Goulds Pumps 3311 - IOM User Manual

Page 10

10

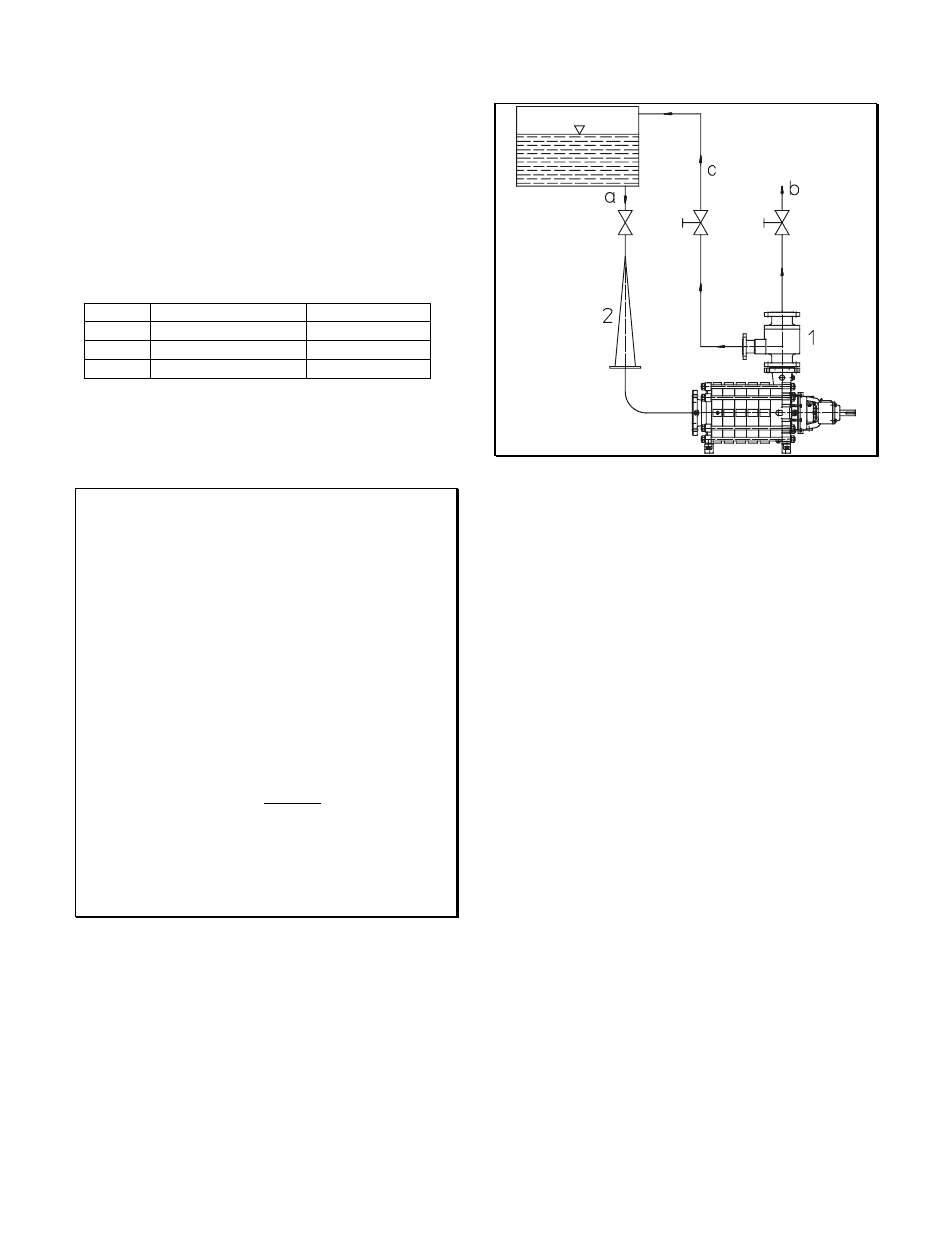

3.1.5 Minimum flow line

The minimum flow line (or bypass line) should be used if

operation with the discharge side shut-off valve closed is

possible. The minimum flow valve ensures that a

sufficient rate is automatically returned to the suction side

tank.

The minimum flow rate is shown on the curves or the data

sheet.

Size

t = 140 °C or lower

t > 140 °C

2x3-7

20 % of Q

BEP

25 % of Q

BEP

2.5x4-8

20 % of Q

BEP

25 % of Q

BEP

4x5-11

25 % of Q

BEP

25 % of Q

BEP

Should exact calculation be required, please contact

Gould’s Pumps.

CAUTION

• Up to the shut-off or non-return valve, the line should

be designed to suit the nominal pressure of the

discharge line, afterwards in accordance with the

design pressure of the feedwater/suction tank.

• Permissible velocity in the minimum flow line: 7 to 10

m/s.

• If an automatic device (bypass non-return valve) is

used, ensure that even in the case of trouble, liquid can

be returned through the minimum flow line.

• Frequent checks are recommended. Early replacement

of the minimum flow valve (which is exposed to

heavy wear) will prevent energy losses.

• The minimum flow valve should be installed near the

pump discharge nozzle, upstream from the discharge

shut-off valve.

• A non-return valve should be installed in the

minimum flow nozzle or the minimum flow line.

• For repair or overhaul work on the pump or the bypass

non-return valve, a shut-off valve must be installed in

the minimum flow line (c).

a Feed line

b Discharge line

c Bypass line

1 Bypass non-return valve

2 Conical strainer

Minimum flow control

3.1.6 Balancing line

The balancing line connects the discharge side shaft

sealing casing with the suction casing. There is no

throttling or shut-off device in this line, which serves to

hydraulically balance the pump.

The balancing line can also be returned by the customer to

the feed tank or the feed line.

3.1.7 Venting during pump priming

Before starting the set, the pump and the suction line must

be completely vented and filled with the liquid handled.

To bleed the air, several holes with plugs have been

provided. Similar holes may be used in the pipework. The

shut-off valve in the suction or supply line must be fully

open.