Goulds Pumps 3311 - IOM User Manual

Page 16

16

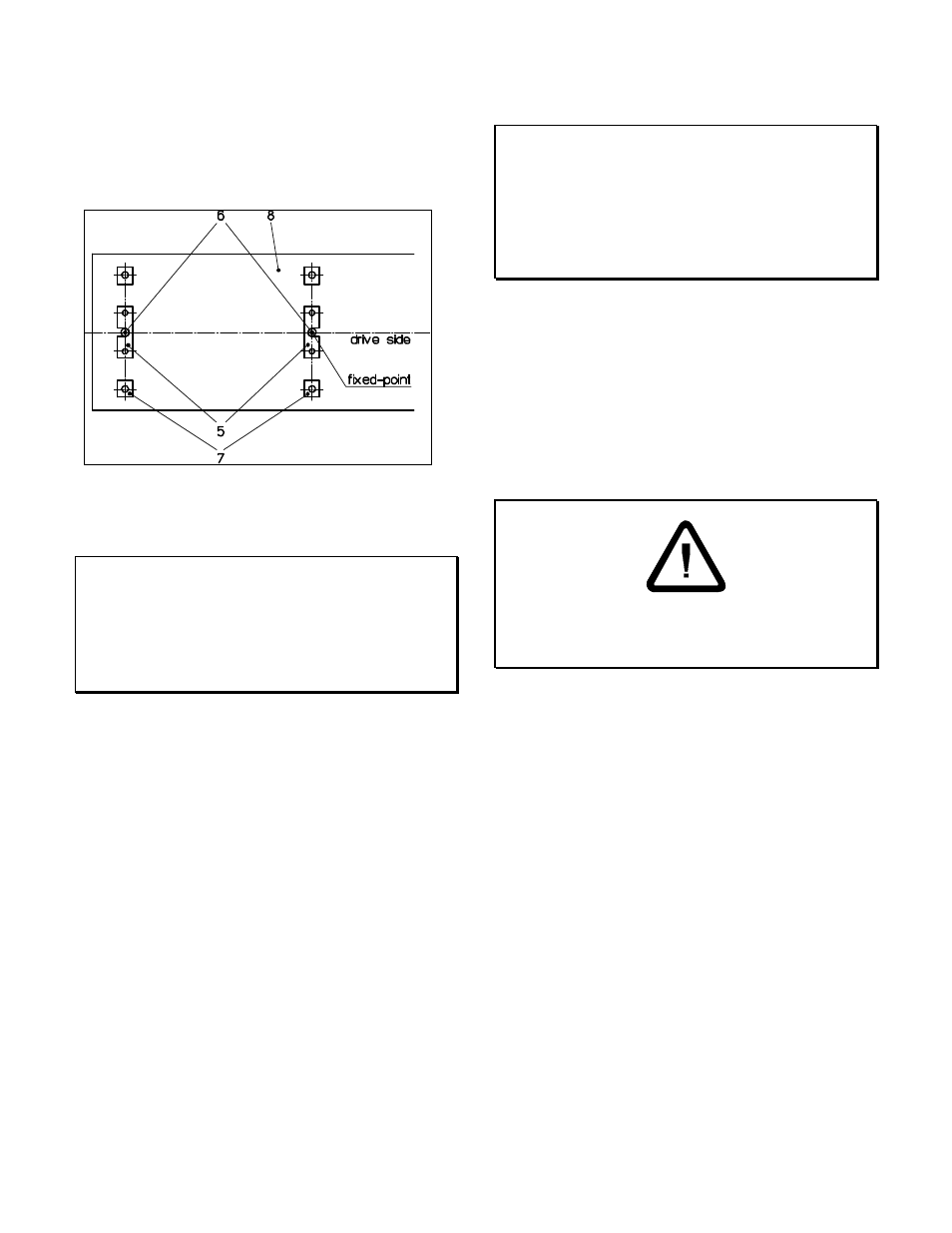

Guide pins (6) on the suction and discharge casing feet

prevent lateral movement of the pump. The drive side

guide pin is held in place by a guide casing which is

bolted to the baseplate (8). The opposite guide pin can

move in a guide casing.

5 Guide casing

6 Guide pin

7 Pump foot support

8 Baseplate

CAUTION

• Avoid distortions when finally tightening the bolts.

• The nuts of the foot fastening must be loosened so far

that the washers can be moved by light hammer

blows.

5.6

Grouting the baseplate

Prior to grouting the baseplate, carry out the following

preparatory work:

- Check the dimensions with regard to height and

alignment of flanges.

- Re-adjust baseplate, if necessary.

Ram earth-humid concrete under the baseplate or add

shrinkage-free grout until the entire space under the

baseplate is filled. Grouting should be a continuous

process so as to ensure that no air pockets form under the

baseplate.

When the grout is set re-tighten the foundation bolts and

re-check the alignment of the coupling.

5.7

Pump installation in the piping system

CAUTION

• The pipework forces and moments acting on the pump

nozzles must not exceed the permissible pump nozzle

loads.

• The pump must not be used to clean the pipework

with chemicals.

- Remove the protection covers from the pump flanges

and the auxiliary pipeline connections.

- Insert the flange gaskets.

- Connect the suction or feed line.

- Connect the discharge line.

5.8

Hydrostatic test

• If the piping system is to undergo a hydrostatic

pressure test, the pump must be excluded from such

testing.

5.9

Cleaning, flushing and pickling of the

pipework

When the pipework is cleaned, flushed or pickled, the

pump must be excluded.