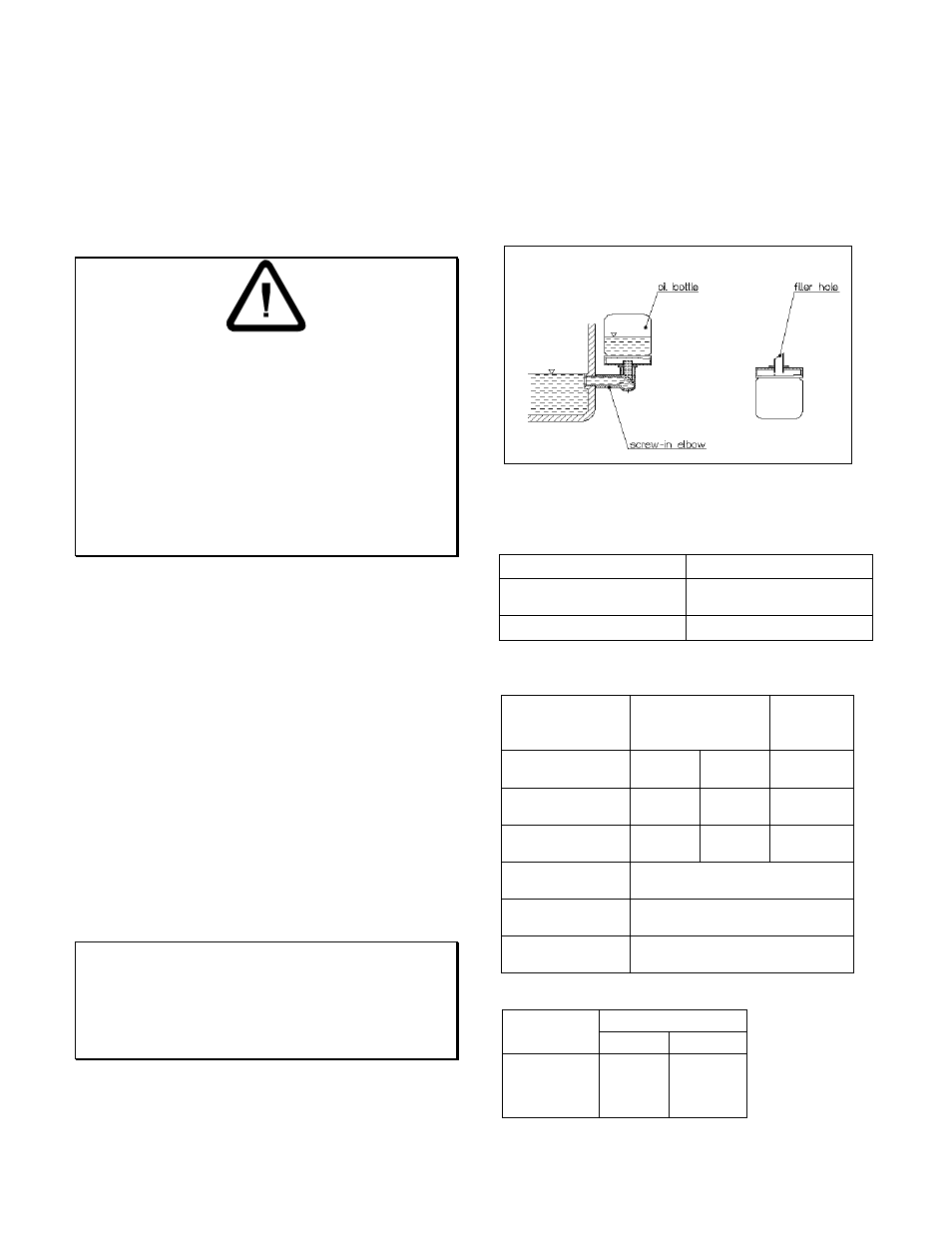

Standard design with constant level oiler

- Pull oil bottle out of the screw-in elbow.

- Fill the bearing housing with oil until the oil becomes

visible in the screw-in elbow.

- Fill oil bottle through filler hole.

- Replace oil bottle. As long as there is oil in the bottle

the oil level in the bearing housing is sufficient.

If the bearings are new, change first oil after about 200

operating hours. Afterwards, change the oil in accordance

with the following table:

light service

normal and severe service

Light contamination,

T < 50 °C

light contamination,

T > 50 °C

Annually

every six months

Use the following lubricating oils:

Bearing temperature

< 80 °C

Ambient

temperature

< 0 °C

n

≤ 1500

rpm

n > 1500

rpm

Lubricating oil acc.

to DIN 51517

CL 68

CL 46

CL 22

Kin. viscosity

at 40 °C in mm²/s

61.2 to

74.8

41.8 to

50.8

19.8 to 24.2

Neutralization

number

≤ 0.15 mg KOH/g

Ash content,

weight-%

≤ 0.02

Water content,

weight-%

≤ 0.1

Oil consumption (l)

Size Lift-off

device

without

with

2x3-7 0.19 0.25

2.5x4-8 0.24 0.30

4x5-11 0.27 0.35